The accuracy of grab sample analysis depends on following sampling best practices while using reliable equipment to ensure a safe, representative sample. For Northern California refineries, Swagelok offers a complete package. A team of expert Field Engineers can help you choose the best sampling methods and recommend reliable Swagelok grab sampling systems for your refinery processes.

To better understand the value of these recommendations, it’s important to know what’s required to design a safe and efficient grab sampling system.

Requirements for Designing a Safe and Efficient Sampling System

Several factors influence selecting the right gas sampling equipment for a Northern California plant, such as:

- Maximum rated pressure

- Fluid temperature

- Ambient conditions

- Nature of fluid (hazardous/flammable)

- Sampling system material and surface treatment

- Need of purging system

Considering the complexity involved in the selection process, relying on auto sampling systems may seem like an easy decision. But, a manual sampling procedure is still the most reliable sampling method for many industries.

The manual grab sampling process enables operators for immediate in-situ field analyses and aids automatic online samplers for composite sampling. It’s important to note that manual grab sampling carries the risk of sample contamination, which can result in the misrepresentation of true process conditions. Handling the sample properly, beginning with its container, can mitigate the risk of contamination.

The choice of sample containment depends on the fluid’s phase composition and behavior. For highly volatile fluids, cylinders are perfect as they can retain sample pressure from the collection point to the laboratory. Similarly, bottles are more appropriate for non-volatile liquids or liquids with max vapor pressure.

The below table displays container recommendations based on fluid type:

| |

Container Type |

| Sample Phase |

Pressure-containing |

Non-pressure containing |

Sample receiver |

| Liquid |

Recommended |

Recommended |

Cylinder |

| Liquid |

Not recommended |

Recommended |

Bottle |

| Vapor |

Recommended |

Recommended |

Cylinder |

| Vapor |

Not recommended |

Not recommended |

Bottle |

It is imperative to note that if the sample temperature is more than 140°F (60°C), the operator must use a heat exchanger (sample cooler) to sample the fluid safely and accurately.

Speak with a Swagelok Field Engineer today and start designing the ideal grab sampling system.

Different Types of Swagelok Grab Sampling Systems

Swagelok offers two types of grab sampling systems:

1. Grab Sample Module (GSM)

It’s a closed-loop sampling system to analyze fluids (liquids and gasses) that stand at a risk of environmental contamination and need to be contained under a required pressure.

Salient Features

- Real-time sample capture inside a cylinder

- Retains fluid pressure

- Prevents sample fluid environment contamination

- Continuous flow to decrease flush times

- 316 stainless steel durable body to prevent accidental breakage

- Improved fluid routing control with customized Swagelok switching valves

- Flexibility to address cylinder overpressure with optional rupture discs and relief valves

Swagelok offers different variations of GSM assemblies depending on your requirements, such as:

- Standard liquid sampler with/without purge

- Standard gas sampler with/without purge

- Continuous flow liquid sampler with/without purge

- Continuous flow gas sampler with/without purge

Swagelok enables you to customize your GSMs as per different available options in the field of fluid type, flow pattern, dial range, quick connects, cylinder bracket size, end connections, etc.

However, all GSM assemblies would require a Grab Sample Cylinder (GSC) to collect the sample fluid, available in multiple cylinders and valve material options. Swagelok offers two types of GSC assemblies: standard (without purge option) or purge (with purge option). You can also customize the inner coating in different available options, such as electropolishing or PTFE.

2. Liquid-Only Sampling Module (GSL)

2. Liquid-Only Sampling Module (GSL)

As the name suggests, this system can only be used for liquid applications to draw and store non-evaporating samples inside glass bottles for a quick visual inspection. The switching valves used are the same as those used in the GSM systems.

Salient Features

- Suitable for liquids with low pressure

- Option to customize for:

- Fixed volume: To prevent accidental spillage of hazardous or high-pressure fluid

- Purging: To prevent solidifying spillage of fluid in dispensing needle and internal tubing

- Continuous flow: To retain continuous flow from inlet to outlet

Swagelok also offers GSL for:

- Non-toxic liquid sampling with/without purge option

- Continuous flow non-toxic liquid sampling with/without purge

- Non-toxic liquid sampling with purge and back purge

- Fixed volume sampling with/without flow

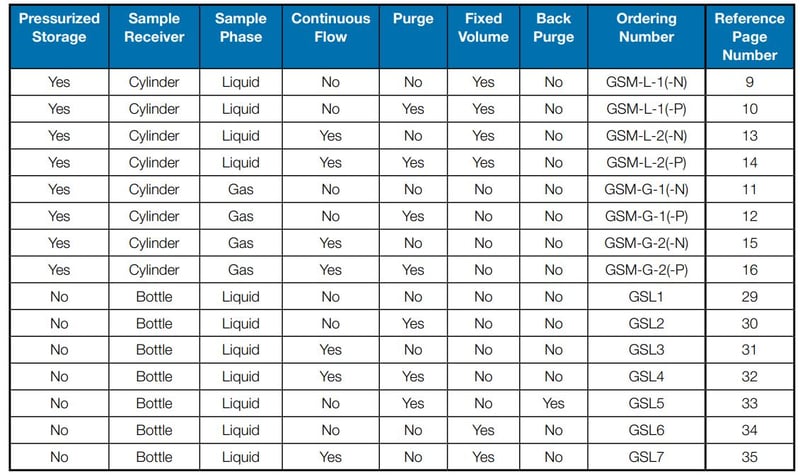

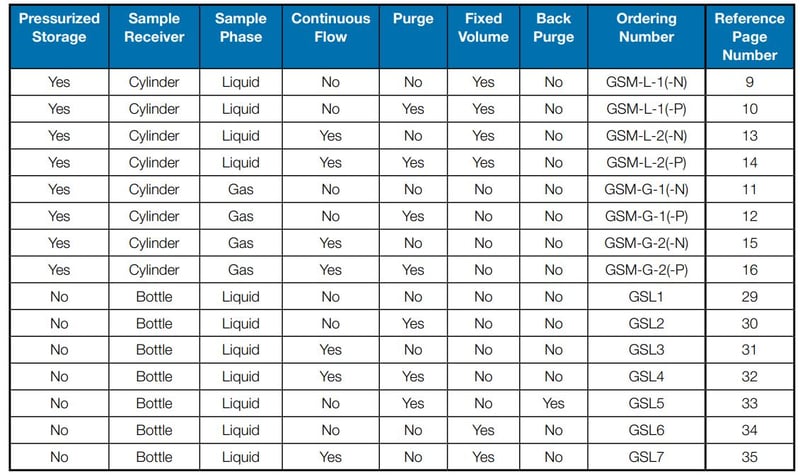

The table below recommends the ideal Swagelok grab sampling system under different system criteria:

Note: Assemblies are built to the sample bottles supplied by the customer; Swagelok is not a vendor of sample bottles. Field Engineers can recommend suppliers.

Best Practices with Swagelok SPU and SCO Units

To enhance the sample collection system, Swagelok engineers can customize your grab sampling panel to include Swagelok Point-of-Use (SPU) and Swagelok Changeover (SCO) subsystems.

Role of SPU

This subsystem can adjust the incoming pressure to the desired requirement at the critical point of use for optimized laboratory operations. The gas enters the subsystem by opening an inlet isolation valve and leaves at the desired pressure by adjusting the outlet regulator to the required level. It is easy to read pressure levels through inlet and outlet pressure gauges. SPU comes with both top-to-bottom and bottom-to-top flow arrangements to meet your setup needs with ease.

Role of SCO

If you want to seamlessly switch between different sample bottles during the process, an automatic SCO can do the job. It allows for varying changeover pressures with an SPU at the downstream as the last stage of control.

Note: The use of SCO and SPU subsystems are not limited to grab sampling systems only. Rather, they fit ideally for any industry looking to improve the safety and efficiency of gas distribution systems.

Things To Know About Swagelok Grab Sampling Systems

- Backed by the Swagelok Limited Lifetime Warranty

- Versatile mounting options for easier installation

- Standard sample systems can be configured using a part number table for simplified ordering

- Additional instrumentation is available, including gauges, meters, and flow indicators

- Local, factory-certified experts for local fabrication and support

Improve Your Grab Sampling Processes With Swagelok

If you want to design a grab sampling system that is safe and efficient for operators, Swagelok Field Engineers are happy to assist. They can analyze your existing distribution infrastructure and the fluid types involved to suggest customized Swagelok grab sampling systems to meet your specific operational needs.

To find out more about how Swagelok Northern California can help you design an ideal grab sampling system, contact our team today by calling 510-933-6200.

2. Liquid-Only Sampling Module (GSL)

2. Liquid-Only Sampling Module (GSL)