Moore’s Law predicts the number of transistors on an integrated circuit doubles about every two years, leading to exponential growth in computing power. The semiconductor industry has largely followed this trend, but as chips get smaller and more complex, thermal management challenges increase, demanding new technologies to keep up.

With the current burden of global chip shortages, it has never been more important for semiconductor fabrication equipment to have the highest possible productivity, reliability, and technical capability. This requires taking on thermal management challenges with new technologies that can meet thermal demand, improve equipment insulation, and prevent coolant leaks.

Why Is Thermal Management So Important?

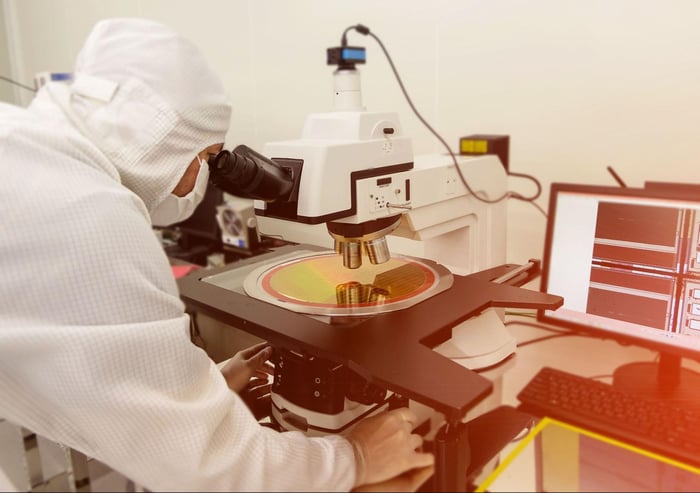

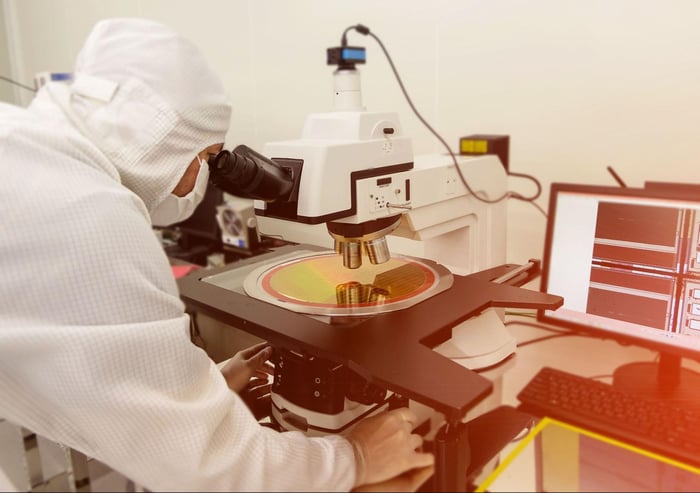

Thermal expansion is a concern in any precise manufacturing operation. Changes in temperature cause materials to expand or contract, and even slight temperature variations can cause the extremely thin films of material deposited on silicon wafers to shift. This is known as edge placement error (EPE), and it can cause chips to fail through misalignments.

Thermal expansion is a concern in any precise manufacturing operation. Changes in temperature cause materials to expand or contract, and even slight temperature variations can cause the extremely thin films of material deposited on silicon wafers to shift. This is known as edge placement error (EPE), and it can cause chips to fail through misalignments.

Other properties of thin films, such as conductivity and elasticity, are also temperature-dependent. That means without the ability to maintain a uniform, controlled temperature, it is impossible to precisely control and measure these properties. Considering the nanometer scale of wafer fabrication, it is extremely important to control thermal effects to meet manufacturing tolerances.

The demand for higher throughput and increased packaging density only increases thermal management challenges. New technologies in thermal management enable manufacturers to ensure uniform production and repeatable measurement by precisely controlling every aspect of the thermal management system.

Increasing Thermal Demand

Semiconductor fabrication equipment can have a range of cooling demands depending on the part of the fabrication process involved. Thermal demand can reach hundreds of kilowatts for liquid-to-liquid cooling applications, and the necessary temperature setpoints can be as low as -100°F.

Major thermal management challenges arise from new technologies that enable ever-shrinking die sizes. To get more transistors on a single die, you need to make them smaller and smaller. As die sizes get smaller, individual transistors become smaller and more tightly packed, increasing thermal demand. As chips continue to shrink, having precise, high-performing thermal management equipment becomes even more critical.

Avoid Issues by Using Well-Insulated Components

No matter how precise your TCUs are, your thermal management system is only as good as its insulation. To minimize heat transfer between process gases and the environment, piping, tubing, hoses, and other gas distribution system components must be well-insulated.

No matter how precise your TCUs are, your thermal management system is only as good as its insulation. To minimize heat transfer between process gases and the environment, piping, tubing, hoses, and other gas distribution system components must be well-insulated.

Insulation also minimizes heat loss over the length of the pipe, tube, or hose and keeps the media temperature uniform. Cryogenic fluid temperatures naturally rise during transportation from the chiller to the processing environment. If hoses, pipes, and tubing are not equipped with the proper insulation, process temperatures may not be optimal. A lack of proper insulation means higher energy expenditure is required to maintain required temperatures.

Good insulation helps piping and tubing systems:

- Enable more precise temperature control

- Conserve heat

- Improve energy efficiency

- Reduce thermal demand

- Reduce media loss

- Improve yield

Prevent Condensation

Cryogenic fluids can cause condensation on the outside piping and tubing. This condensation can be a major thermal management challenge for semiconductor manufacturers, not only because it can jeopardize nearby equipment and processes, but because it can conceal leakage of the volatile and hazardous fluids used in the manufacturing process. Any fluids detected outside the system are viewed as potential manufacturing hazards, which can require the equipment to be shut down until determined safe.

To prevent condensation, proper insulation must be implemented to keep component surfaces at ambient temperature while maintaining the required media temperature within.

Insulation Types

When selecting insulated components, it is important to choose insulation material designed specifically for the temperatures it will be exposed to. While some products may claim to effectively insulate in both hot and cold fluid applications, the truth is that all insulation materials perform differently depending on the process and temperature. For example, a flexible polyethylene jacket performs better in cold temperatures than a fabric jacket, which performs better at high temperatures.

PVC-jacketed tubing is an economical choice for installation temperatures as low as -10°F and operation temperatures as low as -30°F. It also provides good protection against corrosion, abrasion, and UV radiation. For lower installation temperatures—as low as -40°F—urethane jackets can be used. Other insulation materials include PTFE, silicon, and aerogel.

Pre-insulated tubing is available and offers a convenient, economical insulation solution. Electric-traced and steam-traced, pre-insulated tubing bundles maintain a consistent process temperature for a variety of applications. Furthermore, pre-insulated tubing is cost-effective compared to field tracing and insulating, and it is easier to route and connect in the field than cabled bundles.

Semiconductor manufacturers looking for cost savings should consider looking beyond the expensive equipment at the center of their processes to find other, less obvious opportunities for improvement, like component and assembly insulation. Evaluating the insulation of piping, tubing, and hoses and upgrading to more effective options can be a very cost-effective way to improve efficiency and performance.

Look for component suppliers who understand the range of different insulation materials available and know which types work best for different applications. That way, you’ll be sure to choose insulated components optimized for their specific production environments.

Undetected Coolant Leaks Affect Heat Transfer, Too

The thermal management demands of semiconductor manufacturing require specialized heat transfer fluids. Liquid perfluorinated compounds (PFCs), like Fluorinert, are commonly used as coolants throughout the fabrication process because of their thermal conductivity, dielectric strength, and chemical inertness.

While these fluids are excellent coolants, they also tend to have high vapor pressures and low surface tension—which means they evaporate and leak easily. Fluorinert does not present a serious safety hazard, but a leak does mean loss of coolant and unwanted temperature variations. Therefore, it is essential to minimize the potential for leaks by using appropriate leak-resistant or leak-proof components and fittings wherever these fluids are used.

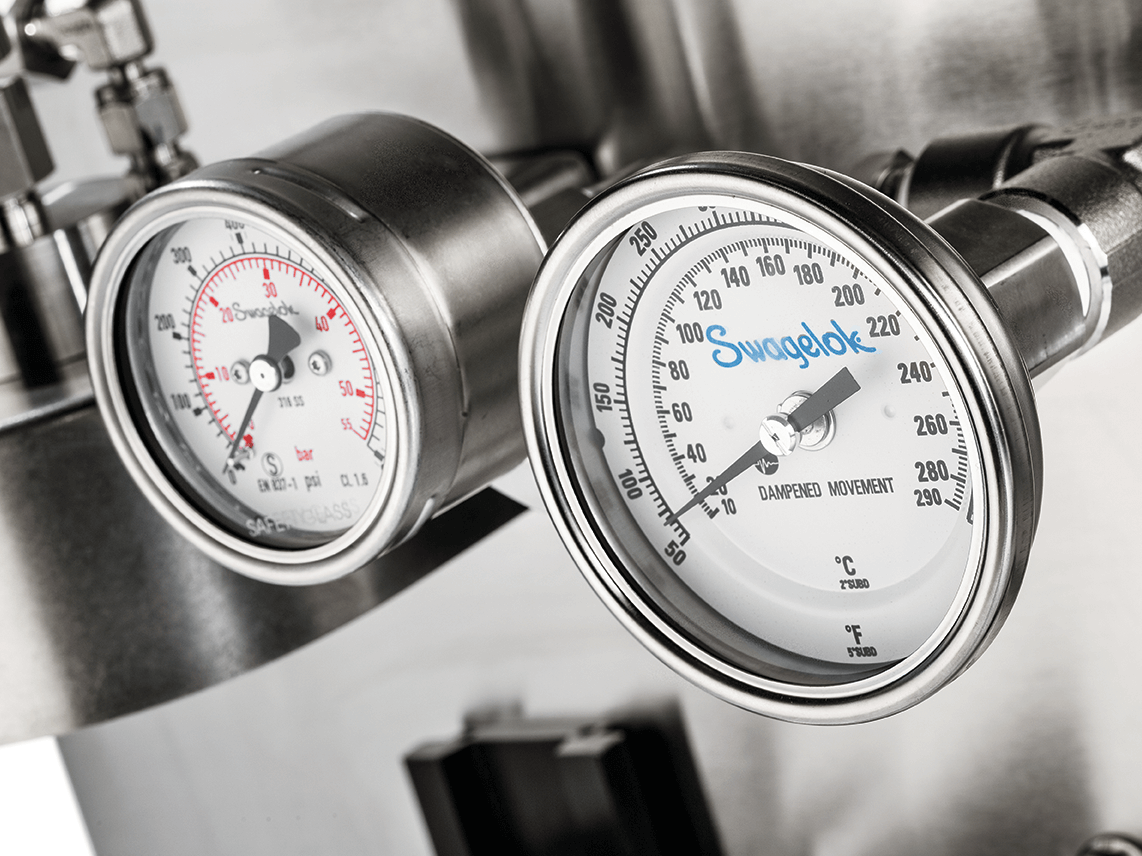

Threaded connections are some of the biggest culprits when it comes to heat transfer fluid leakage. Commonly used NPT piping is great for many fluid applications, but not for volatile fluids like PFCs. These fluids are prone to leaking through tapered pipe threads and are better contained with welded connections or continuous tubing. Swagelok’s orbital welding system, specifically designed for consistent, time- and cost-efficient welding of tubing and piping, is a great way to get in-house welding capabilities, allowing you to conveniently and inexpensively weld leak-proof connections wherever they are needed.

Pumps, seals, and connectors suitable for water are generally not adequate for fluids like Fluorinert and should be replaced with PFC-appropriate components. Your supplier can help evaluate your system and recommend fittings and connections that will prevent leakage.

Helping Fabricators and OEMs Address Thermal Management Challenges with New Technologies

Semiconductor fabricators and OEMs don’t have to face thermal management challenges alone. Swagelok’s new technologies as well as tried-and-true solutions are available to help you keep operations running at maximum efficiency.

Swagelok has the expertise, the experience, and the quality components semiconductor manufacturers and OEMs need to face thermal management challenges. We are the industry leader in gas delivery system components, including insulated tubing and fittings, and all our products are backed by Swagelok’s Limited Lifetime Warranty—the best in the industry.

Our expert Field Engineers can offer on-site or remote guidance to help you choose the right components and seamlessly incorporate them into your existing systems. Our convenient location in Northern California allows us to get our products and engineers to you right when you need them.

To find out more about how Swagelok Northern California can help tackle thermal management challenges with new technologies, contact our team today by calling 510-933-6200.

Thermal expansion is a concern in any precise manufacturing operation. Changes in temperature cause materials to expand or contract, and even slight temperature variations can cause the extremely thin films of material deposited on silicon wafers to shift. This is known as edge placement error (EPE), and it can cause chips to fail through misalignments.

Thermal expansion is a concern in any precise manufacturing operation. Changes in temperature cause materials to expand or contract, and even slight temperature variations can cause the extremely thin films of material deposited on silicon wafers to shift. This is known as edge placement error (EPE), and it can cause chips to fail through misalignments. No matter how precise your TCUs are, your thermal management system is only as good as its insulation. To minimize heat transfer between process gases and the environment, piping, tubing, hoses, and other

No matter how precise your TCUs are, your thermal management system is only as good as its insulation. To minimize heat transfer between process gases and the environment, piping, tubing, hoses, and other