Earlier this year, the Swagelok Northern California team got the chance to take part in a truly unforgettable experience — a robot battle. In March, our resident comic nerd and model-builder extraordinaire Victor Jung received a call from Marc DeVidts, co-founder and CTO of Double Robotics. This innovative tech startup, which makes telepresence robots for the commercial market, is home to Team Icewave, as seen on the popular TV show “BattleBots.”

For those unfamiliar with the show, “BattleBots” is a combat robot gladiator event; people gather from all over the world to watch sophisticated remote-controlled machines fight it out in an arena-based elimination tournament. Team Icewave’s bot uses a gas engine to drive a massive, 47-pound hardened-steel death blade, backed by a 360-degree field of mauling power.

Unfortunately, team Icewave’s bot was eviscerated by Ghost Raptor in Season 1, landing upside-down with no way of righting itself. In preparation for Season 2, Marc and the team’s mechanical designer Angie Bamblett came to Swagelok Northern California (SNC) seeking assistance; they needed to add a high-pressure actuator system that would give the bot 2500 psi of gas to flip itself back over if needed.

Victor pulled dozens of parts from our inventory, experimenting through trial and error until everything fit together just right. We (Victor and Neil Ide) utilized special tube adapter fittings to create the perfect compact solution for Icewave. With the work complete, Marc generously invited us to Los Angeles for the taping of Season 2.

On the day of the fight, however, he sent us an emergency text: Icewave had been slightly modified with a couple of anti-flip spikes on the front and would no longer right itself with the current gas pressure. We quickly headed to the 60,000-square-foot builder’s area to brainstorm a last-minute battlefield solution. Because the system used pre-charged N2 cylinders, we had no way of increasing the pressure.

After much deliberation, we decided to use 4500 psi high-pressure gas bottles to charge the bots on-site and put an extra 500 psi in Icewave’s gas cylinder. We grabbed the extra fittings and added a fill line to the already crowded engine compartment.

Before overcharging the cylinder, however, the on-site safety manager had to greenlight the modification. We cut an empty cylinder in half to establish the wall thickness and ensure that the extra 500 psi would be sustainable. Referring to the wall thickness and Swagelok’s data sheets on tubing diameter and wall thickness versus gas pressure, we determined that the carbon steel cylinder could easily handle 3000 psi.

The excitement didn’t end there, though. After charging up the system, we realized our only solenoid valve, a high-pressure aerospace switching valve sourced from eBay, was leaking gas! At that point, so close to the action, it looked like it was “game over” for Icewave. But our team refused to give up. We tore down the valve and cleaned all of the seals and various components. But after reassembling it for testing, the coil wouldn’t power on at all.

Upon inspection, we discovered that we had completely broken one of the coil’s electrical wires out of the epoxy potting. Feeling the nip of defeat at our heels, we doubled down again, smashing the epoxy open with a pair of pliers to expose the magnet wire and painstakingly locating the broken lead. We soldered the connection back together and reassembled the valve. We installed it on the gas cylinder for a midnight test, and, much to our excitement, found that the rebuilt valve worked perfectly!

The next morning, our team had the privilege of grabbing seats right behind the judges for an unbeatable view. Nearly every “BattleBots” fight ended in a fire from shorted-out robots and pulverized lithium batteries. After an intense, action-packed day, we packed up and drove back to the Bay Area, sleeping in shifts.

The Swagelok Northern California team was proud to have played a part in this exciting competition, working around the clock to ensure Icewave’s bot was prepared for battle. We knew critical fluid systems technology was used in a wide range of engineering applications, including particle accelerators, power plants, refineries, semiconductor factories, wineries, fuel cell laboratories, and even hydroponic medical marijuana grow houses — and now, we can add “BattleBots” robots to the list.

Swagelok is not just a valve and fitting company; we proudly serve as a critical process solution partner and are ready to do whatever it takes to solve your unique challenges.

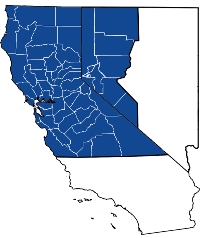

Since 1947, Swagelok Company has designed, developed, and manufactured high-quality, general purpose and specialty fluid system products. Today Swagelok is a $2 billion company with approximately 5,400 associates, 20 manufacturing facilities, 6 global technical centers, and a network of 225 sales and service centers in 70 countries employing about 3,600 sales and service associates. Swagelok Northern California is the sales and service center serving 58 counties of northern California and northwestern Nevada.

Since 1947, Swagelok Company has designed, developed, and manufactured high-quality, general purpose and specialty fluid system products. Today Swagelok is a $2 billion company with approximately 5,400 associates, 20 manufacturing facilities, 6 global technical centers, and a network of 225 sales and service centers in 70 countries employing about 3,600 sales and service associates. Swagelok Northern California is the sales and service center serving 58 counties of northern California and northwestern Nevada.

Call us: 510-933-6200.