Share this

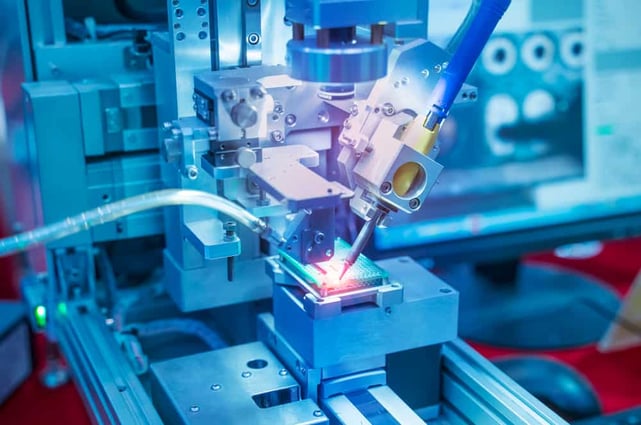

Selecting Thermal Management Applications for Semiconductor Manufacturers

by Morgan Zealear on 7/12/22 9:00 AM

Constant thermal failures in semiconductor OEM facilities is one of the major concerns that significantly affect ROI. Amongst many potential hotspots of thermal failures, hoses, insulations, regulators, and needle valves are some of the frequently observed weak links. For instance, extreme hot or cold temperatures can develop hardness and cracks on hose reinforcement, leading to hose failures. They can also lead to fugitive emissions. That calls for hoses, along with associated adapters and fittings to match with high temp standards and specifications. In this regard, Swagelok’s thermal management applications and expert engineering advice have helped many semiconductor OEMs in Northern California perform beyond the limitations of thermal challenges. Let’s have a look at some of the highly sought-after Swagelok thermal management applications.

Top Thermal Management Applications from Swagelok

High Temp Hoses

Swagelok offers hoses with customizable core tubes to address a wide range of temperature applications. The table below shows the list of different types of cores available along with their typical temperature range for your reference.

|

Hose Core Material |

Typical Temperature Range |

|

Metal |

-328°F and 849°F (-200°C and 454°C) |

|

Silicone |

-63°F and 599°F (-53°C to 315°C) |

|

Fluoropolymer |

-63°F and 446°F (-53°C to 230°C) |

|

Thermoplastic (Nylon) |

-40°F and 199°F (-40°C to 93°C) |

|

Rubber |

-40°F and 199°F (-40°C to 93°C) |

Apart from offering you the best solution, we also help you follow best practices in the host installation and usage through our bespoke technical customer support.

Insulated Tubings

Whether it is about steam supply or condensate return, heatproofing the flow of fluid inside can be a challenge for semiconductor OEMs. Swagelok’s insulated tubing solutions successfully isolate outer equipment from inner fluid influence and therefore reduce heat loss with ease. The 316 SS body coupled with low-temp PVC jacket keeps personnel safe from hot process and steam lines while offering a budget-conscious alternative to field-installed insulation of small-diameter tubing systems. These tubings are good to go with a process temperature of 204°C and a minimum service temperature up to –55°C.

Field Station Modules

Swagelok’s FSM reduces process gas pressure before transporting it to an analyzer. It effectively reduces the partial pressure of water vapor possible in the gas mixture to avoid condensation of the sample transport line. This directly reduces the overall system pressure as well. It comes with several customized options to mount heaters with a thermostat inside the enclosure for freeze protection or temperature maintenance.

Vaporizing Regulators

Incomplete vaporization of liquid samples can cause condensation outside. Swagelok’s pre-heated vaporizing pressure-reducing regulator can preheat gas samples to avoid condensation. The heater remains in direct contact with process media for maximum thermal efficiency. In this regard, Swagelok has two distinct models—KSV series and KEV series regulators. The KSV series is a steam-heated vaporizing regulator whereas the KEV series is an electrically heated one. The KEV series regulator further comes with T3 temperature classification for all heaters to bear surface temperatures up to 200°C. The maximum operating temperature of these regulators can be enhanced with customizable seat materials such as PCTFE, or PEEK.

N & HN Series Needle valves

Swagelok understands how important it is to accurately control flow rates under extreme temperature fluid conditions. The N series and HN series successfully meet those extreme pressure (up to 10 000 psig) and extreme temperature profile (-53°C to 1200°C) requirements with ease. With customizable packing and 316 stainless steel steam body, these needle valves have a maximum allowable leak rate of 0.1 std cm3/min. Moreover, they are API 624 tested for fugitive emissions. That means, at no point, will there be a leak above 100 ppm of methane due to thermal breakdown.

Swagelok Helps Semiconductor OEMs Optimize Thermal Performance

Swagelok has been on a mission to develop next-gen thermal management applications to help semiconductor OEMs hit new performance benchmarks like never before. We have been enabling semiconductor manufacturers in Northern California to assess, analyze, and select custom fluid management solutions for extreme temperature scenarios.

Moreover, our team of experts can offer you deep insight into your existing system condition either physically or through virtual support. For instance, while selecting the right hose for your system, our team can check for factors beyond min and max pressure and temperature limits. They can assess fluid compatibility, application type (static/dynamic), flow velocity, permeation, and absorption of system media. After a thorough analysis, our hose advisory service can provide you with the best customization to ensure long hose life and performance.

To find out more about how Swagelok Northern California can help you with selecting the right thermal management applications, contact our team today by calling 510-933-6200.

About Morgan Zealear | Product Engineer, Assembly Services

Morgan holds a Bachelor of Science in Mechanical Engineering from the University of California at Santa Barbara. He is certified in Section IX, Grab Sample Panel Configuration, and Mechanical Efficiency Program Specification (API 682), and he is well versed in B31.3 Process Piping Code. Before joining Swagelok Northern, he was a manufacturing engineer at Sierra Instruments, primarily focused on capillary thermal meters for the semiconductor industry (ASML).

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)