Menu

Engineering Services

Product Lines

Resources

About

Shop

/1920x400/Thermoucouples_1920x400.jpg?width=1920&name=Thermoucouples_1920x400.jpg)

Meeting a thermocouple design & assembly challenge

Thermocouples are used in many day-to-day applications. In homes, businesses, and offices, they act as temperature sensors in our thermostats and flame sensors in our appliances’ safety switches. These electrical devices are simple, cost-effective, and offer robust measurement capabilities.

Thermocouples are used in many day-to-day applications. In homes, businesses, and offices, they act as temperature sensors in our thermostats and flame sensors in our appliances’ safety switches. These electrical devices are simple, cost-effective, and offer robust measurement capabilities.

An essential tool in a wide range of temperature management and measurement applications, the versatility of thermocouples means that their manufacture varies greatly. Depending on the application, they are available as probes, probes with independent connectors, transition joint probes, and even in bare-wire style and infrared models.

An effective thermocouple assembly can be critical to industrial operations and the monitoring of sensitive liquids, gases, and mechanical systems.

The client, a producer of chemicals and specialty components for the semiconductor industry, was dealing with a thermocouple assembly challenge. In order to effectively monitor temperatures in their assembly, they needed to create a complex mount that didn’t yet exist — within a two-week window.

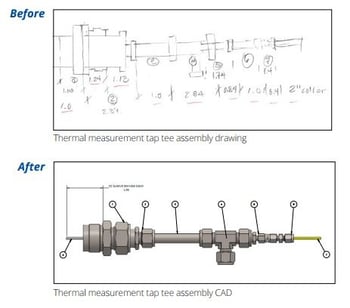

The in-house team was able to provide a rough pencil sketch of the basic design needed for their system, but they had no precise design, components, or engineering available to support it.

The system media involved a series of various semiconductor precursors, as well as services for low pressure and low temperatures, or a “cold trap.”

At the ready with expert technical advice, Swagelok Northern California’s in-house engineering team got to work immediately. With a pencil sketch in hand, they quickly crafted a clean CAD plan, from which they could roll through a series of refinements and iterations.

Once the drawings and CAD design had been worked out, the team delivered not one, but four unique custom assemblies — all within the customer’s critical two-week window.

The team at Swagelok Northern California is proud to offer quick, efficient service at any stage of a project, including the initial CAD development for a custom assembly. With engineering expertise backed by global capabilities, we can confidently meet complex specifications and requirements in any industry.

You can get help like this too. Visit the Assembly Services page to learn more.

Swagelok Northern California

Swagelok Northern California is a locally owned sales and service center of Swagelok, a company celebrating 75 years in business. We have locations in Fremont, Sunnyvale, and Concord, CA (USA). Phone: 510-933-6200.