There are many auto changeover manifold options—Swagelok can help choose the best one for your needs.

An auto changeover manifold delivers gas to a system without interrupting the flow of gas. Most auto changeovers utilize two stages to reduce pressure that ultimately results in constant outlet pressure. This is beneficial for many systems that require a continuous supply of gas or else would have processing delays or failures.

Auto changeover manifolds are also important for systems where stopping the flow of gas to replace empty cylinders would cause operations to be costly or inefficient. As such, an auto changeover manifold is an important component in many operations for cost, efficiency, and overall production.

The choice of an auto changeover manifold is dependent on the application and conditions of operations. In this guide, we will examine the conditions best suited for several different auto changeover manifold options.

Operational Needs of an Auto Changeover Manifold

When choosing an auto changeover manifold, there are several aspects to consider. Auto changeover manifolds can be autonomous or semi-autonomous, and this distinction can have significant ramifications for operations. The gas substance being used will also have a significant influence on the auto changeover manifold being used.

Autonomy and the Auto Changeover Manifold

Two options to consider for operations with a gas changeover manifold include semi-automatic and automatic. The semi-automatic option utilizes the pressure differential to initially switch but then requires an operator to switch back. The autonomic changeover manifold senses the pressure differential and then automatically switches back and forth. Though the autonomic changeover manifold requires less human observation, there are more components—sensors and computer automation—which will require additional upkeep.

Both systems are potentially beneficial depending on the scale of operation and the responsibilities of those involved in maintaining efficient operations. Typically, the larger the scale of operation, the more likely a completely automatic changeover will be beneficial. Though initially, the costs of a fully automatic changeover panel are higher, the benefit of allocating human resources elsewhere often offsets costs in the long term.

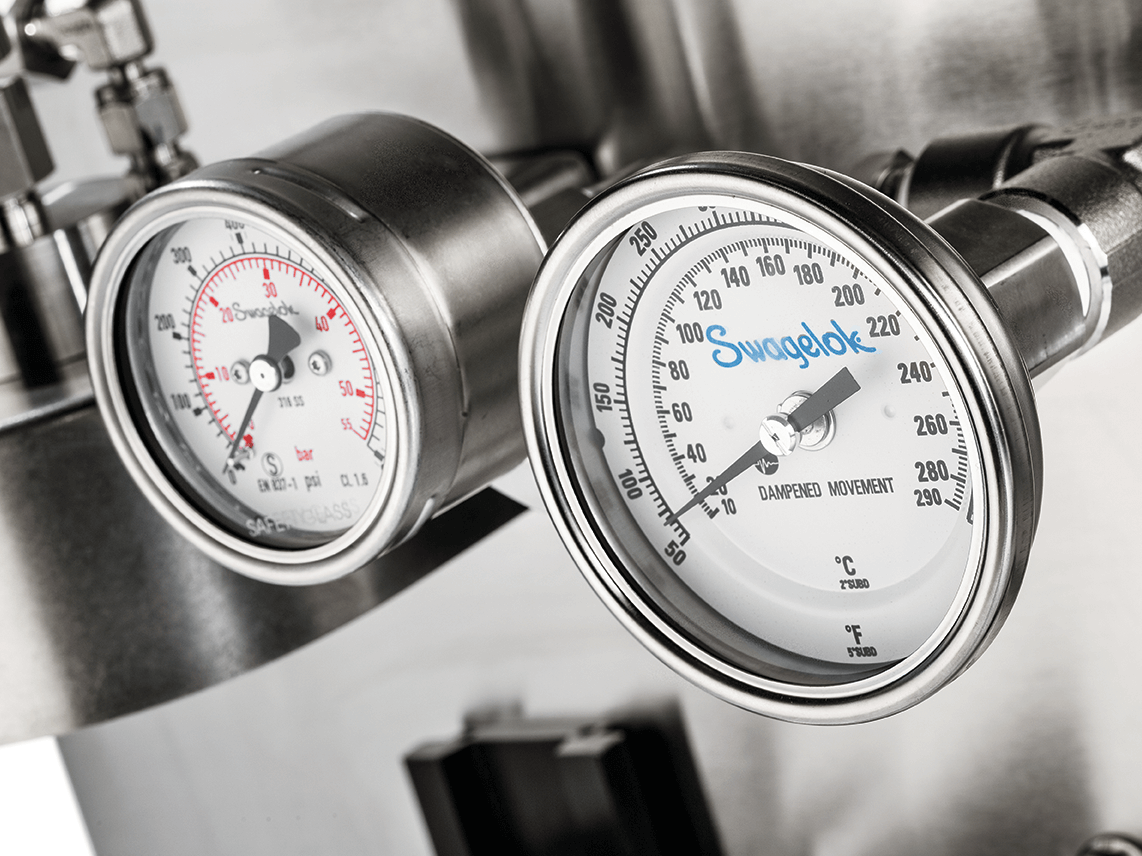

Another consideration for the changeover manifold is the gases used in operation. These gasses could react differently—and potentially be corrosive—depending on the material used in the auto changeover manifold. Further, the pressure and temperature throughout the system will be related to the gasses used in operation and, as such, are an important consideration for any component including the auto changeover manifold itself.

Gas Sources and the Auto Changeover Manifold

The gas source of the auto changeover manifold is an important consideration because it is related to pressure and temperature in the system as well as the frequency of needing to replace cylinders. The gas for the changeover manifold also needs to work well with the material of the changeover manifold. In these regards—pressure, temperature, frequency of replacing cylinders, and interaction with materials of the manifold—there are several different options in gases. These include nitrogen, helium, liquefied gas (e.g. carbon dioxide), and cryogenic containers of substances (e.g. argon). For each of these substances, it is important to consider the frequency at which cylinders need to be replaced as this will require human capital and additional costs. Before deciding on the type of substance to be used, the gas flow rate and usage time should be calculated to determine this frequency of needing to replace cylinders.

Common Designs of Changeover Manifolds and Their Benefits

High-Purity Primary Changeover Systems

High purity changeover manifolds provide a continuous flow of gases. These models typically incorporate two diffusion-resistant regulators. These models allow for the changeover system to be completely isolated. These are often found in a range of materials including brass and stainless steel to allow many types of substances to be used in operations. Delivery pressure can also be highly regulated by utilizing a built-in line regulator.

High-Flow Primary Changeover Systems

These changeover systems provide an uninterrupted high flow of gas. Often, these are used in blanketing or filling vessels.

Electronic Changeover Systems

Electronic changeover systems provide a fully automatic changeover when one of the cylinders becomes depleted. The sensors and circuits on an electronic changeover system provide the means to indicate when a changeover is needed to ensure a continuous gas supply. These systems can also use displays to allow for quick viewing of system operations.

Liquid Changeover Systems

Liquid changeover systems are used for administering vaporized gas from cryogenic containers. They allow for more options of substances to be used in operation and create fewer issues of gas depletion in a system.

Choosing the Best Auto Changeover Manifold for Gas

A changeover manifold needs to be selected based on operation processes including the type of gas and the pressure and temperature likely to be reached. Further, the level of automation (e.g. frequency of replacing cylinders) also needs to be considered. In this regard, it is best to speak with an expert on changeover design manifolds to determine the design that best fits your operational needs.

Whether you need a standard solution or custom arrangement, Swagelok can design and assemble a gas delivery system that is right for you. For example, the Swagelok Changeover (SCO). It is an automatic changeover system that seamlessly switches from one gas source to another to ensure an uninterrupted supply. This is accomplished through staggered set points of two pressure regulators, allowing the system to continue to operate as the primary gas source is changed. This changeover station allows for custom changeover set points to help reduce wasted gas left in cylinders. The benefits of using this system include:

- The changeover point remains constant.

- An optional line regulation is available if your system incorporates a point-of-use regulator downstream, eliminating the additional cost of a regulator on the SCO.

- There is a tied changeover handle design, enabling a wide range of changeover pressures to be set to your specifications.

- The system has easy serviceability, minimizing downtime if maintenance is needed.

Swagelok has been serving the needs of Bay Area refineries for more than 50 years. Our team of Field Engineers can help evaluate existing systems, select the most effective components for new systems, and develop specific equipment management programs based on the needs of your facility. And, our auto changeover manifold designs are backed by our Lifetime Warranty.

To find out more about how Swagelok Northern California can help you with your changeover design manifold needs, contact our team today by calling 510-933-6200.