In the ideal world, natural gas pressure regulators are installed and work properly without any significant downtime. Regularly scheduled review of their operations or testing might be all that’s needed to keep things running smoothly. However, the ideal world doesn’t accurately describe most Bay Area refineries. With complex, high-temperature, high-pressure hydrocarbon processes running around the clock, there’ll always be several maintenance tickets in the queue.

In an effort to reduce those maintenance issues, let’s focus on natural gas pressure regulator troubleshooting. Compared to many of the more complex fluid systems such as centrifugal pumps and seal support systems operating in local refineries, gas pressure regulator troubleshooting isn’t nearly as complicated. Let’s start by looking upstream of the regulator.

The Source of the Problem May Be Upstream

Between the gas source and the regulator in question, it’s not uncommon to find problems that impact gas pressure and flow. Before blaming the regulator, start your natural gas pressure regulator troubleshooting upstream at the source and work your way through to the regulator in question, checking for:

- Unexpected changes in delivery pressure at the source

- Damage to tubing or piping that reduces delivery pressure

- Recent replacement of portions of the tubing or piping run

Regulator location can also be a factor regarding poor performance. Elbows, valves, meters, and changes in piping diameter located upstream and proximate to the regulator can cause flow turbulence that makes it difficult for the regulator to properly match the downstream pressure. To avoid this problem, locate the regulator at least 6-10 pipe diameters downstream of any of these components.

When a Regulator Fails To Maintain Required Pressure or Flow

If the source of the problem can’t be found upstream, it’s time to focus on the regulator itself. In gas distribution systems, primarily for supplying industrial gases to analyzer stations in refineries, the first step in the diagnosis is determining if the regulator is properly sized.

Check for Improperly Sized Regulators

A regulator should be sized to meet the pressure and flow requirements of the process. If the regulator hasn’t been properly sized you’re virtually guaranteed problems.

If the regulator is too big for the application, your poppet and seat will be too large, allowing too much flow. When the regulator opens, it will allow more flow than expected and the regulator will be doing more work than actually required. As a result, you'll see more fluctuations and spikes in your downstream pressure.

If the regulator is too small for the application, the seat and poppet are undersized. The regulator will open as much as possible to allow as much flow as it can, though you’re operating closer to the choke flow range. As a result, you’re likely to erode the seat faster than if you used a properly sized regulator.

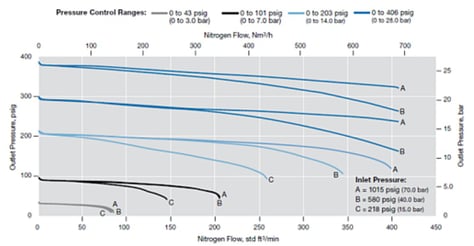

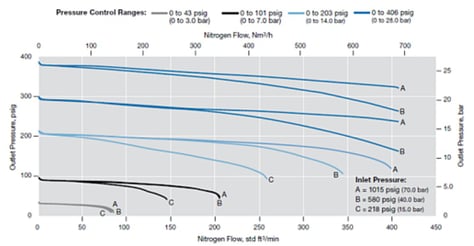

Every regulator will have a flow curve that describes its optimum performance range. That information should be provided by the manufacturer. If you don’t have that information, some vendors provide online tools to generate flow curves based on user-specified application parameters.

A flow curve illustrates a regulator’s performance comparing outlet pressure and flow rate. The curve depicts how a regulator will respond as flow varies in a system.

As a rule of thumb, a gas regulator should be sized so that the process requirement is no greater than 80% of the regulator’s rated capacity. But in too many instances, I’ve seen regulators selected by guesswork. Whether you’re installing a regulator as part of a new gas distribution system, replacing a regulator because of changes to an existing gas distribution system, or doubtful about the capacity of an installed regulator, guidance from an experienced fluid system engineer will ensure you’re installing a correctly-sized regulator.

Check Downstream for Choked Flow

Sometimes the gas pressure regulator isn’t the problem. Downstream conditions are causing choked flow and no amount of adjustment to the regulator will solve the problem. Choked flow results from changes in flow path cross-sectional area associated with fittings, orifice plates, and valves. Pinched tubing could also be the cause. You may also see it when gas flow is exiting tubing into a vessel or is released to atmosphere. Look for recent modifications to downstream infrastructure to ensure you’ve identified and eliminated any problems there.

Check for Mechanical Issues

If you’ve ruled out regulator sizing issues, it’s time to consider mechanical issues. In most instances, a simple part replacement solves the problem.

Regulator creep is an increase in outlet pressure that occurs when pressure escapes from the regulator body even though the poppet is closed. The source of the problem is usually associated with seat contamination. Particles in a high flow gas stream can:

- Create indentations in the seat, eventually creating a leak path

- Become lodged between the seat and the poppet, ruining a leak-proof seal

- Damage the poppet, preventing proper operations

To remedy the problem you can replace or clean the valve to remove particulates. If the valve seat is damaged, you may be able to obtain a replacement from your vendor. In the worst case, you’ll need to replace the entire regulator. Whether you’re replacing the valve seat or the entire regulator, it’s recommended that you add a filter upstream of the regulator to prevent particles from reaching the regulator.

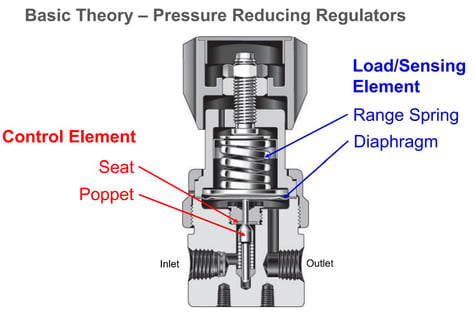

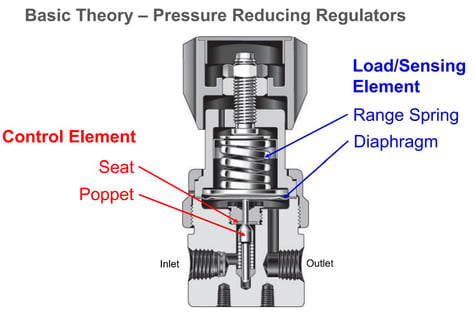

If, on the other hand, the regulator isn’t achieving the required pressure, it’s likely a problem with the regulating spring (load element/range spring in the illustration above). This can be an easy fix. Simply replace the regulating spring with one rated for the required pressure range.

Dealing With Supply Pressure Effect

As a gas cylinder empties, the supply pressure is reduced, yet at the same time, the outlet pressure can increase, making it difficult to maintain a constant gas pressure for a system. This is the well-known supply pressure effect. This problem commonly occurs when single-stage regulators are used in systems where there’s a high-pressure differential between inlet and outlet. The remedy for this problem is to replace the single-stage regulator with a two-stage regulator. It can significantly reduce the supply pressure effect and maintain a consistent outlet pressure.

Let Swagelok Assist With Gas Pressure Regulator Troubleshooting

The aforementioned are potential problems that can plague natural gas pressure regulators; especially in refineries located in Rodeo, Benecia, Martinez, and Richmond. For the experienced fluid systems engineer, these problems are relatively easy to detect, but in the event that you’re having trouble determining the actual source or the best solution to solve the problem, local field engineers at Swagelok are available to help with the diagnosis and recommend the appropriate solution.

Our facilities in Concord, Santa Clara, and Fremont carry an extensive inventory of top-quality gas distribution system parts, components, and assemblies. Experienced technicians can fabricate custom solutions for delivery to any Bay Area refinery. Whether you need assistance with natural gas regulator troubleshooting or solutions specifically designed to solve the problem, Swagelok is your local resource with global experience to assist you.

To find out more about how Swagelok Northern California can assist you in troubleshooting and revolving gas pressure regulator problems by providing expert on-site consultation, contact our team today by calling 510-933-6200.