It takes a wealth of knowledge and experience to keep a Northern California refinery smoothly running. However, there are many times when the resources you need to run smoothly lie beyond the refinery’s perimeter. Engaging outside technical experts that can identify and remedy problems or improve operational efficiency is often the fastest and most economically feasible way to keep things running.

Take, for example, sampling and analyzer systems. They provide critical information daily regarding process conditions and product quality. The range of analytic processes throughout the refinery varies from simple grab sampling systems to ensure wastewater is suitable for discharge to far more complex analyses of crude, natural gas, or alternative fuels. A single malfunctioning analyzer can result in costly problems—off-spec product or lead to environmental sanctions.

On-site Refinery Engineering for Sampling and Analyzer Systems

Reliable sampling and analyzer systems begin with an understanding of the specific refining process, location of the sample point, planned of existing infrastructure, and proximity of the analyzer to the sample point. That’s a lot of information to digest, and it takes a team of multi-disciplinary experts to deliver the right solution. Here’s where you can benefit from on-site refinery engineering services available from Swagelok. We bring our engineering expertise and global experience in helping refineries identify deficiencies, find the right solutions, or optimize sampling and analyzer processes.

The Value of On-site Refinery Engineering

When it comes to understanding a client’s processes, there’s no substitute for being on-site to assess the sampling and analyzer requirements, the infrastructure, and any other factors that influence the selection of components and system design. While one or two Swagelok Field Engineers may arrive on-site for the initial consultation, there’s a worldwide team of experts involved in the process.

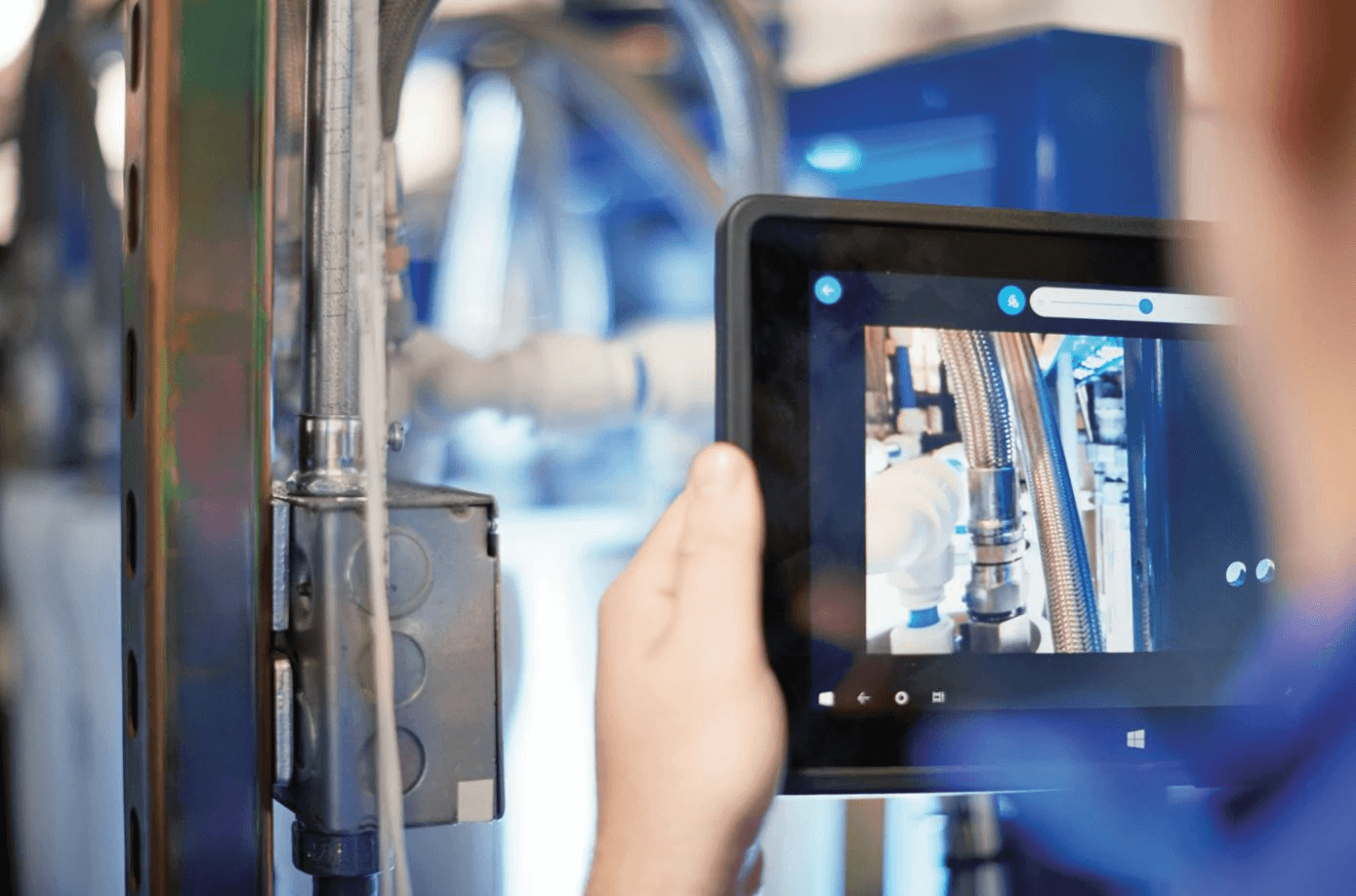

Using an augmented reality headset with a camera and microphone, the Field Engineer conducts a walk-through of the area immediate to the planned or existing sampling station. Participating in this walk-through via Microsoft Teams, remotely located Swagelok engineers and subject matter experts are virtually present. They have the same view as the on-site engineer. They can ask questions, discuss the system with refinery personnel, request a closer look at any particular area, assembly, or component. With the client’s permission, the session can be recorded for future reference.

Using an augmented reality headset with a camera and microphone, the Field Engineer conducts a walk-through of the area immediate to the planned or existing sampling station. Participating in this walk-through via Microsoft Teams, remotely located Swagelok engineers and subject matter experts are virtually present. They have the same view as the on-site engineer. They can ask questions, discuss the system with refinery personnel, request a closer look at any particular area, assembly, or component. With the client’s permission, the session can be recorded for future reference.

This virtual collaborative approach to on-site engineering support makes it easier to accurately identify existing or potential problems and arrive at the optimum solution or design for the sampling process.

On-site Refinery Engineering For Sampling And Analyzer Systems

Swagelok’s on-site refinery engineering covers a wide range of advisory and support services designed to improve sampling system reliability, reduce operating and maintenance costs, and identify hidden opportunities for system improvement. Our key support services include:

- Overall evaluation of sampling system health and risks;

- Product selection assistance;

- Component substitute recommendations for improved reliability and longer system life;

- Sample system design, including bill of materials and piping and instrumentation diagrams;

- Sampling system design optimization to reduce unnecessary analyzer calibrations; and

- Training and process recommendations.

Our global fluid systems are focused on helping you consistently and safely produce representative samples and accurately analyze those samples to ensure compliant refinery processes and product quality.

Swagelok, Your Partner in Refinery Engineering Support

We’re well aware of staffing and financial challenges facing the oil and gas industry. Many refineries’ resources are stretched. In-house expertise may not be available to address the specific need promptly. Here’s where Swagelok’s on-site refinery engineering support can fill the gap.

Whether it’s an overall analysis of a sampling system, detailed design specifications for a new or replacement system, or recommendations regarding components or sub-assemblies to optimize the sampling processes, you can rely on Swagelok to competently provide these engineering services. We bring technical expertise, application experience, and industry knowledge from around the world to improve sampling station and analyzer reliability and efficiency.

To learn more about the on-site refinery engineering support from Swagelok Northern California for sampling and analyzer systems contact our team today by calling 510-933-6200.

Using an augmented reality headset with a camera and microphone, the Field Engineer conducts a walk-through of the area immediate to the planned or existing sampling station. Participating in this walk-through via Microsoft Teams, remotely located Swagelok engineers and subject matter experts are virtually present. They have the same view as the on-site engineer. They can ask questions, discuss the system with refinery personnel, request a closer look at any particular area, assembly, or component. With the client’s permission, the session can be recorded for future reference.

Using an augmented reality headset with a camera and microphone, the Field Engineer conducts a walk-through of the area immediate to the planned or existing sampling station. Participating in this walk-through via Microsoft Teams, remotely located Swagelok engineers and subject matter experts are virtually present. They have the same view as the on-site engineer. They can ask questions, discuss the system with refinery personnel, request a closer look at any particular area, assembly, or component. With the client’s permission, the session can be recorded for future reference.