Fluid System Design

Designing Streamlined Fluid Systems

When one of our customers has an unnecessarily complex design for an assembly, they are likely to buy more components than necessary, put more work into assembly, have to install a bigger assembly, and deal with more connection points for years to come.

Swagelok engineers have a proven method for designing streamlined fluid systems. A video below shows an example. Please use the button get in touch for details or a quote. (In a hurry? Please call 510-933-6200.)

Benefits of collaborating on fluid system design

Compared to entirely DIY fluid system design, collaborating with Swagelok Northern California has benefits:

Quality

Speed

Save on components

Save on maintenance

Dimensions

Local support

What to expect

Collaboration to produce a streamlined fluid system design generally progresses like this:

1. Needs analysis

Share a scribble on the back of a napkin (we have received these by fax!) or CADs with detailed design. We can start from scratch or at any stage. Short deadline? Tight space? Budget pressure? We make sure we fully understand your needs before starting the process to streamline a design.

2. Design (collaborative)

Swagelok may have a standardized design we can configure to exactly meet needs. This can save our customer quite a bit of time and money. Either way, we can work in your files or provide new sales drawings or CAD drawings (2D and/or 3D) with detailed technical quotations. Then we can iterate.

3. Options

You can run with your plan for a reasonable NRE fee, or request a quote on having our team handle assembly. If you want us to build, our certified technicians pull from our onsite warehouse, fabricate, and test. You receive a fully built, leak-tight, documented assembly ready to install.

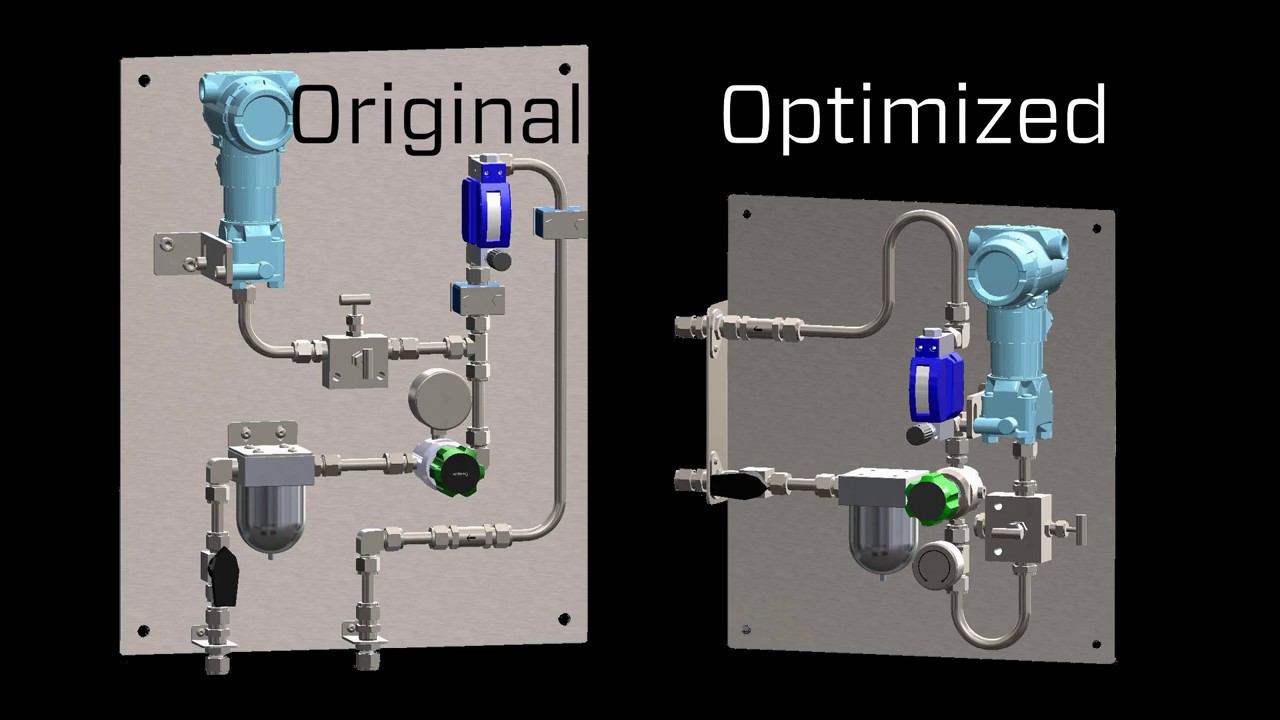

Optimizing can yield substantial savings

Our fluid system engineers have simplified thousands of fluid system assemblies, and we are ready to help you too. The first video below shows an example ("Original vs Optimized") of immediate savings achieved by optimizing a design. The optimized version of this customer's panel has 20% fewer connections, uses 39% fewer parts, costs $400 less per panel, and is smaller than the original.

About Swagelok Northern California

Swagelok Northern California provides Swagelok fluid system products, assemblies, and services to California and Nevada companies. Our fluid system engineers, trainers, support specialists, and technicians are devoted to helping busy customers run safe, efficient operations. We have tens of thousands of Swagelok tube fittings, valves, hoses, regulators, tubing, and other types of parts in stock in our local warehouses. Give us a call at 510-933-6200.

Request Information/Support

Need details or a quote? We are ready to help.

.webp?width=210&height=70&name=StickyLogo%20(5).webp)