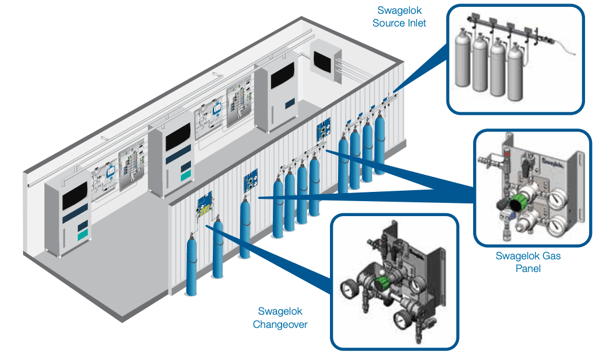

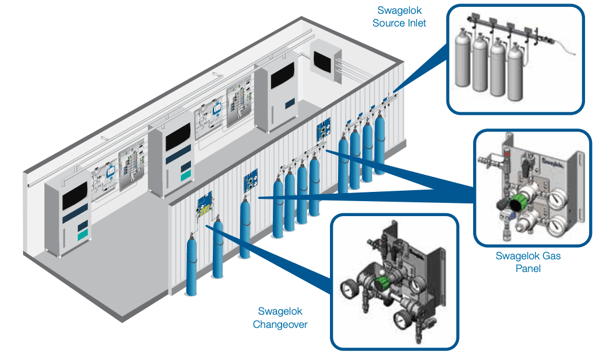

Gas distribution systems serve a crucial role in many petrochemical, semiconductor, research and development, and biotechnology facilities in Northern California and are responsible for safely, effectively, and reliably delivering pressurized gas from the high-pressure source to the point-of-use at a specified pressure and flow rate. To achieve this, gas distribution systems are commonly comprised of four subsystems:

- A source inlet connection with collection cylinders

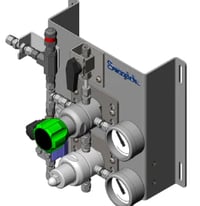

- A gas control panel (primary gas pressure control)

- A point-of-use

- An automatic changeover

Reliable operations of gas distribution systems depend strongly on gas panels, as they are the primary gas pressure control point and must achieve the bulk of pressure management and reduction of the source gas. Working with an industry-leading gas panel design manufacturer can help ensure safe and reliable operations through high-quality, customizable gas panel designs. Whether looking to standardize gas control panels across a facility—or looking to improve operations through updated equipment, there are a number of things to keep in mind when searching for a gas panel design manufacturer in Northern California.

What to Look for in Gas Panel Design Manufacturers

When searching for the ideal gas panel design manufacturer, it is important to look for one who has strong application experience and knowledge, can customize panel designs to best suit application and process needs, has a local presence with timely onsite assistance, and focuses on quality. Let’s take a deeper look into these aspects.

Strong Application Experience and Knowledge

Gas panel design manufacturers who have strong experience and knowledge in a wide variety of specific Northern California gas distribution applications are likely to provide the highest level of insight into choosing proper configurations, components, and materials of construction. Gas panel design manufacturers should design gas panels with industry best practices in mind while also understanding the needs and challenges of industry-specific challenges to further improve panel designs.

Customizable Gas Panel Design Options

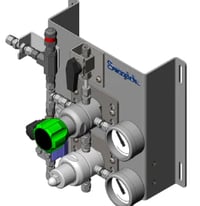

Custom gas panel designs are invaluable to many industrial applications, particularly in the Bay Area. Many facilities in this area face operational and maintainability challenges with outdated equipment or variations in gas distribution equipment across facilities. Other facilities struggle with limited space and restrictions surrounding system layouts. Manufacturers that can customize gas panel designs and layouts can often accommodate such restrictions through modular, optimized gas panels.

equipment across facilities. Other facilities struggle with limited space and restrictions surrounding system layouts. Manufacturers that can customize gas panel designs and layouts can often accommodate such restrictions through modular, optimized gas panels.

Custom-configured panel designs not only allow for the flexibility to meet challenging application- or industry-specific requirements through optimized designs, but they can also alleviate common operational and maintainability issues. Panel designs should reduce the risk of operator error by featuring intuitive, clearly labeled components, especially for critical components such as pressure regulators and pressure valves.

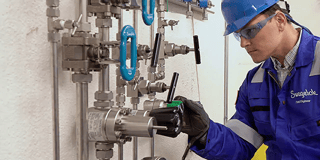

Maintainability concerns can be addressed with modular designs which allow maintenance technicians to remove or replace components without needing to disassemble the entire panel. Some manufacturers will utilize tube fittings in gas panel designs to enable ease of maintenance through the ability to leave the entire panel in place while performing scheduled maintenance.

Local Presence and Timely Onsite Assistance

The need for manufacturers with a strong local presence and timely onsite assistance cannot be emphasized enough. Whether needing quick access to components in a pinch or needing an expert opinion onsite to troubleshoot mission- critical gas distribution problems, this is a crucial aspect to look for in gas panel design manufacturers. Manufacturers with extensive local inventories can provide quick and easy access to components and equipment to minimize costly downtime. Onsite field engineering services, such as system audits, leak troubleshooting, and design advice, can greatly benefit Northern California facilities.

critical gas distribution problems, this is a crucial aspect to look for in gas panel design manufacturers. Manufacturers with extensive local inventories can provide quick and easy access to components and equipment to minimize costly downtime. Onsite field engineering services, such as system audits, leak troubleshooting, and design advice, can greatly benefit Northern California facilities.

Quality Control and Quality Assurance

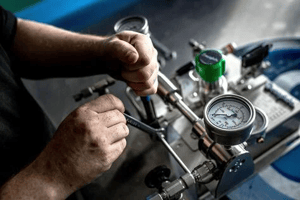

High-quality components, materials, and equipment are essential for reliable gas distribution operations. When looking at gas panel design manufacturers, it is critical that they focus heavily on quality as a core value. Manufacturers should have a well-established quality management system in place with proper quality control and quality assurance procedures in place to ensure consistent quality across each and every product. Manufacturers should:

- Test raw materials to ensure purity and quality of materials for long-lasting components.

- Manage quality along the entirety of the supply chain to guarantee consistency across all parts and components.

- Incorporate a quality-oriented culture throughout the company while focusing on continuous improvement.

- Have full confidence in the quality of their products and offer warranties on their products.

Choose Gas Panel Design Manufacturers Who Design for Safety and Reliability

Safe and reliable operations are a requirement for any gas distribution system. Working with a manufacturer that designs gas panels that promote safety and reliability can greatly reduce the risk of safety risks and help ensure gas panels operate effectively with an extended life cycle.

Design to Promote Operator and Environmental Safety

When working with gases that may be toxic or otherwise harmful to operators and/or the environment in the event of leakage, it is important that gas panels, and all other subsystems, are designed to prevent and mitigate safety risks.

In such applications, manufacturers should suggest solutions, such as implementing restricted flow orifices near the gas source and using compression fittings in place of threaded fittings, to provide an added level of safety for facility employees and the environment.

Critical gas pressure control components, such as pressure regulators and relief valves, must be sized appropriately for specific applications, flow rates, and pressures in order to ensure the safe regulation of gas pressure. Gas panel design manufacturers should be highly knowledgeable on the selection and sizing of gas pressure control equipment. The selection between single-stage and dual-stage as well as the sizing of pressure regulators depends on the flow rate and pressure required for an application. The proper calculation of flow rate and pressure is crucial for safe pressure regulator and gas panel functionality. It depends on the gas type as well as several application-specific process aspects. Ideally, gas panel design manufacturers should have experienced fluid systems engineers who can assist with this calculation to ensure the sizing is suitable for all expected ranges of pressure and flow rate.

the sizing of pressure regulators depends on the flow rate and pressure required for an application. The proper calculation of flow rate and pressure is crucial for safe pressure regulator and gas panel functionality. It depends on the gas type as well as several application-specific process aspects. Ideally, gas panel design manufacturers should have experienced fluid systems engineers who can assist with this calculation to ensure the sizing is suitable for all expected ranges of pressure and flow rate.

Design to Promote Long-Term Reliability

As the primary pressure control system, gas panel reliability is pivotal for well-performing gas distribution systems. Unreliable gas panels can impact equipment, processes, and laboratories that depend on gas distribution systems to deliver gases at the correct pressure and flow rate. The result can be damaged equipment and consequently unplanned maintenance, downtime, and lost profit.

Swagelok Northern California: An Industry-Leading Gas Panel Design Manufacturer

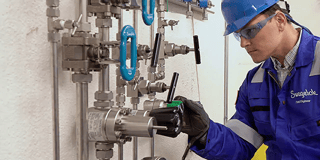

Since 1947, Swagelok has focused on designing and manufacturing the highest quality fluid systems products. Our gas panels are no exception. We have deep application experience and expertise for gas distribution systems in Northern California facilities and can help ensure safe and reliable operations. Our Field Engineers can perform an onsite analysis of your process to gain a detailed understanding of your requirements and provide customized gas panel design solutions tailored to your needs. They can also assess and troubleshoot existing panels to suggest methods to improve performance and reduce operating and maintenance costs.

of your process to gain a detailed understanding of your requirements and provide customized gas panel design solutions tailored to your needs. They can also assess and troubleshoot existing panels to suggest methods to improve performance and reduce operating and maintenance costs.

Our gas panels feature minimized threaded connections to reduce the likelihood of costly leaks and are designed for safe and simple installation, operation, and maintenance. Our gas panels are delivered to you fully assembled and tested and are backed by the Swagelok Limited Lifetime Warranty.

To find out more about the Bay Area's leading gas panel design manufacturer, Swagelok Northern California, contact our team today by calling 510-933-6200.

equipment across facilities. Other facilities struggle with limited space and restrictions surrounding system layouts. Manufacturers that can

equipment across facilities. Other facilities struggle with limited space and restrictions surrounding system layouts. Manufacturers that can  critical gas distribution problems, this is a crucial aspect to look for in gas panel design manufacturers. Manufacturers with extensive local inventories can provide quick and easy access to components and equipment to minimize costly downtime. Onsite field engineering services, such as system audits, leak troubleshooting, and design advice, can greatly benefit Northern California facilities.

critical gas distribution problems, this is a crucial aspect to look for in gas panel design manufacturers. Manufacturers with extensive local inventories can provide quick and easy access to components and equipment to minimize costly downtime. Onsite field engineering services, such as system audits, leak troubleshooting, and design advice, can greatly benefit Northern California facilities.

the sizing of pressure regulators depends on the flow rate and pressure required for an application. The proper calculation of flow rate and pressure is crucial for safe pressure regulator and gas panel functionality. It depends on the gas type as well as several application-specific process aspects. Ideally, gas panel design manufacturers should have experienced fluid systems engineers who can assist with this calculation to ensure the sizing is suitable for all expected ranges of pressure and flow rate.

the sizing of pressure regulators depends on the flow rate and pressure required for an application. The proper calculation of flow rate and pressure is crucial for safe pressure regulator and gas panel functionality. It depends on the gas type as well as several application-specific process aspects. Ideally, gas panel design manufacturers should have experienced fluid systems engineers who can assist with this calculation to ensure the sizing is suitable for all expected ranges of pressure and flow rate. of your process to

of your process to