Many chemicals contribute to semiconductor fabrication at different stages of manufacturing. From oxidizing agents to etchants and solvents to active/inactive gases, these chemicals, when safely and continuously delivered to the processing unit, yield high-quality results. Thus, semiconductor fabs require a robust distribution system to support the safe and efficient supply of these chemicals in bulk. With the right components in place, the bulk chemical distribution system will ensure the utmost purity of the chemicals while enhancing productivity.

Contact Your Local Service Team

Components For Bulk Chemical Distribution System

The use of a bulk chemical distribution system comes from the need for semiconductor fabs to ensure:

- Uninterrupted supply of chemicals to the processing unit

- Chemical purity preservation with less interruption

- Waste minimization and cost savings

- Safety handling of hazardous chemicals

- Adhere to manufacturing standards

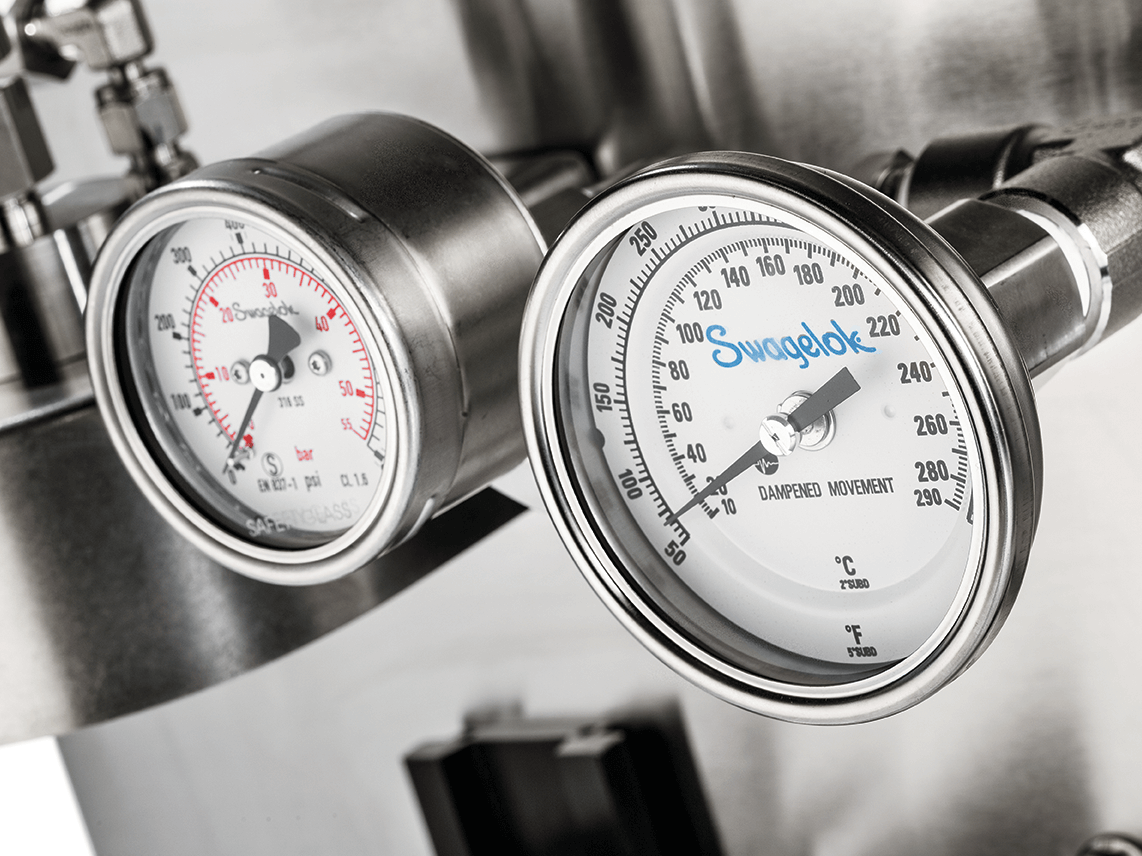

Swagelok’s ultra-high purity components offer the cleanliness, quality, and precision required for efficient chemical handling.

Solutions From Swagelok

Valves

Valves play a critical role in controlling the rate of flow of chemicals to the processing unit. Swagelok valves have quality seals, are high-purity, leak-free, and compatible with a wide range of chemical handling. Our UHP ALD valves are specifically designed for use in semiconductor manufacturing and offer the following features:

| Features |

ALD 20 |

ALD 3 and ALD 6 |

ALD 7 |

| Working pressure |

Vacuum to 20 psig (1.4 bar) |

Vacuum to 145 psig (10.0 bar) |

Vacuum to 145 psig (10.0 bar) |

| Burst pressure |

>3200 psig (220 bar) |

>3200 psig (220 bar) |

>3200 psig (220 bar) |

| Actuation pressure |

70 to 90 psig (4.9 to 6.2 bar) |

50 to 90 psig (3.5 to 6.2 bar) |

60 to 120 psig (4.1 to 8.27 bar) |

| Temperature |

50° to 392°F (10° to 200°C) |

32° to 392°F (0° to 200°C) |

Valve body from 32°F (0°C) to 392°F (200°C) Actuator from 32°F (0°C) to 302°F (150°C) |

| Flow coefficient |

1.2 (MSM) or 1.7 (straight pattern) |

0.27 or 0.62 |

0.7 Cv |

| Body material |

316L VIM-VAR or Alloy 22 |

316L VIM-VAR stainless steel |

316L VIM-VAR stainless steel |

In addition, Swagelok also offers diaphragm valves, bellows valves, and check valves.

Hose and Tubings

Hoses and tubings are critical to safely delivering chemicals to the manufacturing chamber. While doing so, it is essential that the hose/tubes can keep the temperature condition of the chemicals intact. Temperature fluctuation during delivery can bring a whole set of challenges. Too hot, and it can be unsafe to handle for operators. Too cold, the condensate may mix with the chemicals and damage the product.

Swagelok hoses and tubings are insulated to prevent temperature fluctuations during chemical distribution. Our W Series PTFE hose is perfect for addressing the range of process demands—temperature range, chemical type, and insulation requirement. The W Series PTFE hose has the following features:

| Material |

PTFE core with 304 stainless steel reinforcement braid |

| Working pressure |

Up to 3000 PSIG (200 bar) |

| Temperature range |

-65°F to 450°F (–53 to 230°C) |

| Nominal size |

⅜, ½, ¾ inches. |

Our convoluted metal tubing or PFA flexible tubing products are also suitable for use in highly-demanding semiconductor manufacturing applications.

Fittings

Swagelok fittings are compatible for use in the semiconductor fabrication process and with a wide range of chemicals. The ultra-high purity weld fittings are made of 316, 316L, 316L VAR, and 316L VIM-VAR stainless steel materials and offer an excellent surface finish. Take a look at our range of weld fittings, O-ring face seal fittings, and metal gasket face seal fittings.

Regulators

Regulators are important units that control the feed of chemicals in the system. Swagelok HF series pressure regulators are ideal for pressure control in high-purity applications such as semiconductor manufacturing. Our K series and RHPS series regulators are also ideal for maintaining pressure control on semiconductor fluid distribution systems.

Filtration Unit

Filtration units such as Swagelok's UHP inline gas filters are ideal for removing particulates and impurities to maintain the strict cleanliness standard required in semiconductor fabs.

Swagelok Can Help You Meet and Exceed Required Semiconductor Fabrication Standards

Safety should be the number one concern when dealing with bulk chemical distribution. The robust and leak-proof components from Swagelok can handle the high pressure at the inlet from the bulk chemical source. By ensuring temperature and purity control throughout the process, Swagelok components stand out as an ideal choice for bulk chemical distribution systems for semiconductor fabs.

Consult with Field Service Professionals

Swagelok also offers on-site design and assembly services if you want to evaluate and optimize your existing distribution system design. Our team of experts can perform a field audit and provide consultation and design assistance so your bulk chemical distribution system can meet all requirements.