Grab sampling is a vital operation in any petrochemical refinery. The process of safely and consistently obtaining a representative sample is important to ensure product quality as well as compliance with Cal/OSHA and BAAQMD regulations. When I’m working onsite with process and operations engineers in Northern California refineries, I’m always impressed by the number and variety of grab sampling stations located throughout the refinery. It takes a significant amount of process knowledge and real-world experience to be competent in determining the right grab sampling system. Process phase (liquid or gas) and pressure, fluid chemistry, temperature, infrastructure, and distance from the analyzer need to be factored into the design of any grab sampling panel.

Learn directly from the experts in this hour-long webinar Understanding Liquid Grab Sampling Systems. The webinar covers requirements for designing a high-performing liquid grab sampling system, and tips to find a grab sampling system that meets your needs.

For engineers new to refineries and grab sampling, the following information provides a highly condensed grab sample panel application guide. As you review this information, keep in mind that the optimum grab sampling systems are designed with the guidance of knowledgeable process engineers and an experienced grab sampling system vendor. I don’t say that to be self-serving. I’ve just seen too many poorly-designed and implemented grab sampling panels that undermined their real purpose, that is to reliably, efficiently, safely, and consistently provide a representative sample.

Liquid or Gas, Pressurized or Non-Pressurized?

The simplest way to categorize grab sampling panel applications is by fluid phase (liquid or gas) and pressure. The majority of grab sampling panel applications in a refinery will involve high-pressure, high-temperature hydrocarbon liquids, but you’ll also have simpler grab sampling panel applications such as monitoring wastewater. In those cases, there’s no need to keep the sample pressurized. And between those two examples, there’s a spectrum of grab sampling panel applications.

As you read through the information below, a few definitions will help you to better understand the functionality and use cases.

Continuous Flow: This ensures that sample fluid has not been sitting stagnant in tubes leading to the sample panel. The continuous flow (also known as fast loop) design captures a sample that is fresh from the process fluid flow. It can also be used when there is a long tubing run leading to the sample panel.

Purge: Some fluids leave a residue or contaminate the lines if not flushed. Purging introduces a fluid (gas or solvent) to remove residual contamination from the sample lines, dispensing needle, and any internal tubing. Purging can take place before and/or after collecting a sample.

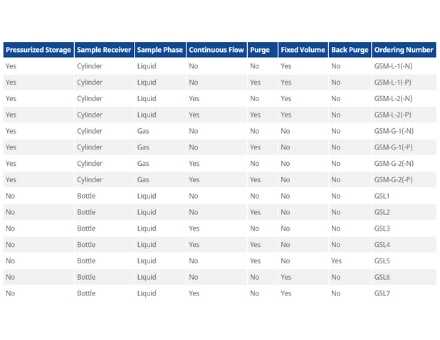

Grab Sampling Panel Applications (Pressurized Container)

-2.png?width=241&name=image4%20(1)-2.png)

A grab sampling panel takes gas or liquid samples at process pressure and maintains the samples in a sealed, pressure-containing cylinder for transport to the analyzer. This panel design uses quick-connects and hoses to attach and detach the cylinder quickly and easily. For durability, the cylinder sits in a saddle system for proper alignment. For some fluids, an increase in ambient temperature as the cylinder is transported to the analyzer can increase the fluid pressure within the cylinder. To avoid over-pressuring, rupture discs are standard on cylinders. Relief valves and expansion chambers are also available options.

|

Standard Sample Panels

During the sampling process, the standard panel stops the sample transport flow.

|

|

Liquid

|

Gas

|

|

Without Purge

|

With Purge

|

Without Purge

|

With Purge

|

|

Non-toxic fluids that will not settle in the sampling system

|

Toxic fluids or fluids that settle in the sampling system

|

Non-toxic gases;

|

Toxic gases or condensable hydrocarbons

|

|

Continuous Flow Sample Panels

During the sampling process, process fluid flows continually from inlet to outlet and the production process continues during sampling with no downtime.

|

|

Liquid

|

Gas

|

|

Without Purge

|

With Purge

|

Without Purge

|

With Purge

|

|

Non-toxic fluids that will not settle in the sampling system

|

Toxic fluids or fluids that settle in the sampling system

|

Non-toxic gases

|

Toxic gases or condensable hydrocarbons

|

Grab Sampling Panel Applications (Non-Pressurized Container)

.png?width=300&name=image2%20(1).png)

When you’re sampling non-pressurized fluid you’ll typically use a non-pressure bottle (glass or polyethylene) to contain the sample and safely transport it to the analyzer. The fluids (water or low vapor-pressure) sampled are not at risk of evaporating or fractionating when stored at atmospheric pressure. Samples are typically collected using a process/vent needle system with a self-sealing septum cap to simplify the sampling process and secure the fluid during transport. Bottles offer a cost-effective method for safely and reliably retrieving samples in most chemical and refining operations.

|

Simple

|

Continuous Flow

|

|

Without Purge

|

With Purge

|

Without Purge

|

With Purge

|

|

Non-toxic liquids

|

Non-toxic liquids that may settle in the sampling system

|

Non-toxic liquids

|

Non-toxic liquids that may settle in the sampling system

|

|

Back Purge

|

Fixed Volume

(Standard or Continuous Flow)

|

|

Non-toxic liquids with long stagnant lines leading to the sampling panel; Purge gas must be compatible with the process fluid.

|

Sample fluid is under high pressure or hazardous; Ensures that 60-80% of the container is filled with the sample fluid

|

Fixed volume grab sampling panels improve safety by separating the process pressure from the sample bottle and the user. The sample is first drawn into the fixed volume reservoir, held there, then transferred into the sample container. The fixed volume method prevents over-filling and overpressure conditions. The continuous flow option is preferable when long sample transport tubes are used.

Grab Sampling Panel Applications Must Consider these Factors

Grab sampling panels need to be tailored to the specific process conditions, fluid characteristics, infrastructure, safety factors, certification standards, and regulations in place in your refinery. To obtain the most consistent, safe, and reliable performance for any of the grab sampling panel applications mentioned above, you’ll need to factor in several key variables that influence the design of a grab sampling panel.

I’ve found that a collaborative effort between process engineers and field engineers, like myself, in evaluating these factors, yield the best outcomes. We each bring an area of expertise to the table. Here are some of the key factors that come up in almost every grab sampling panel application project.

Phase: Cylinders or bottles can be used for liquid samples. Gases, volatile liquids, and toxic/hazardous fluids are better handled in cylinders. Non-toxic, non-volatile fluids can be handled in bottles.

Pressure: What is the pressure in the process flow? Does pressure present any safety issues? Does pressure need to be reduced during the sampling process? If so, how much? Will the locations of sampling input and output ports provide sufficient flow for continuous flow sampling stations or does a pump need to be employed? What cylinder type and volume are required to handle the expected pressure? Is a rupture disc sufficient to handle the over-pressuring of the cylinder or should a relief valve be added?

Temperature: How will high temperatures affect sampling safety? Does the input line need to be heated (viscous fluids) or cooled (high-temp hydrocarbons) for safety or to provide a manageable representative sample? Sample temperature should be below 140°F to comply with HSE safe handling rules. How does temperature affect the sample pressure as it is transported from the sampling panel to the analyzer?

Infrastructure and Ergonomics: Grab sampling panels should be designed for easy accessibility for sampling, testing, and routine maintenance. The location of the panel relative to the sampling port determines the length of tubing runs. Long runs will require continuous flow or purge design. Sample cylinders and bottles should be vertically oriented to avoid contaminated samples. Bottle vents should be positioned away from operating personnel.

Dead Legs: Grab sampling panel design should avoid dead legs (aka dead volume) tubing or piping runs that trap process fluid. Dead legs are found in poorly designed sample valves, dead-ended sample lines intended to drain, and other sampling station components. Dead legs jeopardize sampling quality and consistency.

Grab Sampling Panel Applications Guided by Decades of Experience

Process engineers understand the need for consistent, quality sampling. Swagelok, with decades of experience in designing, assembling, and testing, fluid sampling, and control systems for the petrochemical industry understands how to translate your sampling requirements into the right grab sampling panel designs. To the greatest extent possible, designs incorporate automation to minimize manual steps and protect operations personnel from risks.

Our Field Engineers can consult with you onsite or virtually to assess your needs, turn those requirements into detailed grab sampling panel drawings for your review, and upon your approval, assemble the panels using the highest quality components and fully test the system before delivery.

To find out more about how Swagelok Northen California can assist you in determining the right grab sampling panel applications for your refinery providing expert onsite consultation, contact our team today by calling 510-933-6200.

.jpg?width=600&name=Grab-Sampling-Panel%20(1).jpg)

-2.png?width=241&name=image4%20(1)-2.png)

.png?width=300&name=image2%20(1).png)