Swagelok Valves at a Glance

A valve’s function (on/off or flow control), nature of fluid (liquid or gas), and direction of flow (unidirectional or bidirectional) determine the type of valve required for a system. Swagelok offers both on-off valves and flow control valves.

On-Off Valves

These valves are ideal for simple on-off operations. Depending on your need, the following valves are useful to control on-off operations:

These valves are ideal for simple on-off operations. Depending on your need, the following valves are useful to control on-off operations:

- Ball Valve: practical and economical; ideal for straight flow path control with just a quarter-turn of the handle or actuator

- Gate Valve: for large processing; used to control flow larger than two inches by raising/dropping the gate through a handle

- Diaphragm Valve: for ultra purity applications; used to achieve precise actuation speeds and first shut-offs through the bi-directional pressure-responsive throttle

- Bellows Valve (pictured above): for high containment zones; used to offer a strong, welded seal to the atmosphere and safeguard against leakage

Flow-Control Valves

Flow control valves are useful when you need to achieve a specific flow rate using the valve.

Flow control valves are useful when you need to achieve a specific flow rate using the valve.

The most common flow valves are:

- Needle Valve: for lighter, less viscous fluid; controls fluid flow with a tapered pin moving up and down through a handwheel

- Fine Metering Valve: for precision flow control; the long, fine stem is ideal for high flow, high press requirements

- Quarter-Turn Valve (pictured above): for economical low throttling applications; uses a ball valve design that rotates a cylindrical plug by a quarter to block the flow path

- Rising Plug Valve: for handling slurries or solid impurities; reduces flow as a tapered plug lowers into an orifice

The Benefits of Swagelok High-Temperature Valves

The biggest advantage to using Swagelok high-temperature valves is that they are easy to service and rebuild with Swagelok exclusive kits. These kits give you clear instructions on how to adjust or replace the packing along with how to rebuild the assembly, if necessary.

Servicing needs may vary from one valve to another. However, it’s very simple to adjust the packing through the upper nut of the valve. If you need to completely rebuild the assembly, it’s imperative to gain access to the interior of the valve.

With Swagelok valves, you can gain access either by simply removing the top nut or by completely removing the upper works from the body. Swagelok metering valves make use of O-rings instead of packing. They may need to be serviced after being in the application for a long period of time.

With the prepackaged kits, your team is able to do its job faster while being meticulous about quality. Because of the way Swagelok parts and assemblies are produced, Swagelok stands behind each of its parts and each of its assemblies with an industry-leading Limited-Lifetime Warranty.

You can easily get access to Swagelok kits and service instructions through the Swagelok exclusive Electronics Desktop Guide (Swagelok eDTR), available for download here.

Swagelok 60 Series High-Temperature Valves

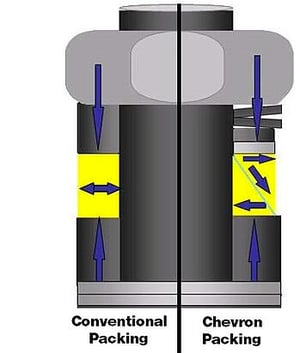

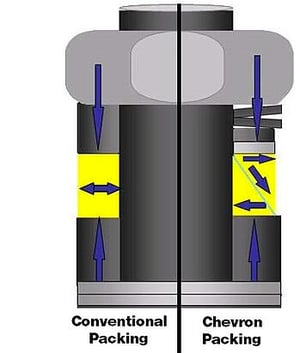

Swagelok 60 Series high-temperature valve design combines reinforced PTFE with a coned-disc spring-loaded seat to compensate for seat wear and pressure and temperature changes. A two-piece chevron packing is used to ensure a reliable stem seal. That way, more of the torque on the packing nut can be distributed to the contact area with the stem and the body of the valve. The packing is backed up by a pair of Belleville springs to apply a consistent load on the packing.

Swagelok 60 Series high-temperature valve design combines reinforced PTFE with a coned-disc spring-loaded seat to compensate for seat wear and pressure and temperature changes. A two-piece chevron packing is used to ensure a reliable stem seal. That way, more of the torque on the packing nut can be distributed to the contact area with the stem and the body of the valve. The packing is backed up by a pair of Belleville springs to apply a consistent load on the packing.

Unique Features

- Smooth, quarter-turn rotary operation

- Customized body and seat materials

- End connections range from ⅛ inch to 2 inch

- Optional pneumatic and electric actuators

- Vented balls to prevent overpressurization

- API 641 certified for low fugitive emissions

Customize Assembly for High-Temp Applications

When you are looking for a 60 Series ball valve for high-temperature service, a quick look at the pressure-temperature chart in our catalog will show you that the Thermal Service version has the highest temperature rating. What some often miss is that it uses metal-to-metal seats. Metal simply can't seal as well as elastomer seats. It's important to look at the seat leakage rate for the valve.

Different parts of the valve can be customized using a wide variety of materials to accommodate your system temperature needs. With alternative materials of construction, the valves can be configured for a wide temperature range; from as low as 68.9 bar at -28°C with Alloy X-750 seats to as high as 55.1 bar at 232°C with PEEK seats.

The customization options for Swagelok 60 Series valves include:

For On-Off (two-way) Valves

- Valve Body Material: 316 stainless steel, brass, or carbon steel

- Seat Material: Reinforced PTFE, Alloy X-750, carbon/glass PTFE, PEEK, UHMWPE, or virgin PTFE

- Flange Seal Material: Alloy X-750, PTFE coated, ethylene propylene, neoprene, PTFE

For Switching (three-way) Valves

- Seat Material: Reinforced PTFE, carbon/glass PTFE, PEEK, UHMWPE, or virgin PTFE

Special Application 60 Series Valves

In addition to the general-purpose 60 Series ball valves, Swagelok offers these variations for special applications:

- S60P Series: Steam series ball valves for erosive nature steam

- T60M Series: Thermal service ball valve for hot gasses or low viscosity fluids

- A60T Series: Fire series valves to offer reliable stem seal in the event of fire

- C60V Series: Valves for chlorine service

- W60T Series: All-welded valves for leak-tight fluid containment

- L60 Series: Valves for low-temperature service (–53 to 121°C)

- R60T Series: Valves for rapid cycling service or for applications where packing adjustment is difficult

With so many options, it can be easy to become overwhelmed. Swagelok can help.

Don’t Let Selecting High-Temperature Valves Overwhelm You

Swagelok Field Engineers can help you select and size valves for your instrumentation system. They will analyze your system flow to suggest matching valve types and associated auxiliaries for smooth fluid management. Our experienced Field Engineers can also help you customize different parts of your valve, such as O-ring, seat, handle, body, and bonnet with available material options to meet your system’s temperature and pressure rating.

To find out more about how Swagelok Northern California can help you with selecting high-temperature valves for your application, contact our team today by calling 510-933-6200.

These valves are ideal for simple on-off operations. Depending on your need, the following valves are useful to control on-off operations:

These valves are ideal for simple on-off operations. Depending on your need, the following valves are useful to control on-off operations: Flow control valves are useful when you need to achieve a specific flow rate using the valve.

Flow control valves are useful when you need to achieve a specific flow rate using the valve.  Swagelok 60 Series high-temperature valve design combines reinforced PTFE with a coned-disc spring-loaded seat to compensate for seat wear and pressure and temperature changes. A two-piece chevron packing is used to ensure a reliable stem seal. That way, more of the torque on the packing nut can be distributed to the contact area with the stem and the body of the valve. The packing is backed up by a pair of Belleville springs to apply a consistent load on the packing.

Swagelok 60 Series high-temperature valve design combines reinforced PTFE with a coned-disc spring-loaded seat to compensate for seat wear and pressure and temperature changes. A two-piece chevron packing is used to ensure a reliable stem seal. That way, more of the torque on the packing nut can be distributed to the contact area with the stem and the body of the valve. The packing is backed up by a pair of Belleville springs to apply a consistent load on the packing.