The manufacturing process involves the efficient use of over thirty different gases—one of the broadest range of gases used for any industry—to shape a semiconductor’s electrical properties at the molecular level. Some of the gases involved include nitrogen, hydrogen, oxygen, and argon. These gases need to be precisely applied at each step of the manufacturing process to produce desired reactions.

Understanding the role of gases helps manufacturers acknowledge the importance of a reliable gas delivery system in semiconductor fabrication.

The Role of a Reliable Gas Delivery System in the Semiconductor Industry

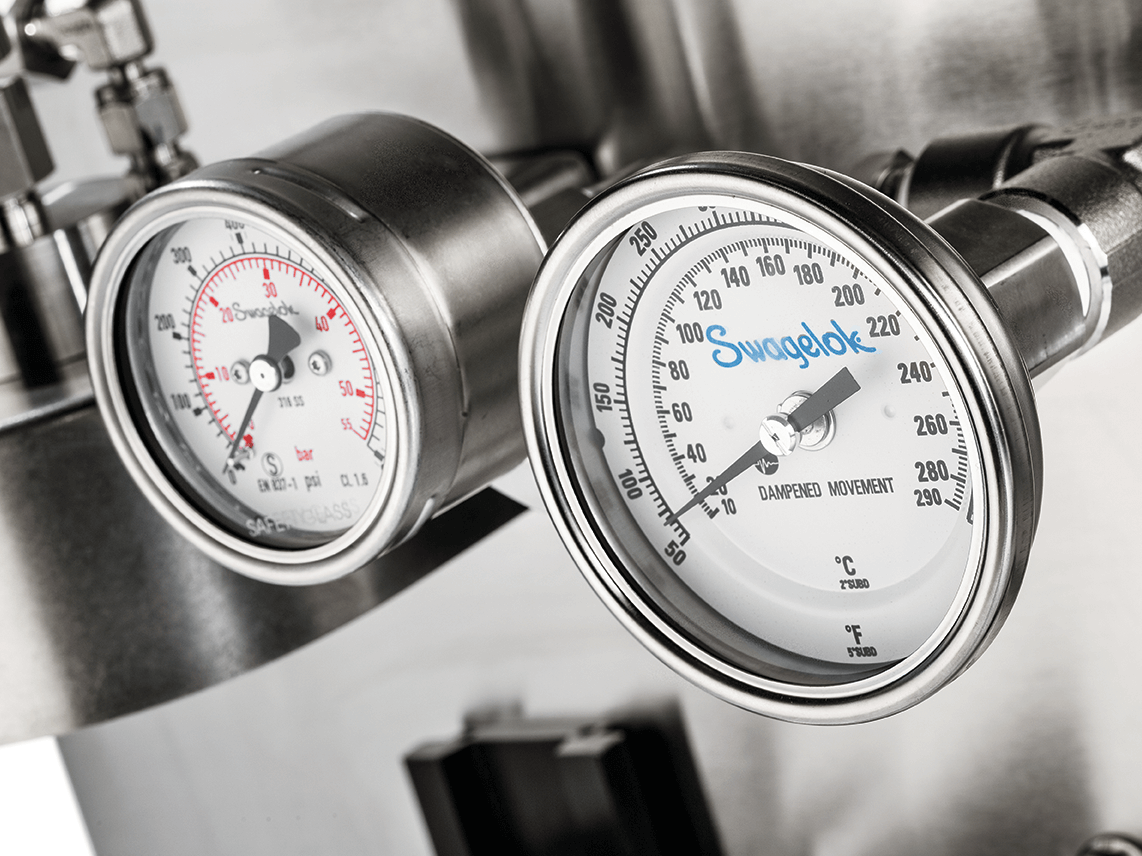

Each stage within the semiconductor manufacturing process requires precise management of gas flow rates and temperature. One of the critical phases is the thin film deposition process. It involves adding a very thin film layer—ranging from fractions of a nanometer to a few atoms—to save the semiconductor from corrosion and accidental scratches. Out of all options to achieve the same, sputtering is widely preferred where target material is bombarded with high-energy particles in a vacuum chamber containing an inert gas—usually argon.

However, it may come with many challenges, requiring skillful adjustment of gas and pressure. For example, the coating may appear dark if the purity of the inert gas is less than 99.9995%, the inflation system has leaks, or if the gas discharged is not as per the required parameters. Thus, it requires a special type of primary gas control system with high-performance control technology for precise management.

Things To Look For While Selecting a Gas Delivery System

Here are some critical attributes to keep in mind while selecting a gas delivery system:

1. Technicality

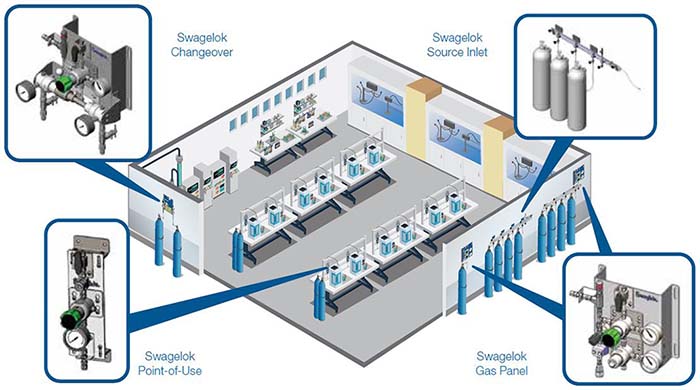

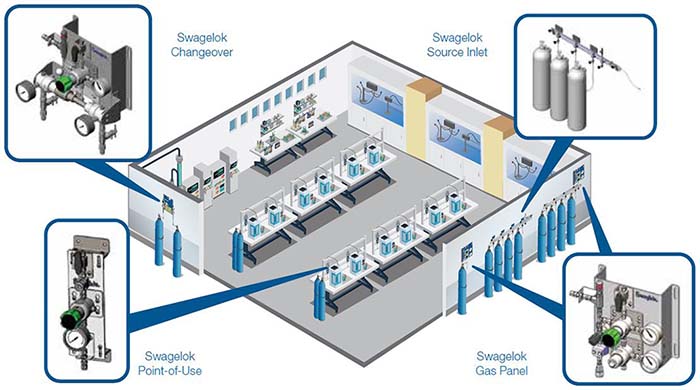

For a hassle-free operation, the gas distribution system must have four essential elements under check: source inlet connection, point-of-use, primary gas pressure control, and automatic changeover. The source inlet should be built with the right components to successfully carry the gas and safely feed it into the primary gas pressure control or automatic changeover systems without any leaks. On the other hand, the point-of-use must offer convenience to operators for adjusting pressure to the required levels with ease.

The automatic changeover must make it easy for operators to switch between the primary and secondary sources without interrupting the gas supply to the system. In this regard, Swagelok Changeover (SCO) allows for a wide range of changeover pressures with a simple serviceability design to minimize maintenance downtime, if needed.

2. Safety

An ideal delivery system brings down the high gas pressure at the source to a usable condition at the point of use. It also facilitates safe working conditions minus any leak. With this in mind, it’s important to choose the proper components for any replacement during breakdown or maintenance as two components with the same operations ratings may have different purposes and applications. A single wrong choice can lead to huge pressure spikes coupled with hazardous conditions.

3. Reliability

To ensure a reliable gas delivery system under variable test conditions, it is imperative to properly size pressure control valves and regulators. Otherwise, the system may underperform within the most important pressure and flow ranges and may require frequent modifications. At Swagelok, we manufacture and assemble reliable and customizable components following ISO 9001 standards that best fit the operation parameters.

4. Budget-friendly

A semiconductor manufacturing process requires the careful use of a few expensive gases, such as helium and hydrogen. That implies, the system must ensure a leak-proof operation in the long term to save you from fiscal losses. For example, you should go for a gas distribution system with compression fittings over threaded connections to minimize the potential of costly leakage.

5. Quick Access and Easy Replacement

If the gas delivery system in a semiconductor unit fails, it is likely to impact the remaining procedures down the line; especially when the point of impact is yet to be identified. Additionally, difficulty in accessing critical checkpoints of the system further increases the downtime. An easy system design enables technicians to quickly access the affected parts, troubleshoot them, and get the system up and running much quicker.

| Swagelok has a vast inventory of tools and equipment that can be used to ensure the quality, purity, and pressure of the gas supplied within a semiconductor fab environment. |

Swagelok’s Modular Gas Delivery System for Semiconductor Manufacturers

When it comes to integrating a reliable gas delivery system in semiconductor units, Swagelok offers four different types of standard subsystems:

|

SSI- Swagelok Source Inlet

|

SSI is designed to handle heavy pressure (up to 300 bar) coming from the gas bottles into the panel through a filter. It connects the bottles to the first stage of regulation. This system features highly customizable settings to purge or vent gases while changing bottles or configuring gases from one bottle to other bottles manifolded together.

|

|

SGP- Swagelok Gas Panel

|

SGP is the main distribution panel to lower the supply gas pressure for distribution around the entire network. As an initial point of control, the panel can be customized with either single- or dual-stage pressure regulators with many series relief valve and series ball valve options. SGP’s modular panel is easy to service and maintain. It can be paired with an SSI to deliver to SPUs.

|

|

SCO- Swagelok Changeover

|

Often used in conjunction with two SSIs to deliver to SPUs, the SCO is designed to ensure the continuity of gas supply by drawing gas from the secondary source when the primary source equals the set changeover pressure. It automatically switches between the sources and offers the flexibility to set changeover pressure to your specification. As a result, it ensures maximum utilization of the gas in the bottles without leaving any residue which counts as a loss. It also comes unregulated, which would lead into an SGP.

|

|

SPU- Swagelok Point of Use

|

SPU, supplied by an SGP or SCO, provides standardization and consistent operation at the point of control prior to the gas being used. It features a compact design with a variety of mounting options to facilitate easy installation at locations where space restriction is one of the major concerns. Swagelok’s SPU can be customized to top-to-bottom flow or vice versa to facilitate specific work requirements.

|

Each of these systems has been designed with high-quality, leakproof Swagelok components to ensure a reliable gas supply.

Select the Best Gas Delivery System for Your Semiconductor Manufacturing Needs

Swagelok has been an ideal equipment supplier for Northern California semiconductor manufacturers for over a decade. As an ideal supplier, we help you choose the right components for designing a leak-proof gas delivery system to increase the reliability of your semiconductors in the market. Furthermore, we have A-Z tools, resources, and expertise to help you design and install a safe gas distribution system without hassle.

If you’re unsure about your existing gas distribution system or looking for better ways to keep it running, our Field Engineers can help you. They can evaluate the existing system and recommend the most ideal components or develop management programs to best meet your specific needs. Our qualified Field Engineers are available to guide you online or at your facility throughout the year.

To find out more about how Swagelok Northern California can help you with selecting a gas delivery system for your semiconductor manufacturing needs, contact our team today by calling 510-933-6200.