Parts and Performance: Selecting the Right Pressure Regulator for Each Job

by Jeff Hopkins, on 7/26/17 8:30 AM

A pressure regulator is always changing itself as it reacts to the processes going on around it

Learn more about Swagelok pressure regulators and get access to all Swagelok pressure regulator catalogs here >>

Always on the go

If you are used to working with valves, pressure regulators can seem confounding at first. It’s true that there’s a lot more to a pressure regulator and the job that it performs. In this article, we’ll go over some basics that will make it easier for you to select the right pressure regulator for each job. We’ll follow up with more detail about some of the Swagelok pressure regulators available to you.

Functionally, most shut-off valves are relatively simple devices. A valve is either closed or it isn’t. If you know your pressure, temperature, and flow information, most of the time, you can figure out what valve you need. For more complex applications, we have resources to help you select and size a valve.

A pressure regulator, on the other hand, is always changing itself as it reacts to the processes going on around it.

Optimal flow range

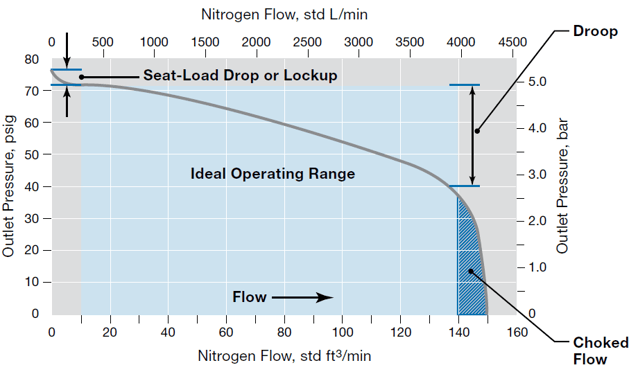

A pressure regulator widens and narrows the inlet opening to make sure you get a consistent outlet pressure within a certain range of inlet pressures and flow conditions. You need to know not only the inlet pressure, but also the pressure you want on the way out (outlet pressure), and how much flow is acceptable. Remember, pressure regulators regulate pressure, not flow.

Each pressure regulator is designed to work best within a certain range of conditions. Bump up against one end of the range, and the pressure will build up enough to close off the inlet. That’s called lockup. Go all the way to the other end of the range, and the pressure regulator will be wide open, and is no longer regulating pressure. That’s called choke flow.

Each pressure regulator has its own optimal flow range (Ideal Operating Range) between lockup and choke flow.

Moving parts

Obviously, there are some moving parts inside. Some models use an internal spring to control outlet pressure. Others control the outlet pressure by means of pressurized gas in a dome atop the pressure regulator.

Spring-loaded pressure regulators are a lower-cost option, but the design is more susceptible to temperature, shock, and vibration. Dome-loaded pressure regulators are more rugged and accurate, but tend to cost more and take up more space. There are also designs that use a combination of spring-loading and dome-loading.

Each pressure regulator has its own optimal flow range (Ideal Operating Range) between lockup and choke flow.

Cause and effect

At Swagelok Northern California, we’re glad to help customers find the appropriate pressure regulator for each job. You can even set up a phone consultation with one of our fluid system experts. But you’ll feel more confident in your choice if you take the time to understand your own systems better, and what you are asking a pressure regulator to do within that system.

Even if you already have a pressure regulator in place, changing conditions may require you to replace it with something slightly different. Here’s why: In any fluid system, you are basically moving a liquid or a gas from Point A to Point B. When changes are made anywhere between those points system, the pressure regulator is suddenly required to operate under new conditions.

If someone has tapped a line downstream of the pressure regulator, that changes the flow characteristics. The same is true if someone has added a line. If your plant has been expanded, the distribution system will draw from your main tanks differently.

The same pressure regulator that was ideal for the original conditions might now be undersized or oversized. Understanding the changes will help you select the pressure regulators you need now. Blueprints of your system can help you understand what’s going on, but only if they’ve been updated to track every change since it was built.

Don’t forget the other elements that go along with pressure regulators -- the filters, CGA connections, pressure gauges, relief valves and more. You want all the parts to match the pressure regulator's performance.

Pressure regulator selection

We covered the basics of pressure regulators in the webinar, Theory and Operation of Pressure Reducing Regulators, and pressure regulator selection in the webinar, How to Select and Size a Pressure Reducing Regulator.

We distilled these two pressure regulator webinars into our Pressure Regulator Selection and Sizing Guide.

We also have an article and video on flattening pressure reducing regulator flow curves, and an article on regulator selection and technical bulletin that has all Swagelok pressure reducing regulator flow curves.

The discussion and resources above apply primarily to pressure reducing regulators. Back pressure regulators are a horse of a different color. Fortunately, we tackled back pressure regulators, how they work and how to use them, in our webinar, Back Pressure Regulators Made Simple.

Need help selecting a pressure regulator, set up a phone consultation with one of our experts.

additional resources

get in touch

In a hurry or have a question? Please click here to get in touch - we respond fast! Or call 510-933-6200.

/Digital%20montage%20(1).jpg?width=1920&name=Digital%20montage%20(1).jpg)