Centrifugal pumps and their mechanical seals and seal support systems are critical components of just about every process industry in California, including chemical and petroleum, semiconductor, oil and gas, gas and water utilities, and power generation. The number of pumps in operation can range from a handful in a pumping station to hundreds throughout California refineries. The challenges in maintaining these pumps and systems increase proportionately to the variety of pumping processes in operation.

When Evaluating Mechanical Seal Support Brands, Consider This

In the quest for ever-greater efficiency and lower costs in managing operations, I’ve found that most industries try to limit the number of vendors they work with. The criteria used to determine vendors can be as simple as “we’ve been working with them for years” or a more studied approach using quantitative and qualitative factors for evaluation.

Considering the criticality of pumps, mechanical seals, and seal support systems, I advise my clients to take the analytical approach toward vendor evaluation. And rather than create a lengthy list of evaluation criteria, I recommend they start with a shortlist of important factors to consider when choosing among mechanical seal support brands currently available on the market.

Deep Industry Knowledge and Experience

Your mechanical seal support vendor should possess deep industry knowledge and experience. That comes from decades of experience in serving the mechanical seal support system design, fabrication, and support needs of your specific industry. That experience should encompass:

- Field engineering services teams with hands-on, in-the-field experience in consulting, process assessment, system design, and after-market technical support.

- Technical understanding, not only of pumps, mechanical seals, and seal support systems, but also the upstream and downstream infrastructure and operating conditions that are critical in determining the optimum seal support system design.

- The network of technical professionals who provide worldwide services to customers in your industry with similar operations. The depth and breadth of a global network of professionals help ensure you’re benefiting from knowledge gained through years of experience.

Industry experience is one of the most important factors in ensuring that the solutions your vendor is providing are carefully matched to your specific process requirements. Standing behind the best mechanical seal support brands is a team of knowledgeable and experienced technical professionals.

Quality of Parts, Components, and Assembly Processes

The quality of components that comprise your mechanical seal support systems is critical to long-term performance and reliability. Materials used to manufacture parts and components should be selected for their ability to withstand the expected range of operating conditions. Components and parts should be manufactured following recognized quality control standards.

Your mechanical seal support vendor should be able to provide you with detailed specifications for any of the parts or components used in a mechanical seal support system.

|

The real value of a mechanical seal support system comes from expertly assembling the parts and components to create the system that precisely meets the requirements of each pumping process. Vendors’ assembly practices are certified to the ISO 9001 quality management standard. |

A vendor who has confidence in the reliable performance of their products and services should be able to offer you a warranty for the parts, components, and assemblies they’re providing.

The Range of Mechanical Seal Support Systems

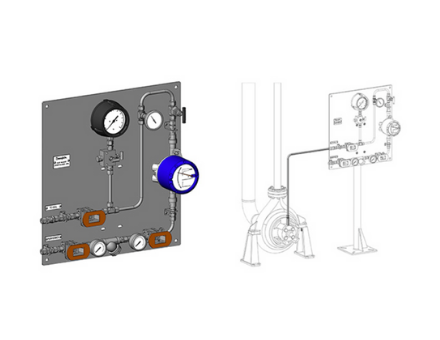

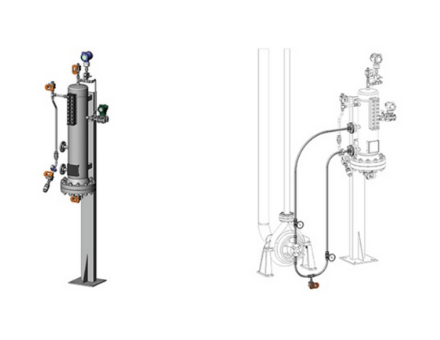

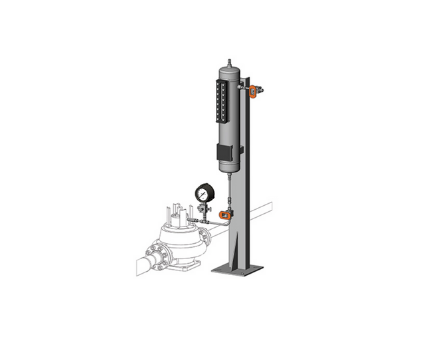

In choosing a mechanical system seal support brand, you also want to make sure they carry the range of seal support systems to match all your pumping process needs and can customize each system to maximize performance and reliability. Even though you may currently have a limited number of pumping processes, you want a vendor that can cover a wide range of mechanical seal support requirements. This includes process side (flush), between seal (buffer/barrier), and atmospheric side (quench) mechanical seal support systems.

|

In addition to the standard API 682 Plans, your vendor should also provide optional components such as pressure and temperature gauges, flow meters, transmitters, strainers, cyclone separators relief valves, level gauges, and flush fluid cooling systems. With the proper design, any one or more of these components can significantly enhance the performance and reliability of a mechanical seal support system. |

Design Best Practices for Safety, Performance, and Maintenance

The design of the optimum mechanical seal support system involves far more than just the assembly of parts and components per a specific API plan. A properly designed mechanical seal support system also considers factors that promote safe operations and reduce maintenance costs.

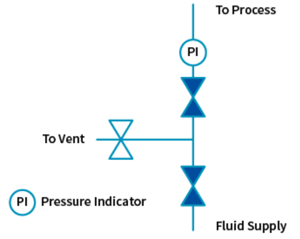

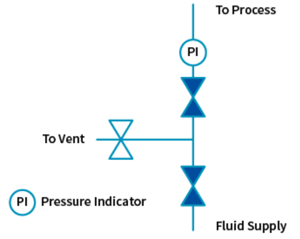

Designs always include the following:

- block-and-bleed valves on instrumentation so that they can be safely calibrated or removed for servicing;

- low point drains to quickly and safely purge buffer, barrier, or flush fluids when pumps are out of service;

- and tubing geometry and location of seal pot assemblies, heat exchangers, and panels to prevent accidental contact by operations personnel.

Best design practices ensure all tubing runs are sloping, use large radius bends, forego elbow fittings (whenever possible), and minimize the number of threaded connections—while remaining compliant with industry and local codes—to promote optimum flush fluid flows and eliminate leakage points.

|

A bypass loop included in the mechanical seal support system design can deliver a continuous supply of flush fluid whenever filters are replaced or cleaned. With this design addition, you don’t need to halt the pumping process just to perform planned maintenance

High-point vents allow seal support systems to easily be vented to clear entrapped air that could impede flush flow. Design elements like these can reduce downtime. And when you have dozens to hundreds of pumps in operation, add up to significant savings in maintenance time and costs.

|

The Added Advantages of a Local Presence

Consider the benefits of a global mechanical seals support vendor that also has a local presence. This can be one of the most important factors in choosing a mechanical seal support brand. A global reach and local presence give you the added advantages of:

- Quick response to any support issues, whether on-site, virtual, or phone

- Extensive inventory for on-demand part or component replacements or upgrades

- First-hand knowledge of your operations and specific mechanical seal support needs

- Access to a global network of industry and fluid process professionals

A mechanical seal support brand that offers a local presence can be a significant differentiator in the quality of service and support you receive.

Swagelok: A Global Brand With a California Presence

The Swagelok brand is known worldwide. For more than seven decades, Swagelok has brought industry expertise to consult, design, and manufacture high-quality fluid systems for industries in 70 countries. Swagelok Northern California, with facilities in Concord, Santa Clara, and Concord, serves 58 counties of northern California.

Our Field Engineering and assembly services teams bring deep fluid system expertise to the design and fabrication of easy-to-maintain, and safe-to-operate mechanical seal support systems. When you’re evaluating various mechanical seal support brands you’ll find that Swagelok’s industry experience, range of mechanical seal support systems, top-quality quality design and fabrication processes, and local presence make it an ideal partner.

To learn more about the products and services that Swagelok Northern California can provide to help improve the reliability and performance of pumps, mechanical seals, and support systems, contact our team today by calling 510-933-6200.