Download information on our general purpose & special application ball valves

With a unique coned-disc, spring-loaded seat; live-loaded, two-piece chevron stem packing; and 3-piece, swing-out design, Swagelok 60 series ball valves are designed for reliability and low maintenance for a wide variety of instrumentation and process applications.

With a unique coned-disc, spring-loaded seat; live-loaded, two-piece chevron stem packing; and 3-piece, swing-out design, Swagelok 60 series ball valves are designed for reliability and low maintenance for a wide variety of instrumentation and process applications.

They can be operated in a fully open or fully closed position; have end connections sizes range from 1/8 to 2 in. and 6 to 25 mm with additional sizes available; and are rated for -65 to 850°F (-53 to 454°C).

Their standard working pressure is up to 2200 psig (151 bar) with an option to increase to 3000 psig (206 bar). They come in stainless steel, brass, carbon steel, and special alloys, with a wide selection of seat materials including: Reinforced PTFE, Alloy X-750, Carbon/glass PTFE, PEEK, UHMWPE, Virgin PTFE; optional vent porting; on-off (2-way) and switching (3-way valves); and SC-11 cleaning available.

Learn more below. Fill the form to get quick links to the 60 Series Ball Valve interactive PDF, an overview, and the relevant catalog.

Tip: Get help choosing the right valves or have us build an assembly or subassembly for you using exactly the right components for your application.

End connection flexibility

Swagelok 60 series ball valves are available with a wide variety of end connections to fit the needs of your specific applications. Available end connections include:

Swagelok 60 series ball valves are available with a wide variety of end connections to fit the needs of your specific applications. Available end connections include:

- Swagelok Tube Fitting

- Female Pipe Thread

- Tube and Pipe Socket Weld

- Pipe Butt Weld

- Tube Extensions

- VCO® and VCR® Face Seal Fitting

- Sanitary Fitting

- Mixed End Connections

A variety of handles to meet your needs

Black lever handles come standard on 60 series ball valves, however there are several other handle options available:

Black lever handles come standard on 60 series ball valves, however there are several other handle options available:

- Lever-handle with colored sleeves—blue, green, orange, red and yellow are available

- Oval handles—standard sleeve is orange but other colors are available

- Locking brackets for lever and oval handles—allow you to lock valves open or closed

- Oval latch-lock handles—available for 63 and 65 series 2-way valves to lock valves open or closed

- Extended handles—two- and four-inch handle

extensions available

Ease of maintenance

Swing out design ensures ease of inline maintenance

Looking for a valve that can be maintained inline? The swing-out design of the 4-bolt valves allows fast and easy maintenance with the valve inline. Replacement seal kits are also available for applications that require them.

60 Series options and accessories

Low dead space inserts

- Reduce fluid entrapment around the ball, stem, and seats while the valve is open or closed

- Made from carbon/glass reinforced PTFE

- Not for use on steam, thermal, or fire series valves

|

|

Panel mount kits

- Can be installed on panels up to 3/16 in. for 62 series and 1/4 in. thick for 63, 65, 67, and 68 series

- Vertical or horizontal mounting

- Fit oval and lever handle

- Provide template for drilling holes

|

|

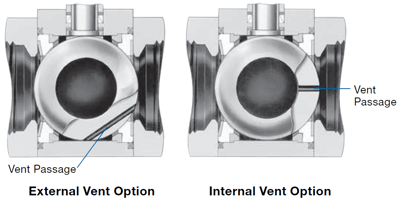

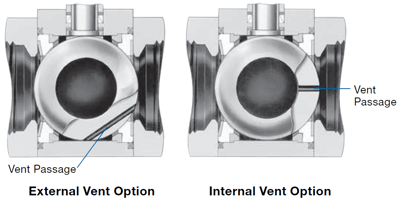

Vented valves

2-way ball valves are available with either an internal or an external vent

2-way ball valves are available with either an internal or an external vent- These vents are available for either upstream or downstream service

Protect your fluid system investment

/Warranty%20340x170%20(1).png?width=300&name=Warranty%20340x170%20(1).png) The Swagelok Limited Lifetime Warranty demonstrates our relentless commitment to quality and our customers. Every Swagelok product is backed by this promise for the life of the product.

The Swagelok Limited Lifetime Warranty demonstrates our relentless commitment to quality and our customers. Every Swagelok product is backed by this promise for the life of the product.

With a unique coned-disc, spring-loaded seat; live-loaded, two-piece chevron stem packing; and 3-piece, swing-out design, Swagelok 60 series ball valves are designed for reliability and low maintenance for a wide variety of instrumentation and process applications.

With a unique coned-disc, spring-loaded seat; live-loaded, two-piece chevron stem packing; and 3-piece, swing-out design, Swagelok 60 series ball valves are designed for reliability and low maintenance for a wide variety of instrumentation and process applications. Swagelok 60 series ball valves are available with a wide variety of end connections to fit the needs of your specific applications. Available end connections include:

Swagelok 60 series ball valves are available with a wide variety of end connections to fit the needs of your specific applications. Available end connections include: Black lever handles come standard on 60 series ball valves, however there are several other handle options available:

Black lever handles come standard on 60 series ball valves, however there are several other handle options available:

2-way ball valves are available with either an internal or an external vent

2-way ball valves are available with either an internal or an external vent/Warranty%20340x170%20(1).png?width=300&name=Warranty%20340x170%20(1).png)