Current trends in semiconductor manufacturing point to the need for fabricators to have the supply to meet increased demand. To meet this demand, it’s important that semiconductor manufacturing equipment be designed with quality and integrity and supplied in a timely manner.

By partnering with a local vendor, such as Swagelok Northern California, semiconductor manufacturers in the Bay Area, and surrounding areas, have quick access to quality components and expert consultation for seamless integration and support, every step of the way.

Supporting Silicon Valley innovation for 50+ years

From our headquarters in Fremont, Swagelok Northern California has supported semi innovators for decades. Swagelok itself has advanced semi innovation with ALD diaphragm valves tested to 100 million cycles, springless diaphragm valves, fluoropolymer valves, and more. Get in touch to discuss your project.

Get the Swagelok Advantage

At the source, gain greater thermal control, prevent contamination, and promote safe containment. In the gas box, shorten purge times, lengthen service life, and switch chemical delivery with optimal control. At the point of use, achieve precision high-temperature chemical delivery, greater dosing accuracy, and cleanliness. And at the exhaust, purge excess chemistries, maintain optimum pressure, and command efficiency.

Swagelok Quality at Silicon Valley Speed

We help engineer parts for new processes, prototype ideas, provide technical information and CAD models, lead weld training, and more. In one case, our engineering team turned a client's pencil sketch into four thermocouple assemblies in two weeks!

Swagelok Innovates in Semi Industry

Swagelok innovations include ALD diaphragm valves tested to 100 million cycles, DE series springless diaphragm valves, DRP series fluoropolymer valves, benchmark-setting Swagelok VCR, and Micro-Fit fittings and photovoltaic components for PV processing.

Swagelok Provides Quality Semiconductor Manufacturing Equipment Design and Fabrication

Swagelok provides high-quality systems and components for semiconductor manufacturing. These components include gas distribution systems and panels, cylinders, tubing, and tube fitting, and valves. With the help of a Swagelok expert, these components can be seamlessly integrated into your existing production infrastructure.

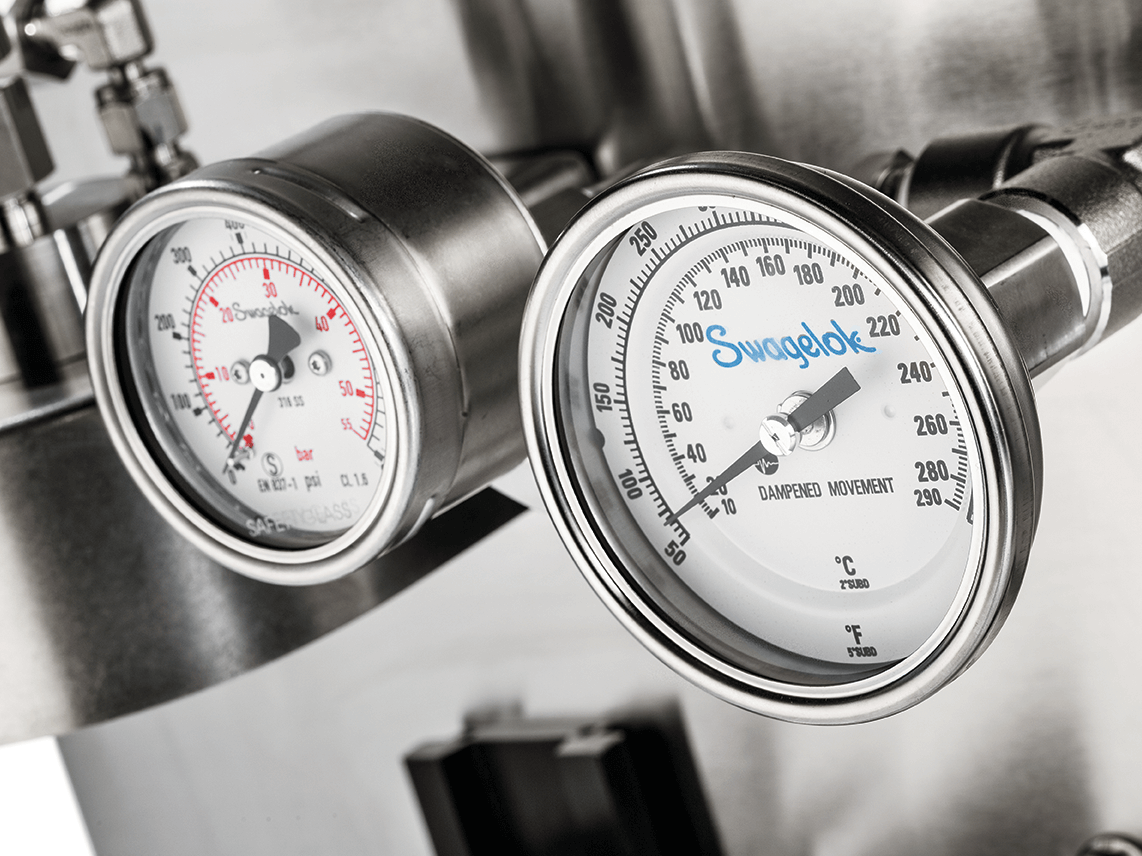

Gas Systems and Gas Panels

Swagelok offers gas systems and panels to work with your existing semiconductor manufacturing equipment. These gas systems can allow for a continuous or discrete gas flow. If needed, the gas system can allow for cylinders to be replaced without halting production. The gas panels will monitor gas for pressure, temperature, and will alert operators to potential issues of leaks.

Ancillary Components: Valves, Tubing, and Cylinders

Not only does Swagelok offer gas panels and systems, but we also provide high-quality ancillary components. These components can be used with existing gas systems or can be used to replace damaged or deteriorating components. Swagelok valves can be used to switch between cylinders (when cylinders are empty of gas) or to shut off gas flow. Tubing includes additional options—such as tube fittings that can accommodate changes to temperature and movement—to prevent leaks when dealing with toxic or pollutant materials. Cylinders—which are rated for high temperature and pressure—can have an additional bypass line. These are just some of the many options to meet semiconductor manufacturing design needs with customizable options available from Swagelok.

Value Proposition for Semiconductor Industry Firms

|

Advantage at the Source

With Swagelok, gain greater thermal control, prevent contamination, and promote safe containment. See DPX and DFX Replaceable-Seat Diaphragm Valves and VCR and Micro-Fit Fittings. |

Advantage at Point of Use

With Swagelok, achieve precision high-temperature chemical delivery, greater dosing accuracy, and cleanliness. See Atomic Layer Deposition Diaphragm Valves and Thermal Immersion Diaphragm Valves, DH Series. |

|

Advantage in the Gas Box

With Swagelok, shorten purge times, lengthen service life, and switch chemical delivery with optimal control. See Springless Diaphragm Valves for Modular Gas Systems, DE Series and All-Welded Check Valves, CW Series. |

Advantage at Exhaust Point

With Swagelok, purge excess chemistries, maintain optimum pressure and command efficiency in the final stage of the process. See Flexible All-Metal Hose, FX, FM, and FJ Series, and Gaugeable Tube Fittings and Adapter Fittings. |

|

Assemblies for speed & savings

Our team of certified assembly technicians can build assemblies or subassemblies using Swagelok components, as well as other system components, to meet your design specifications. More→ |

Swagelok Innovated in the Semiconductor Industry

Swagelok has always been at the cutting edge for semiconductor manufacturing equipment design and fabrication. As technology and industry advances occur, so too does the manufacturing equipment to best complement these advances. Swagelok has designed and customized its components to best fit the ever-evolving needs of the industry (and has won awards to prove it!). A few examples of these advances are discussed below.

Award-winning Results

Swagelok Company received the Lam Research's Supplier Excellence Award. Gases and Instrumentation Magazine awarded Swagelok the Golden Gas for its ALD Diaphragm valve.

Example: Thermocouple Design & Assembly Challenge

A producer of chemicals and specialty components for the semiconductor industry was dealing with a thermocouple assembly challenge. To effectively monitor temperatures in their assembly, they needed to create a complex mount that didn’t yet exist—within a two-week window. More→

Example: Panel Assemblies and Product Selection in Semi R&D

The R&D division of a major semiconductor manufacturer was thriving but had a tight deadline to create a panel assembly for an expansion project. If they couldn’t find a solution in time to meet the deadline, the department’s expansion would be halted. Learn about the collaboration. More→

Innovative Swagelok Valves and Cambridge NanoTech

When Cambridge NanoTech Inc. first started manufacturing atomic layer deposition (ALD) systems in 2003, the company was experiencing downtime due to underperforming valves. To extend the life of Cambridge NanoTech’s ALD gas delivery assemblies, the company tried the Swagelok ALD valve—with great success.

Swagelok Customized Design Increased Valve Operation Life

Before Swagelok designed and manufactured a customizable valve, Cambridge NanoTech Inc. was replacing valves once a month. This was not only costly due to the cost of new valves but also costly in terms of production delays and labor; when replacing valves, operators had to cool systems and take everything apart. With Swagelok’s ALD valve, Cambridge NanoTech Inc is getting millions of cycles out of the valve. More→

As can be seen above, Swagelok offers customizable high-quality semiconductor manufacturing equipment design. We also provide something more valuable—the expertise and time to help semiconductor manufacturers implement their plans. Read on to learn more about how Swagelok can help.

Application Support from Industry Experts

Swagelok Northern California can help you select appropriate products for semiconductor manufacturing, provide detailed technical information and CAD models, train and assist your team in welding, engineer custom parts for new processes, and more. We are a local vendor with experts that can provide consultation to suggest customizable solutions. Upon determining equipment design solutions, our team of experts can fabricate and provide insight for seamless integration. And, our support doesn’t end there; if future issues occur, we can advise on how to troubleshoot the problem and, if need be, replace a fabricated component.

As a local vendor for Northern California semiconductor manufacturers, Swagelok can design, fabricate, and deliver semiconductor manufacturing equipment that meets their specific needs.

To find out more about how Swagelok Northern California can help you with your semiconductor manufacturing equipment design and fabrication needs, contact our team today by calling 510-933-6200.