Swagelok delivers leak-free, compact, cost effective result on tight timeline

The design and manufacturing processes involved in the semiconductor industry rely heavily on ideal environmental conditions. Gas exposure, moisture levels, air quality, and temperature all play a critical role in an operation’s success.

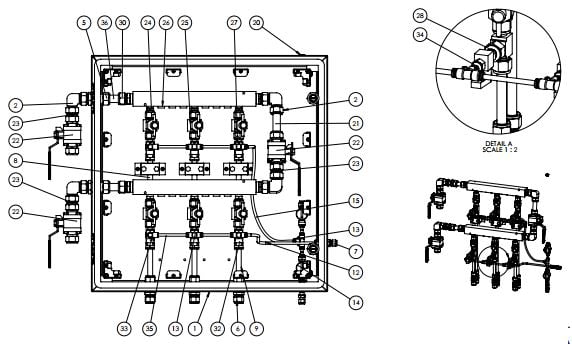

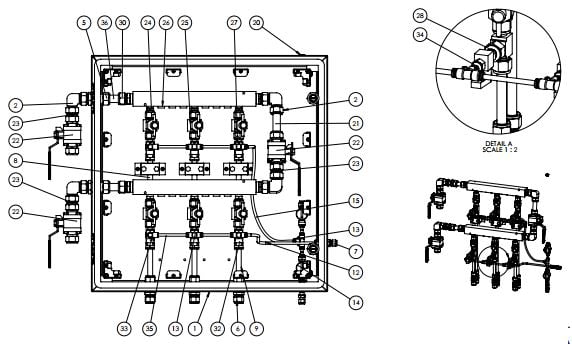

An original equipment manufacturer in the semiconductor industry, the client had specific requirements for the design of a chiller box. It needed to be cost effective while handling particular necessary flow rates without any kind of leakage. It also needed to fit in a small footprint as a final assembled system.

Outsourcing to fluid systems experts

The customer didn’t have in-house fluid system design engineering to fully develop the concept, however, so they required assistance in both optimizing the design and assembling the final chiller box. They were also working on a tight timeline with a limited budget. Without quick development and manufacture, the chiller box would stall other manufacturing processes and delay final shipment dates.

Quick design & production on a budget

The system needed to be capable of operations as low as -40 degrees Fahrenheit while handling glycol—an extremely difficult medium to contain without leakage. The combination of these requirements meant that high-performance components and high-level engineering were critical; the system would inherently have a strong tendency to leak.

With Swagelok Northern California’s in-house engineering skills and our wide array of components with high-performance end connections, the partnership between our team and the customer’s team enabled a solution. The team provided efficiently design assistance on the new system that met all the necessary criteria, fitted within a small footprint and impervious to leaks.

Assembly by certified technicians

The manufacturing team produced the chiller boxes well within the necessary deadlines and limited budgetary constraints. With the help of a single company, the client successfully met all of their project needs.

Swagelok Northern California takes budget constraints, tight timelines, and design challenges in stride. Since 1963, we have been fully dedicated to partnering with our customers, and take pride in meeting all of their needs through one reliable, expert team.

You can get help like this too. Visit the Assembly Services page to learn more.

/87%20(1).jpg?width=1920&name=87%20(1).jpg)