For more than five decades, Swagelok has provided high-quality fluid system components and support to semiconductor fab equipment manufacturers to help them maintain the precision and cleanliness required in this industry. As semiconductor fab equipment gets more precise, maintaining process cleanliness becomes more challenging. To meet the industry's ever-changing needs, fabs must create production environments of uncompromising precision and cleanliness. Our components help the semiconductor industry increase chip yield and quality, reduce lifecycle costs, and maintain safe operations.

Products for Semiconductor Fab Equipment

Many kinds of semiconductor fab equipment are used throughout the fabrication process, including diffusion systems, ion implantation equipment, oxidation systems, epitaxial reactors, physical and chemical vapor deposition systems, etching equipment, and photolithography equipment. This equipment is inversely proportional in size to the chip dye size and is responsible for depositing and removing extremely precise, microscopic amounts of material on and from the wafer.

This kind of precision demands the highest-quality systems and components. Fortunately, that's just the business we're in. Swagelok components for semiconductor fab equipment include:

- Valves: high-performance UHP ALD valves for atomic layer deposition production as well as other diaphragm valves, bellows valves, check valves, and specially configured valves and accessories, such as monoblock assemblies

- Fittings: high-purity weld fittings and metal gasket face seal fittings

- Hoses and flexible tubing: insulated hoses for thermal management, convoluted metal tubing, and PFA flexible tubing designed for semiconductor production

- Regulators: spring- and dome-loaded pressure-reducing regulators and compact high-purity, high-flow gas regulators

- Filters: Swagelok UHP inline gas filters remove particulate contaminants

Vacuum Face Seal Fittings for Ultrahigh-Purity Semiconductor Applications

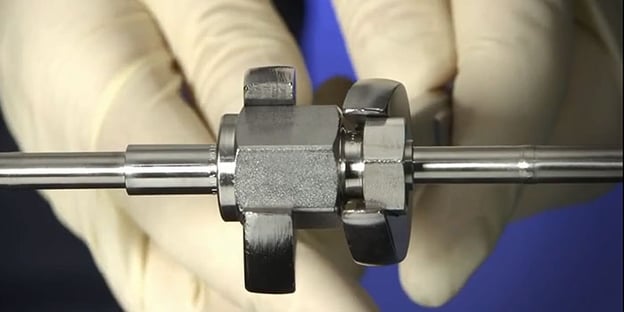

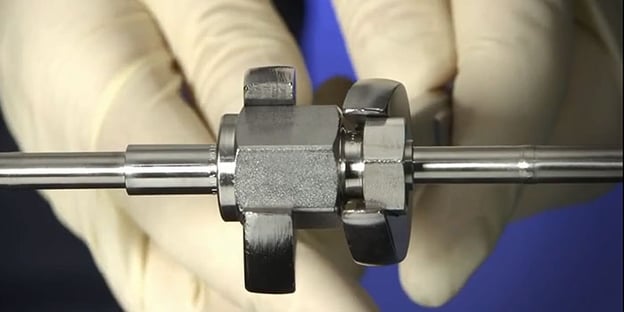

In ultrahigh-purity (UHP) applications, fittings and connections are critical. Though UHP systems are often welded to minimize the possibility of leakage, certain connections must be periodically remade for maintenance or replacement.

Vacuum face seal fittings are one solution for these applications. Swagelok VCR metal gasket fittings are the preferred fittings in the semiconductor industry for high-purity gas delivery systems. These fittings provide the reliability of an all-metal seal, offering leak-tight performance with a vacuum-to-positive-pressure design. They are considered to be “zero-clearance” fittings, with the ability to be dropped in without having to pull back on the tubing to make it fit the gap. Vacuum face seal fittings help ensure system cleanliness by minimizing entrapment areas. Options include higher-grade stainless steels to improve corrosion resistance and surface finish treatments like electropolishing for enhanced cleanliness.

Diaphragm-Sealed Valves

Diaphragm-sealed valves minimize entrapment areas and facilitate purging to improve semiconductor fab equipment cleanliness and efficiency while allowing simple flow shutoff. Our all-metal, diaphragm-sealed valves are available in a wide variety of sizes, materials, and configurations for any high-purity and ultrahigh-purity application.

Swagelok diaphragm-sealed valve offerings include:

DP Series: Springless diaphragm valves for high performance

- Suitable for ultrahigh-purity applications

- 316L VIM-VAR stainless steel body

- Low-pressure and high-pressure models

- VCR, tube butt weld, and modular surface-mount end connections

- Manual or pneumatic actuation

DF Series: Springless diaphragm valves for high flow

- Flow coefficient of 0.62

- 316L VAR stainless steel body

- Fully swept flow path enhances purging

- Minimal PCTFE volume minimizes gas adsorption and desorption

- Fully contained seat insert increases cycle life

ALD Series: Diaphragm valves for atomic layer deposition

- Ultrahigh cycle life with high-speed actuation

- Electronic actuator position-sensing option

- Suitable for ultrahigh-purity applications with 316L VIM-VAR stainless steel body

- VCR, tube butt weld, and modular surface-mount end connections

DL and DS Series: Diaphragm valves offering packless, all-metal containment for high-purity and ultrahigh-purity applications

- Position indicator ring provides visual confirmation that the valve is fully open or closed

- Splined handle and actuator prevent handle slippage and assure positive valve actuation

- DL series diaphragm valves require just one-quarter turn to actuate from fully open to closed

- DS series diaphragm valves require approximately one and one-half turns to actuate from fully open to closed

UHP Regulating and Filtering

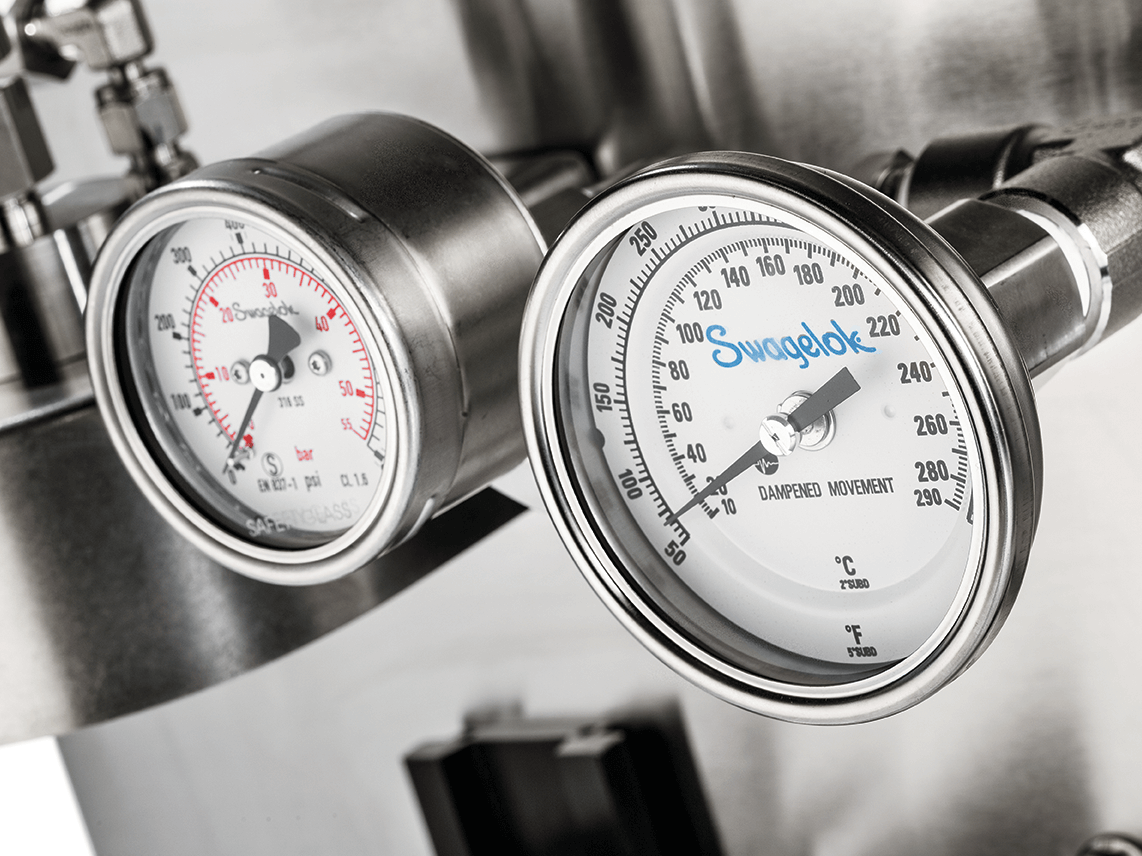

HF Series Regulators: High-Purity, High-Flow Gas Regulators

Selecting a pressure regulator for semiconductor fab equipment is another critical decision in a high-purity fabrication environment. HF series high-purity, high-flow manual gas regulators provide precise pressure control in high-purity, high-flow semiconductor fab equipment. These regulators feature a load spring that interacts with a unique pressure-sensing assembly to precisely control outlet pressure. There are also dome-loaded regulators in the HF series, which also come preset. The compact size and narrow-profile handle make pressure adjustment easy even in tight spaces.

SCF Series Filters: Ultrahigh-Purity (UHP) Gas Filters

With its proprietary Membralox ceramic element and 316L VAR stainless steel housing, the SCF series UHP gas filter is a solution for many demanding gas filtering applications. These ultrahigh-purity gas filters provide efficient particle removal with exceptionally low particle shedding, superior moisture dry-down characteristics, and extremely low outgassing. High-grade stainless steel and inline, all-welded construction ensure outstanding chemical compatibility in any semiconductor fab equipment application.

Top Quality Swagelok Components and Service for Semiconductor Fab Equipment

Swagelok has been providing semiconductor fab equipment manufacturers and operators with innovative, high-tech components and systems since the early days of Silicon Valley. Our VCR metal gasket face seal fittings were designed specifically to solve the unique challenges of UHP gas handling in semiconductor fabs, and we continue to innovate and rise to the challenges of the ever-evolving semiconductor industry.

Interested in learning more about Swagelok valves, fittings, and other components for semiconductor fab equipment? Our specialists are ready to help.

To find out more about how Swagelok Northern California can help with all your semiconductor fab equipment component needs, contact our team today by calling 510-933-6200.