Mechanical Seal Support

Mechanical Seal Support Assemblies

Swagelok has developed kits and assemblies that help customers protect mechanical seals in rotating equipment by maintaining lubrication and pressure with properly conditioned fluid flows. Collaborate with us to ensure the best match between current needs and Swagelok solution, ensure appropriate flow is maintained, and ensure the proper amount of tubing and tube support materials are on hand.

Please use the button to start a job or get details, or call 510-933-6200.

Improving mechanical seal reliability

Swagelok Seal Support Systems supply either a gas or a liquid to a mechanical seal to regulate the environment in which the seal operates, protecting rotating equipment from damage. These systems provide lubrication to seal faces, control pressure and temperature in the seal chamber and seal, flush the seal of contamination and/or residue build up, and prevent system process fluid from leaking to atmosphere.

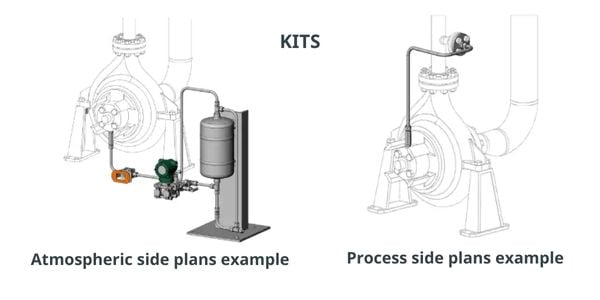

Seal Plan Kits

Seal plan kits (SPK) are a collection of components that are used to connect the seal support plan to the pump. Some API plans are offered only as a kit ready for field installation. Kits include all components needed to complete the plan, eg process side plans 11, 12, 13, 14, 21, 22, 23, 31, 41; and atmospheric side plans 51, 62, 65A, and 65B.

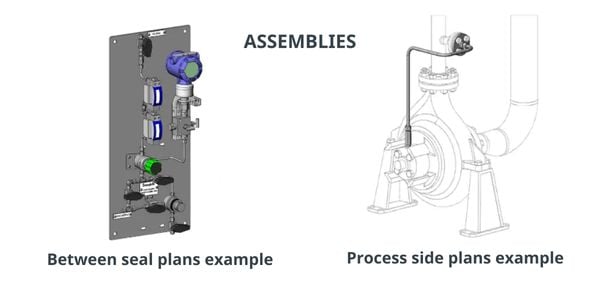

Seal Plan Assemblies

Seal plan assemblies (SPA) are panels, seal pots, or skid systems that comprise the majority of each API seal support plan. Ordering numbering structure allows for users to select a variety of configurations and additional system components to meet requirements. Options and configurations not listed in the ordering numbering structure are also available.

Benefits of collaborating on seal support

Ensuring appropriate flow is critical. For example, it is important to have pressure drop and flow control happen at appropriately engineered locations, such as orifices and flow control valves. Maintaining proper flow and circulation through the support system and seal chamber is key to effective operation. The design of tubing is also key.

There are safety issues to consider as well. For example, when choosing the appropriate design for an API plan, it may be necessary to incorporate block-and-bleed valves on all instruments, including gauges. Last but not least, not all options are listed in Swagelok literature. The addition of isolation valves, bypass loops, and instrumentation are available to assist the pump operator in maintaining the system and monitoring the health of the seal.

With the above issues in mind, let's compare having Swagelok help to handling it in-house:

Professional design

Speed

Product selection

No surprise costs

Documentation

Repeatability

What to expect

These are usually the main steps in producing a custom solution for mechanical seal support:

1. Design

2. Fabrication

3. Quality Control

4. Delivery

We stand behind every assembly

Every Swagelok product, assembly, and solution comes with Swagelok's Limited Lifetime Warranty. Systems use Swagelok components, which are designed and manufactured to the highest quality standards. Per our documented quality process, fabrication is handled by Swagelok-certified associates. Swagelok assembly certification requires that every sample produced earns a grade of 100% from the Swagelok manufacturing engineers who inspect it and put it through destructive testing.

Swagelok Northern California is always reachable. Urgent need? Call 510-933-6200 and listen for "emergency service". This option is staffed around the clock, 24x7, every day of the year.

-1-1.png?width=350&height=350&name=ValuesWheel-Flat_2023_LG%20(1)-1-1.png)

About Swagelok Northern California

Since 1963, Swagelok Northern California has provided thousands of manufacturers, processors, suppliers, and innovators with Swagelok fluid system products and expertise. Over 100 engineers, technicians, trainers, and other professionals make up our local team. With that expertise and $25M worth of Swagelok products in our three local warehouses, we are ready to help you run safe, cost-effective operations.

About Swagelok Company

Established in 1947, Swagelok Company is a global company headquartered in Solon, Ohio. It has 20 manufacturing facilities, 6 global technical centers, and a network of 225 sales and service centers in 70 countries employing thousands of associates.

Request Information/Support

Need details or a quote? We are ready to help.

.webp?width=210&height=70&name=StickyLogo%20(5).webp)