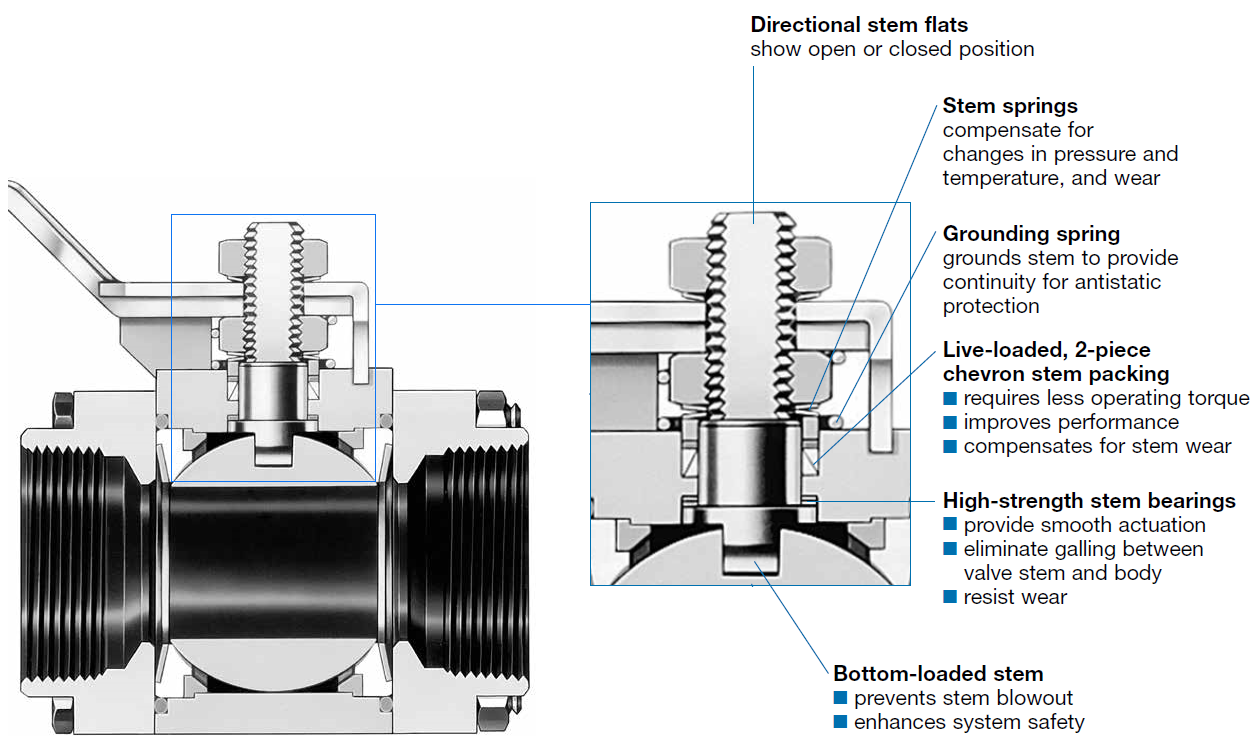

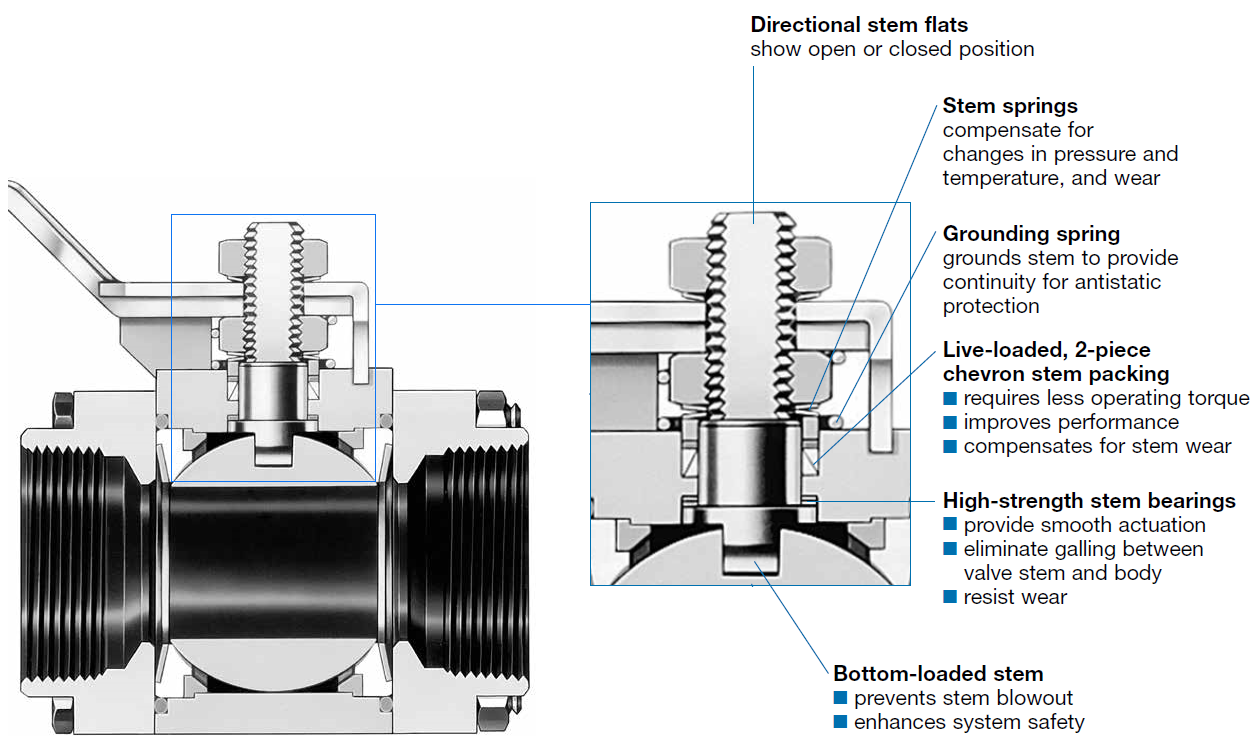

There are several key features of the 60 series ball valve that create a distinct design difference versus a traditional valve design.

Robust seat sealing is accomplished by combining reinforced PTFE with additional seat support and a coned-disc spring.

Robust seat sealing is accomplished by combining reinforced PTFE with additional seat support and a coned-disc spring. - A reliable stem seal is achieved by a two-piece chevron packing live-loaded with Belleville springs.

- Safe operation is ensured through employing a grounding spring and blow out proof stem.

- Our Limited Lifetime Warranty shows our commitment to quality.

Designed to be operated in a fully open or fully closed position

Three ways to learn more

1. Continue reading below the buttons.

2. Get the literature: Fill the form to get quick links to the 60 Series Ball Valve interactive PDF,

quick look, and catalog by email. We keep your email private.

3. Get a hand: Use the buttons below to get help choosing the right valves. Or have us build an

assembly or subassembly for you using exactly the right components for your application.

Traditional Ball Valves

Traditional Ball Valves

When you look at how PTFE is used in a traditional valve design, large portions of the seat are unsupported. Since PTFE is unstable and tends to cold flow, temperature cycling, pressure changes, valve actuation and time in service will actually cause the PTFE to move into the orifice and body cavity. This reduces the force of the seat against the ball and leaks can result.

Example of the effects of cold flow on PTFE that can result from operating a valve in the partially open position for a prolonged period of time, or if the valves are operated under pressure in the partially open position.

Example of the effects of cold flow on PTFE that can result from operating a valve in the partially open position for a prolonged period of time, or if the valves are operated under pressure in the partially open position.

WHAT SWAGELOK HAS DONE WITH THE 60 SERIES IS QUITE A BIT DIFFERENT.

A Seat Seal You Can Rely On For Leak Tight Service

To reinforce the PTFE, we use a unique coned-disc spring-loaded seat to compensate for seat wear, pressure and temperature changes. This design reduces seat wear from pressure surges and seals regardless of flow direction.

To reinforce the PTFE, we use a unique coned-disc spring-loaded seat to compensate for seat wear, pressure and temperature changes. This design reduces seat wear from pressure surges and seals regardless of flow direction.

- The 60 series valve uses a reinforced PTFE seat for additional stability. This helps some, but alone it won’t do the trick.

- Then, we employ a support ring in front of the seat to

protect against seat bulge, premature wear, and deformation.

- The most important difference in the design of our valve is the use of the coned-disc spring behind the seat to achieve live- loading of the seat assembly

By greatly reducing the amount of PTFE that is unsupported, you can count on excellent seat sealing performance.

See How Seat Seals Are Created Under Both Low and High Pressure

Under Low Pressure

Under Low Pressure

Under low pressure, seals are created by the coned-disc spring-loaded seats pushing against the ball. Pressure is not required to create a seal.

A uniform seal is created on both the upstream and downstream seats.

Under High Pressure

Under High Pressure

Under high pressure, the ball is forced downstream, flexing the downstream seat and creating a seal. The upstream seat also flexes with the ball movement and maintains a seal. As the seat is forced downstream due to pressure, the seat spring compresses thus reducing the force on the ball which reduces wear and leads to longer cycle life.

Technology to Assure Stem Sealing

Equally important as the seat seal is how the 60 series achieves a reliable stem seal. There are two elements that are critical to creating the seal.

- We utilize a two-piece chevron packing enabling more of the torque that is applied to the packing nut to be distributed to the contact area with the stem and the body of the valve which is essential for sealing.

- The packing is backed up by a pair of Belleville springs to apply a consistent load on the packing creating a live-loaded stem assembly. The result? Long, trouble-free service over the life of the valve.

Packing: Two-Piece Chevron vs. Conventional

Two-Piece Chevron Packing

Two-Piece Chevron Packing

The two-piece packing in the 60 series valve is what makes it truly “live-loaded.” The two pieces of chevron packing work together to create a robust stem and bonnet seal. As an axial load is applied from the stem nut, it is transmitted radially along the entire length of the packing to the stem resulting in a low actuation torque.

Conventional Packing

In a conventional seal, this load is transmitted at much higher loads with an uneven force distribution, ultimately leading to lower cycle life and higher actuation torques as compared to the chevron packing.

Design Features To Ensure Safe Valve Operation

- The 60 series ball valve employs a blow out proof stem that is assembled from the bottom which prevents stem blowout.

- High-strength stem bearings located between the stem shank and the body are designed to ensure smooth operation and long service life.

- The grounding spring provides a consistent ground to avoid any static build up during operation and use.

- The stepped shoulder prevents stem extraction.

A Promise As Strong As Our Products

The Swagelok Limited Lifetime Warranty demonstrates our relentless commitment to quality and our customers.

Every Swagelok product is backed by this promise for the life of the product.

Protect Your Fluid System Investment from Installation to Everything After.

Robust seat sealing is accomplished by combining reinforced PTFE with additional seat support and a coned-disc spring.

Robust seat sealing is accomplished by combining reinforced PTFE with additional seat support and a coned-disc spring.

Traditional Ball Valves

Traditional Ball Valves Example of the effects of cold flow on PTFE that can result from operating a valve in the partially open position for a prolonged period of time, or if the valves are operated under pressure in the partially open position.

Example of the effects of cold flow on PTFE that can result from operating a valve in the partially open position for a prolonged period of time, or if the valves are operated under pressure in the partially open position. To reinforce the PTFE, we use a unique coned-disc spring-loaded seat to compensate for seat wear, pressure and temperature changes. This design reduces seat wear from pressure surges and seals regardless of flow direction.

To reinforce the PTFE, we use a unique coned-disc spring-loaded seat to compensate for seat wear, pressure and temperature changes. This design reduces seat wear from pressure surges and seals regardless of flow direction. Under Low Pressure

Under Low Pressure Under High Pressure

Under High Pressure

Two-Piece Chevron Packing

Two-Piece Chevron Packing