Analytical Subsystems

Locally Built Analytical Subsystems

Swagelok engineers have developed standardized yet highly configurable designs for assemblies that meet common analytical instrumentation needs in facilities where fluids are processed. Swagelok Northern California provides design and assembly to meet a customer's exact needs. Assemblies are tested in house, delivered with documentation, and backed by Swagelok's industry-leading warranty.

Please use the button to start a job or get details, or call 510-933-6200.

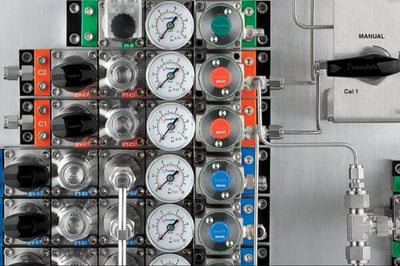

Calibration & Switching Modules

Provides a discrete switch between process samples and conditions and selects process streams for analysis. Ensures inserted samples are at the correct pressure, temperature, flow, and filtration.

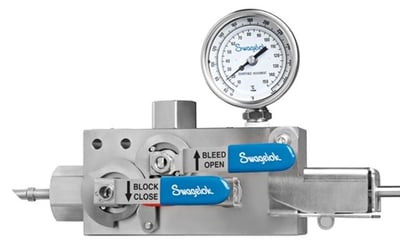

Fast Loop Modules

Handles high flows and long transport lines from tap to analyzer, reducing time delays. Minimizes pressure drop for fastest response time. Mounts directly to process nozzles and is highly configurable.

Field Station Modules

Reduces process gas pressure before transporting. Transporting a gas sample at low pressure means faster analyzer response time, less condensation, and a safer environment.

Fluid Distribution Headers

Used as versatile manifolds in gas and liquid applications. Provides a flow path with multiple outlets, similar to a large branch fitting. Inlet on one end, drain on the other, and multiple outlets.

Sample Probe Modules

Measures concentration of key components in gas/liquid streams to maintain precise process control. Used with sample probe valves, they can improve safety, sample purity, and timeliness.

Benefits of collaborating on analytical subsystems

Swagelok pre-engineered subsystems help you get in place fully documented fluid sampling and control systems and support consistency in your operations. Easy to install and operate, these subsystems offer the high quality and support you expect from Swagelok.

Reduce time delay

Simplify design

Rich documentation

What to expect

Every collaboration is a little different, but here is how a project typically progresses:

1. Design

Starting with a phone conversation or meeting, we listen to understand your application, goals, and challenges. Topics might include pressures, temperatures, dimensional requirements, presence of hazardous or flammable materials, and operator/maintenance access. We offer options and a quote. This is a collaborative process.

2. Fabrication

After design approval, certified technicians handle fabrication, working in our Class 100 clean room if necessary. Swagelok assembly certification involves producing numerous complete assemblies, each of which is inspected by Swagelok manufacturing engineers and put through destructive testing. Passing requires a 100% score on every exam.

3. Quality Control

Every assembly is pressure tested with water to ensure proper assembly and high performance. In addition to standard testing, we can do helium leak testing, hydrostatic testing, nitrogen pressure testing, and pressure decay testing. The rigorous assembly process and 100% testing ensures you receive a high-quality reliable assembly.

4. Delivery

We clean and either cap or bag the assembly to ensure contaminants are not introduced into your fluid system from the assembly. A test certificate is packaged with each assembly. Orders ship daily or can be picked up in Concord, Sunnyvale, or Fremont. Assemblies can be installed immediately. Give us a call if you need advice on installation.

From simple to complex, Swagelok Northern California has the skills, tools and components to design, build, and test assemblies that exactly meet your needs. Our dedicated Custom Solutions team includes Swagelok-certified mechanical engineers, welders, and assembly technicians — many with decades of experience. We produce a professional, repeatable solution, with testing, inspection, and packaging included—all covered by Swagelok’s Limited Lifetime Warranty.

We stand behind every assembly

Every Swagelok product, assembly, and solution comes with Swagelok's Limited Lifetime Warranty. Systems use Swagelok components, which are designed and manufactured to the highest quality standards. Per our documented quality process, fabrication is handled by Swagelok-certified associates. Swagelok assembly certification requires that every sample produced earns a grade of 100% from the Swagelok manufacturing engineers who inspect it and put it through destructive testing.

Swagelok Northern California is always reachable. Urgent need? Call 510-933-6200 and listen for "emergency service". This option is staffed around the clock, 24x7, every day of the year.

-1-1.png?width=350&height=350&name=ValuesWheel-Flat_2023_LG%20(1)-1-1.png)

About Swagelok Northern California

Since 1963, Swagelok Northern California has provided thousands of manufacturers, processors, suppliers, and innovators with Swagelok fluid system products and expertise. Over 100 engineers, technicians, trainers, and other professionals make up our local team. With that expertise and $25M worth of Swagelok products in our three local warehouses, we are ready to help you run safe, cost-effective operations.

About Swagelok Company

Established in 1947, Swagelok Company is a global company headquartered in Solon, Ohio. It has 20 manufacturing facilities, 6 global technical centers, and a network of 225 sales and service centers in 70 countries employing thousands of associates.

Request Information/Support

Need details or a quote? We are ready to help.

.webp?width=210&height=70&name=StickyLogo%20(5).webp)

.jpg?width=600&height=338&name=Thumb_vid_ProcessAnalyzerSamplingChallenges%20(1).jpg)