Semiconductor OEMs must design production equipment that yields the highest possible productivity, reliability, and technical capability. One of the most important aspects of semiconductor fabrication is thermal management. Therefore, semiconductor OEMs must design production equipment that mitigates thermal management challenges—meeting thermal demand, improving equipment insulation, and preventing coolant leaks.

Semiconductor OEMs in Northern California know how important even the smallest component is to successful production. Therefore, it’s essential that they take into account quality and reliability when selecting thermal management equipment for their production needs.

That’s where Swagelok Northern California comes in.

Selecting Thermal Management Equipment and Solutions

Swagelok Northern California offers a wide range of thermal management solutions for semiconductor OEMs.

To ensure thermal management equipment quality and reliability, semiconductor OEMs must take into account the temperatures equipment and material can withstand, the reliability of sensors, fittings and valves, and insulation.

- Temperature limits of equipment and materials: The temperature range of the equipment and materials must be able to withstand the production process and prevent drastic temperature changes. Every piece of equipment and material will have temperature specifications that should be checked to make sure they are able to withstand the production process.

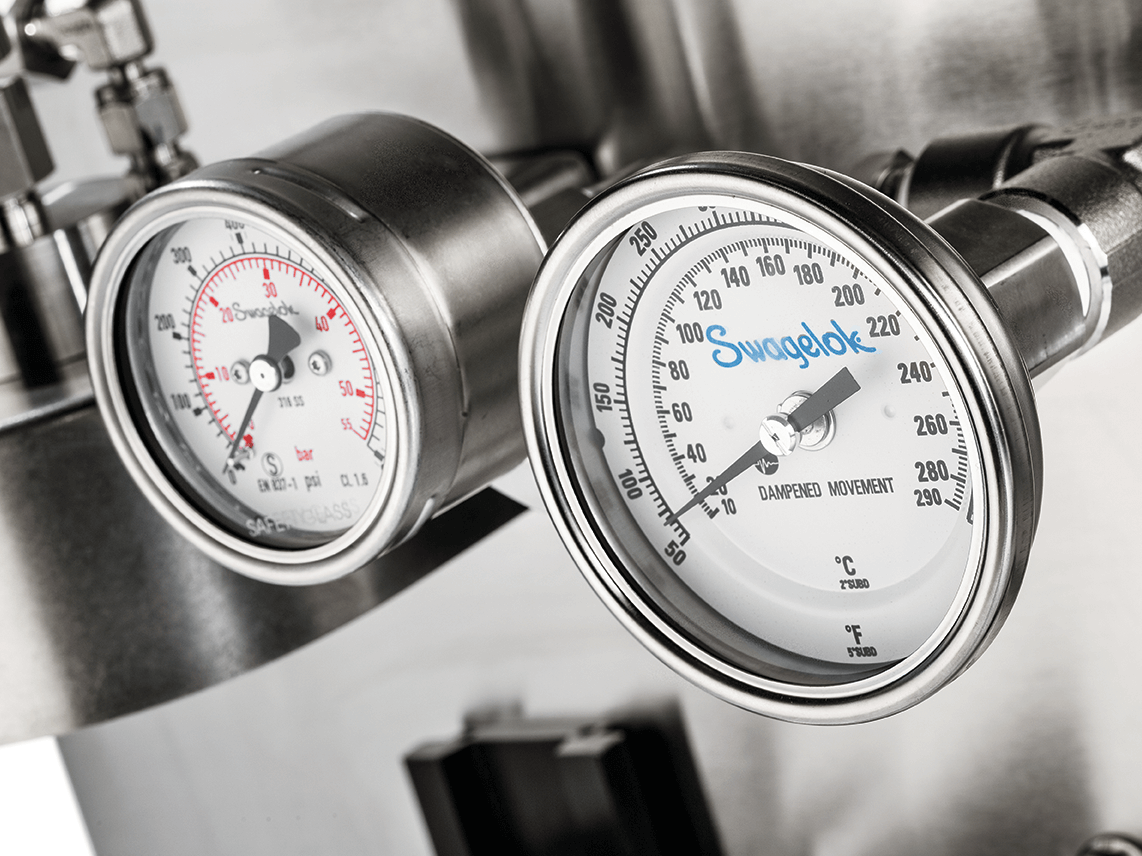

- Reliable sensors to monitor equipment and materials: Utilizing reliable sensors that give real-time data is imperative for semiconductor OEMs. Sensors can indicate changes to flow and pressure whereby changes may indicate leaks that are resulting in heat exchange. Further, sensors can monitor the temperature to directly examine heat exchange. This data can be used to determine if there is a problem during production. If so, production can be halted to prevent faulty equipment from leaving the facility.

- Proper fittings and valves: Proper fittings and valves prevent the unwanted dissipation of heat. It is important for semiconductor OEMs to ensure component connections don’t leave room for gas or fluid leaks. Small leaks can result in the inability to properly control temperature. It is often necessary for production facilities to have customized fittings and tubing to prevent leaks, thermal dissipation, and damage during semiconductor fabrication.

- Insulated components: An obvious, yet extremely important, consideration for thermal management by semiconductor OEMs is the use of insulated hoses, tubing, and lines. It is important to check the temperature ranges of these products to verify that they will work with production needs and limit heat exchange. Utilizing components that do not work in the requisite temperature range will result in heat dissipation and damage to semiconductor fabrication.

Swagelok Northern California goes above and beyond traditional boundaries to suggest custom components that can help OEMs save time, increase the speed of production, and reduce downtime to minimize associated costs.

Swagelok Northern California Has the Thermal Management Equipment and Solutions You Need

For more than 50 years, Swagelok Northern California has supported semiconductor OEMs and fabricators. Swagelok itself has advanced innovation with ALD diaphragm valves tested to 100 million cycles, springless diaphragm valves, fluoropolymer valves, and more.

Here’s a look at some of Swagelok’s high-quality solutions for thermal management:

| Swagelok Solution |

Purpose |

Temperature Limit |

|

Insulated hoses, tubing, and lines

|

Insulated lines to prevent heat dissipation |

Insulated options for temperature ranges -325°F to 1000°F (-200°C to 537°C) |

|

Measurement sensors (e.g. flow sensors)

|

Measurement sensors to aid in the accurate control of temperature and flow |

-40°F to 175°F (-40°C to 79°C) |

|

Valves

|

Control flow of gasses and liquids |

Many valves to choose from for a range of temperatures; For example, atomic layer deposition valves have full immersiablity up to 392°F (200°C) |

|

Fittings

|

Limit leakage of gas or liquids; prevent heat dissipation |

Many fittings to choose from for a range of temperatures; For example, PFA tube fitting can work with temperatures ranging from 70°F to 400ºF (20°C to 204°C) |

With so many options for thermal management, choosing the right equipment or material may feel overwhelming. Thankfully, Swagelok also has a team of experts ready to assist prior to, during, and after implementation. Further, Swagelok’s team of experts can provide consultation to determine how best to implement and upgrade existing equipment.

Swagelok Northern California has been on a mission to develop next-gen thermal management solutions to help semiconductor OEMs hit new performance benchmarks like never before. Our top-of-the-line equipment can provide exact thermal regulation during the production process to prevent heat dissipation that could lead to damaged semiconductors. Our sensors can detect small changes in flow and temperature and alert operators to make the necessary adjustments. Further, our insulated and bundled lines are designed to prevent heat dissipation.

To find out more about how Swagelok Northern California can help your thermal management solution needs, contact our team today by calling 510-933-6200.