Conceptually, gas distribution systems are relatively simple. They deliver gases from a high-pressure source to the point of use. To operate safely and efficiently, the system must be designed with a solid understanding of the end-process as well as the physical environment or infrastructure of the facility. Without the proper gas distribution system design and fabrication of subsystems, you may run into problems such as:

- Gas leaks that increase operating costs

- Difficulty operating and maintaining the system

- Process interruptions and unplanned downtime

- Safety hazards that risk operator injury

If you’re planning to install a new gas distribution system or upgrade an existing system, you’ll benefit from Swagelok’s experience and expertise. We’ve been helping industries obtain the maximum benefit from their gas distribution systems with designs customized for process requirements and system fabrication using top-quality materials and components for decades.

Understanding Gas Distribution System Design Decisions

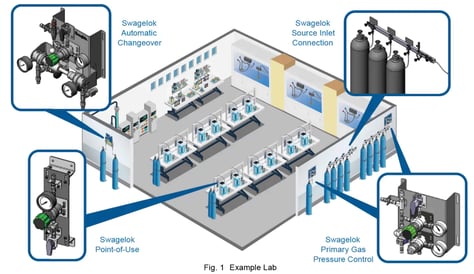

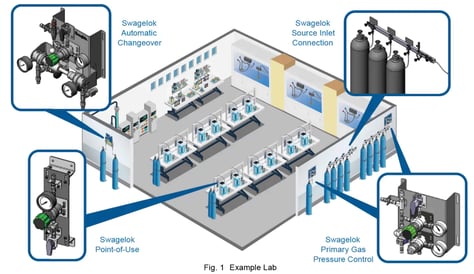

To understand the value of partnering with us, let’s consider the custom design decisions associated with each of our four gas distribution subsystems.

Source Inlet Subsystem

The source inlet subsystem connects the high-pressure gas source with the distribution system.

The connection may include hoses, tubing, and filters. Single gas cylinder connections use a simple hose and cylinder connector. Multiple cylinder connections usually require a manifold with several hoses and valves. Vent, purge, and relief functions help ensure the safe delivery of gas to the primary pressure control or automatic changeover subsystem.

|

Custom Design Solutions: Swagelok advisors work to ensure the source inlet subsystem uses the correct cylinder connector(s), minimize the number of connection points, specify special hoses for certain gases, and customize supports so that hoses don’t drop to the ground.

|

Primary Gas Pressure Control Subsystem

This subsystem is the primary pressure control, taking gas from the source and reducing it to the proper pressure and flow rate, using a single pressure regulator or dual pressure regulator arrangement.

|

Custom Design Solutions: Swagelok advisors will assess the process requirements to determine the correct inlet and delivery pressure. In most applications, a single-stage regulator is needed, but in the case where a twin-stage regulator is required, our advisors will explain the reason and benefit of that approach.

|

Automatic Changeover Subsystem

For processes requiring a continuous supply of gas, you’ll need an automatic changeover subsystem to seamlessly switch from one gas source to another. A smooth changeover is accomplished using staggered set points of two pressure regulators. This allows continued operations as the primary gas source is changed.

|

Custom Design Solutions: Swagelok advisors work with you to determine the changeover set points that minimize the amount of gas remaining in a depleted cylinder. This reduces wasted gas and can lower long-term operating costs. Each changeover subsystem is unique and Swagelok advisors will assess process requirements to ensure consistent, reliable operations.

|

Point-of-Use Subsystem

The point-of-use subsystem is the final stage in pressure control and is the least complex subsystem, typically consisting of a pressure regulator, gauge, and isolation valve. The point-of-use subsystem enables fine-tuning of the gas pressure prior to delivery to the test bench or process equipment.

|

Custom Design Solutions: Swagelok advisors design the point-of-use subsystem for convenient access and accurate adjustment by operators.

|

Swagelok Gas Distribution System Design Process

Swagelok Field Engineers know the value of gaining an in-depth understanding of your process requirements. With this in mind, they conduct a detailed on-site assessment of your gas distribution requirements. They’ll pay particular attention to factors that influence system performance and safety, as well as long-term operational flexibility. With pressure and flow being the critical parameters, these custom design decisions focus on:

- Specific pressure and temperature ratings and operating methods to match system requirements

- Pressure regulators selected to closely match inlet pressure requirements for optimum handle resolution (small amount of pressure change per handle turn) and control

- Pressure control and flow isolation components sized for a wide range of parameters to ensure the system can be used without modifications as needs change

- Pressure control and relief valves selected to safely manage the full range of potential pressures and flows

- Restricted flow orifices located close to the gas source to limit the flow rate in the event of a significant downstream leak or break

Swagelok modular panels are designed to reduce potential leak points by minimizing threaded connections. Clear, intuitive panel labels and mounting options can minimize accidental damage and promote safe operations and maintenance.

When the custom design is completed, you’ll receive detailed specifications for all the components comprising the gas distribution system.

Swagelok Gas Distribution System Fabrication

Once approved Swagelok technicians fabricate the custom system in our local facilities. We build gas distribution systems of the highest quality components, and with an extensive local inventory of components, we can quickly transform designs into functional gas distribution systems. With decades of experience designing and fabricating gas distribution systems, Swagelok applies the latest best practices and follows ISO 9001 quality standards.

All Swagelok gas distribution systems are thoroughly tested prior to delivery and they are backed by one of the best Limited Lifetime Warranties in the business.

Consult Swagelok for Gas Distribution System Design and Fabrication

Today, very few businesses have the resources to competently design and fabricate custom gas distribution systems. Limited budgets, an aging workforce, and other constraints may make it difficult for businesses to undertake these projects independently. Swagelok understands the challenges and approaches custom gas distribution system design and fabrication projects as a trusted partner. By working closely with you we gain a detailed understanding of your process requirements and customize and fabricate the gas distribution systems to provide safe and reliable performance and reduce operating and maintenance costs.

To learn how Swagelok Northern California can customize and fabricate gas distribution systems by providing expert on-site consulation and Assembly Services, contact our team today by calling 510-933-6200.

.jpg?width=800&name=Screenshot%202021-04-05%20235516%20(1).jpg)