2025 Local Support Line Card

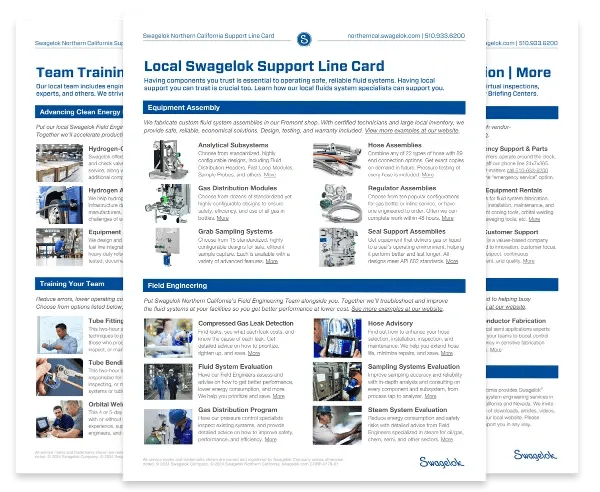

Equipment Assembly and Testing

Whether it’s attaching an adapter to a valve or configuring a complete panel or sampling system, we can design, build, and warranty your assembly here in Fremont, California. We also offer training to avoid errors.

Most-requested equipment includes:

- Gas Distribution Modules

- Grab Sample Panels

- Hoses with End Connections

- Mechanical Seal Support Assemblies

- Tube Bending and Welding

You choose the starting point:

- Customize a Swagelok design

- Provide your own design

- Request engineering to order.

Also see: Seven Ways to Reduce Equipment Assembly Risks and Costs

Efficient Plant Operations

To get better performance from your facility's fluid systems, collaborate with our Swagelok Field Engineers. They offer actionable advice to address performance issues and spot potential problems like leaks.

Popular services include:

- Fluid System Evaluation

- Gas Distribution Evaluation

- Hose Management Evaluation

- Sampling System Evaluation

- Steam System Evaluation

You receive industry-leading fluid system technical expertise and application experience. You may collaborate with our lead Field Engineer, Stacey Phillips, MEng, who has helped hundreds of Swagelok customers over 18 years.

Select from:

- Onsite visit by Swagelok Field Engineer

- Virtual visit with Swagelok Field Engineer

- Combination of onsite and virtual

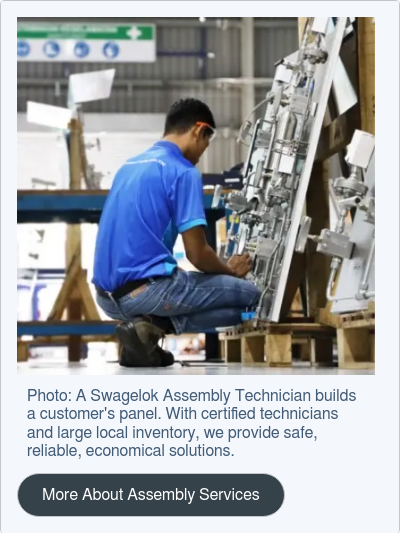

Training the Team

From under-tightening tube fittings to installing valves incorrectly or tube bending mistakes, errors lead to repairs, replacements, and rework over time. With our training, fabricators, installers, and technicians get instruction from certified experts.

Upcoming sessions include:

- Orbital Welding Training

- VCR Face Seal Fitting Installation

- Tube Fitting Installation Safety

- Tube Bending Fundamentals

- Advanced Tube Bending

Our practical, hands-on courses help new team members and industry veterans alike. Successful participants earn a Swagelok Certificate of Completion. Format options include:

- Session in our Fremont Training Center

- Group session at your facility

- Series or annual trainings

Also see: Swagelok Northern California Training and Events page

Advancing Clean Energy Projects

Get expert support whether your teams are working with compressed natural gas, liquefied natural gas, or hydrogen fuel cell applications.

Options include:

- Hydrogen Application Support

- Equipment for Hydrogen Service

- Hydrogen-Compatible Components

- Rapid Solutions Capability

- Pre-bent Small Bore Tubing

Equipment assembly examples:

- CNG Priority Panels

- Fuel Line Integrations

- Dispensing Systems

- Heavy Duty Refueling Boxes

Also see: Luxfer Hydrogen Fuel Cell Case Study

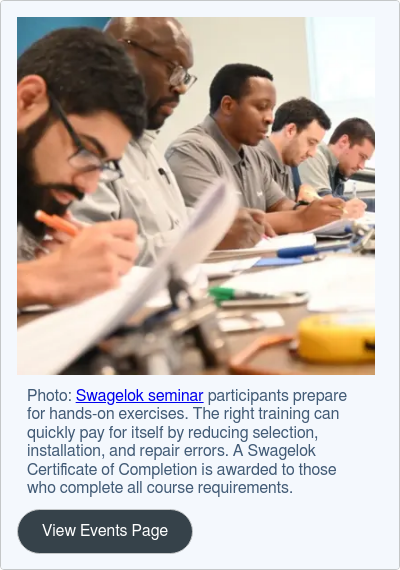

Process Fluid Sampling

It has long been speculated that sampling systems account for 80 percent of all analytical instrumentation problems. Swagelok Field Engineers can help you improve sampling system reliability with expert, in-depth analysis of every component and subsystem, from tap to analyzer.

Benefits include:

- Reducing time delay

- Improving analyzer compatibility

- Obtaining more representative samples

Starting with a meeting or phone conversation, we gather information to understand your unique challenges or goals. We want to learn about our customer's application, operations, and current challenge. Then we recommend next steps and provide a quote, if applicable.

Also see: Industrial Sampling Systems Book Excerpt

Semi Fabrication Uptime

Swagelok Northern California can help you select appropriate products for semiconductor manufacturing, provide detailed technical information and CAD models, train and assist your team in welding, engineer custom parts for new processes, and more.

- Advantage at the Source: Gain greater thermal control, prevent contamination, and promote safe containment.

- Advantage in the Gas Box: Shorten purge times, lengthen service life, and switch chemical delivery with optimal control.

- Advantage at Point of Use: Achieve precision high temperature chemical delivery, greater dosing accuracy, and cleanliness.

- Advantage at Exhaust Point: Purge excess chemistries, maintain optimum pressure, and command efficiency in the final stage of the process.

- Assemblies for Speed & Savings: Our team of certified assembly technicians can build assemblies or subassemblies using Swagelok components, as well as other system components. In one case, our engineering team turned a client's pencil sketch into four thermocouple assemblies in two weeks.

Swagelok Company received the Lam Research's Supplier Excellence Award. Gases and Instrumentation Magazine awarded Swagelok the Golden Gas for its ALD Diaphragm valve.

Also see: Swagelok ALD Valves Catalog

Work with Top Fluid Systems Engineers

Swagelok Field Engineers earn certification by completing hundreds of training hours with internationally renowned experts and passing dozens of exams. They re-certify every three years. Some earn additional certifications, such in process fluid sampling and pressure control.

For example, Stacey Phillips, MEng, has worked alongside hundreds of Swagelok customers over 18 years.

- As Swagelok Northern California Director/General Markets she helps teams effectively manage hydrogen, improve plant operations, save on equipment assembly, make process fluid sampling reliable, and keep systems running for semi fabrication.

- Previously, she served as Swagelok Field Engineering Manager/Americas. Your team can rely on her expertise in pressure control, process instrumentation and automation, valve selection, grab sampling, extending the life of rotating equipment, and more.

- Earlier, she built a thriving Swagelok Custom Solutions practice in Canada. "In the early days, I would give a quote for equipment, then go in the back and build it," she says. That meant CAD design, building enclosures, configuring instrumentation, testing—whatever was needed.

Stacey holds a Master of Engineering (MEng) from University of Colorado, Boulder and a Bachelor of Science (BSc), Biomechanics from University of Alberta.

Fast and Flexible

We provide advice when and how you need it. We can visit your facility, conduct virtual inspections, collaborate by video, exchange CAD files, and more.

Passion for Details

Could installation be simplified? Which predictive maintenance would save money? Could panels be standardized? Our team strives for total solutions.

Global Resources

Work with locals you can reach any time. Urgent issue? Call 510.933.6200 and follow "emergency service" prompts. You can reach us 24 hours a day, every day.

60 Years of Supporting Local Plants

Consistent Results

Our local team includes engineers, tech support gurus, assembly technicians, procurement experts, and more. We strive to integrate all our capabilities to deliver total solutions to you.

Certified Specialists

Our engineers earn certification by completing hundreds of training hours with internationally renowned experts and passing dozens of exams. They also recertify every three years.

Global Resources

Our local field engineers are part of a network of Swagelok field engineers around the world. They consult each other for specific applications experiences and more.

Examples

Put our team alongside yours

We are glad to provide details, pricing, and examples. Please answer a few questions so we can help you.

Quality First

Swagelok's warranty, certifications, SQS quality system, and awards demonstrate that quality is top priority. Since 1947.

Easy Start

Having a conversation with us creates no obligation. Answer some initial questions, then a member of our team follows up.

Local Team

Work with knowledgeable, enthusiastic reps. We value top talent, have low turnover, and won a Best Workplace award.

Johan LeGrand, Senior Buyer, Imtech

"Swagelok’s kitting and assembly gave us everything we needed for the sampling systems, right when we needed it. The pre-packaged kits were delivered to the door, on time. It was the ideal solution."

Tan Ha, Master Technologist, HP Labs

"In less than two weeks they came up with a whole solution. And in the last five years I have had no more leaks in the system. That's the sort of capability that Swagelok provides, and no one else can."

Marcos Porto, Specialty Gases Manager, Praxair

"Swagelok is basically an industry standard. It's rated by our customers as the best solution that we can provide."

Innovative solutions

"Swagelok has worked with me and my engineers very closely on two critical development projects - providing prototype parts in a timely fashion as well as providing innovative solutions."

.webp?width=210&height=70&name=StickyLogo%20(5).webp)

.webp?width=600&height=338&name=CUSTOMERS%20(10).webp)

.webp?width=600&height=338&name=CUSTOMERS%20(8).webp)

.webp?width=600&height=338&name=CUSTOMERS%20(9).webp)