Case Study: Brownie's Third Lung Breathes Easier After Installing Swagelok

by Jeff Hopkins, on 6/29/16 8:00 AM

Crammed into the tight brow area of a 50-foot sport fishing boat with little room to move, Robert Carmichael narrowly avoided a chunk of flying metal that whizzed past his head...at that moment Carmichael decided to look for a new solution.

Get the complete Third Lung case study (PDF), other success stories and how Swagelok Northern California can help your fluid systems succeed at http://northerncal.swagelok.com/success

Reliable Swagelok components saved yacht outfitter from disastrous results

When a valve broke off under 3,000 pounds of pressure and parts of it whizzed past Robert Carmichael's head, he knew it was time to find a new supplier.

When a valve broke off under 3,000 pounds of pressure and parts of it whizzed past Robert Carmichael's head, he knew it was time to find a new supplier.

Carmichael was working on a compressed-air system to fill scuba tanks onboard yachts. These systems are designed, manufactured, and installed by a division of Brownie’s Third Lung of Ft. Lauderdale, Fla.

Carmichael is the company president, but he isn't afraid to get his hands dirty. On this day he was crammed into the brow of a 50-foot sport fishing boat when the valve blew off.

Upon inspection, Carmichael discovered that the fine threads of the NPT valve connection had been marred, possibly during installation. He quickly realized he needed a better way than a threaded connection to contain 3,000 psi of pressure.

Swagelok to the rescue

In his search for a new supplier, Carmichael talked with the owner of a local marine company. That owner introduced Carmichael to a sales representative from the local Swagelok Sales and Service Center in Mulberry, Fla. The company, in turn, introduced him to Swagelok tube adapter fittings, which rely on a two-ferrule mechanical grip design. The front ferrule creates a seal against the fitting body, as well as on the outside diameter of the tube. The seal is also resistant to vibration fatigue, which is particularly important in Brownie’s applications.

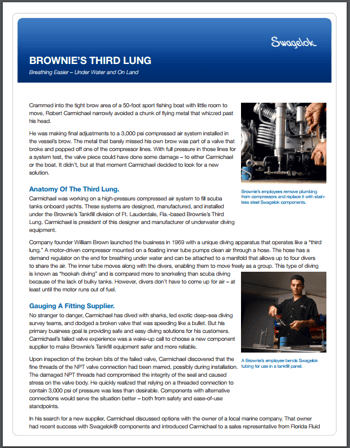

Compressors used in Brownie’s air systems were originally designed for non-marine applications and, therefore, feature materials that do not stand up well to saltwater. To avoid corrosion, Brownie’s replaces the removed plumbing with between 25 and 35 stainless steel components per compressor. And now those components are all from Swagelok.

Fit with a kit

To streamline the Brownie’s assembly process, the local Swagelok Sales and Service Center developed prepackaged kits that include all of the components for a particular compressor. Complete kits arrive in a Swagelok box with each component bagged and numbered individually. An enclosed packing list corresponds with the numbered bags for simple identification. The process helps Brownie’s keep all of the parts for a compressor with the unit.

“Swagelok is our only supplier that provides a service like this. It makes our installers’ jobs much easier,” says Carmichael. “It also keeps them moving on a compressor since all of the parts are there. If one part was missing, the job could be on hold for a few days.”

Prepackaged kits also enable Brownie’s to minimize its on-site inventory of Swagelok parts. The company is able to place orders and expect parts to arrive within a few days.

Proud customer

Brownie’s uses Swagelok pressure gauges, pressure regulators, needle valves, bleed valves, tubing, fittings, hoses, and quick connects. Of these components, about 99 percent are stainless steel. Brownie’s uses a few brass components for low-pressure plumbing on the Third Lung units. The components are primarily 1/4-inch as that size provides a sufficient volume of air at low-flow rates. Brownie’s also uses a limited number of 3/8-inch, 1/2-inch, and metric-sized components.

The majority of Swagelok components used on tank fill systems are hidden behind panels, except for the visible front of the pressure gauges. Brownie’s chose a custom dial face, which includes the company’s logo and Web address to provide a point of contact for service needs.

But the company is proud to tell customers what's behind the panel.

“Brownie’s markets the plumbing and gauges used in on our tank fill units as Swagelok components,” says Carmichael. “Yacht owners are proud of having a diving system onboard and want to know that they bought the best.”

Since Carmichael selected Swagelok, he has never looked back.

“We’re that loyal not just because of the design of the product, but also because of the reliable service we receive. And we know we’ll receive that same level of service and availability of product globally from any other Swagelok distributor if we need components in the field,” says Carmichael.

You may not have had any parts whiz past your head under high pressure. Yet. Don't wait for a weak part to reveal itself. Contact Swagelok Northern California for advice on reliable fittings for your fluid systems.

For the complete Third Lung story (PDF) and access to other case studies click here. To learn how you can tap into the same level of quality, expertise, and service, book a quick phone consultation with one of our design and assembly experts.

Additional Resources

/Digital%20montage%20(1).jpg?width=1920&name=Digital%20montage%20(1).jpg)