Share this

How Do Gas Pressure Regulators Work for Industrial Processes?

by Morgan Zealear on 4/29/21 8:45 AM

Any industrial process that requires industrial gases in its operations depends on gas distribution systems to deliver the gases from source to point-of-use safely and reliably. Among the cylinder, hoses, gauges, and other components that comprise a gas distribution system, gas pressure regulators play one of the most critical roles—controlling gas pressure. For anyone new to the operations or maintenance of a gas distribution system, it’s well worth understanding how gas pressure regulators work.

How Do Gas Pressure Regulators Work?

In the simplest explanation, a gas pressure regulator reduces the inlet pressure to a lower outlet pressure and maintains a set outlet pressure, minimizing fluctuations in the inlet pressure.

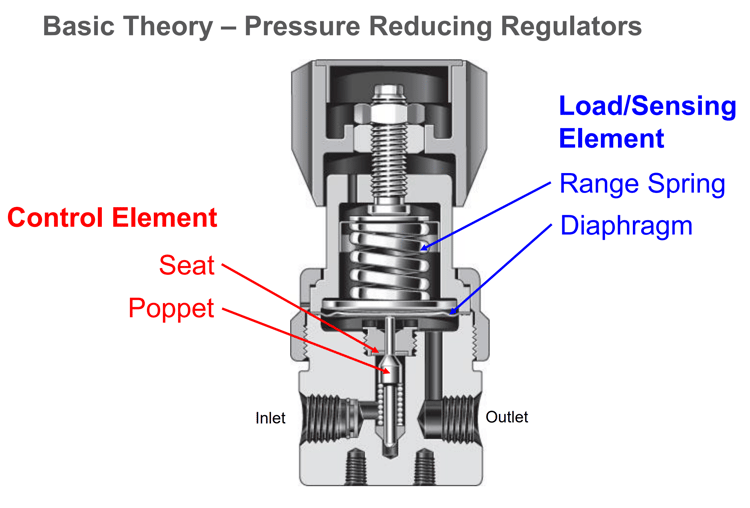

There are three elements in the regulator that control this process:

- Control element: also known as a poppet; is a spring-loaded valve

- Sensing element: a piston or diaphragm

- Load element: a spring

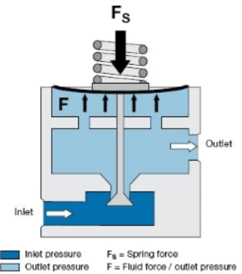

The interaction between these elements establishes and maintains the pressure in the following way:

|

|

For a more detailed understanding of the science of gases, pressure, volume, temperature, and flow in “Pressure Regulators Explained - Opening the Box of Mystery”.

Let’s explore each of these elements to help gain a better understanding of how materials and design influence the performance of the gas pressure regulator.

A Closer Look at the Elements in a Gas Pressure Regulator

Most regulators use a spring-loaded “poppet” (a rising and falling valve consisting of a disk at the end of a vertically set stem) for the control. The poppet includes an elastomeric seal to ensure a tight seal with the valve seat when the poppet is closed. A thermoplastic seal is used in some high-pressure gas regulator designs. The seal must be chemically compatible with the gas that flows through the regulator.

The sensing element can be a diaphragm or a piston. A diaphragm is a thin disc-shaped elastomer (also compatible with the gas) that is used to sense changes in outlet pressure. In many regulators, the disc is made of thin metal. Diaphragms are preferred in low-pressure applications. Compared to a piston, a diaphragm can be more readily sized to provide a larger sensing area and thus provide higher accuracy in maintaining the correct gas pressure.

In comparison to a diaphragm, a piston design is more rugged and appropriate for higher outlet pressures. A piston does not respond as quickly to pressure changes because of the friction between the piston seal and the regulator body. As a result, the piston design is more appropriate for applications where lower accuracy in outlet pressure is acceptable.

The loading element determines the pressure set-point. It is usually a mechanical spring that exerts a force on the sensing element (piston or diaphragm) which in turn opens the poppet. Most regulators adjust the pressure set-point by adjusting the force exerted by the mechanical spring. An adjustment screw or knob turned clockwise tightens the spring and increases set pressure. Turning it counterclockwise decreases set pressure. Alternatively, many regulators use a pressure signal captured within a dome above the sensing element in order to provide an accurate loading element that may be controlled by a pilot signal elsewhere. This is often utilized to ensure worker safety in hazardous environments, or to remotely control process pressure from an instrumentation control room.

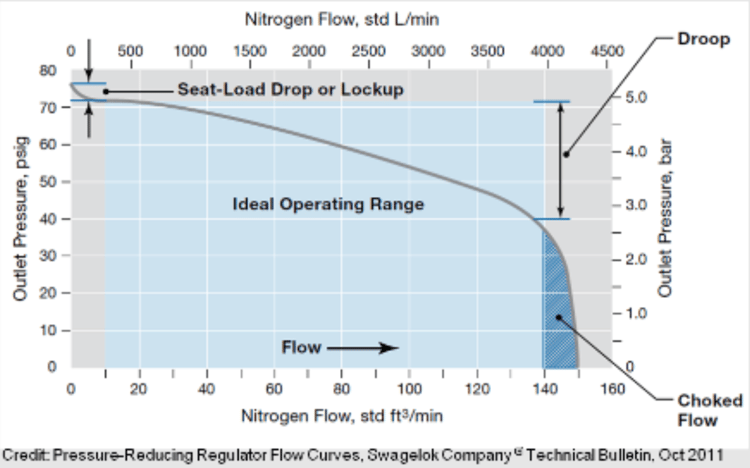

The Flow Curve Describes the Regulator’s Operating Range

Every gas pressure regulator has a flow curve that describes its operating range. The flow curve is important in determining the useful regulating capacity. The flow curve has three sections:

- Seat-Load Drop or Lockup indicates the pressure above the set-point required to completely shut the regulator valve and prevent gas flow. When too much pressure builds up the gas regulator closes the poppet.

- Ideal Operating Range is the area below the flow curve where the regulator provides the greatest control.

- Choked Flow is a limiting condition where any reduction in downstream pressure will have no effect on the flow rate for a fixed upstream pressure and temperature. In this state, the regulator valve is fully open and is no longer regulating pressure.

Pressure regulator accuracy is determined by plotting outlet pressure against flow rate. As the flow rate increases the outlet pressure drops. This relationship is termed “droop.” The less droop a pressure regulator exhibits over a range of gas flow, the greater its accuracy in maintaining a set pressure.

The last factor to consider is the Supply Pressure Effect. As the inlet pressure drops, say as a cylinder is nearing empty, the outlet pressure will increase. Sizing the regulator correctly for the application and using two-stage regulation are two important factors in sizing appropriately.

Single- and Dual-Stage Gas Pressure Regulators

Most gas distribution system designs feature single- or dual-stage regulators. Single-stage regulators have limited ranges of inlet pressure and/or flow rates. They are appropriate for small pressure reductions, for example, reducing plant compressed air service from 150 psi to 70 psi to operate air tools in the shop.

Dual-stage regulators easily handle wide ranges of inlet pressures and flows, as well as the decreasing inlet pressure typical of gas cylinders. Dual-stage regulators are actually two regulators contained in a single regulator body. They include the components of a single-stage regulator with an additional stage that includes a second pressure adjusting spring, diaphragm, and poppet assembly. The advantage of dual-stage regulators is a near-complete elimination of the Supply Pressure Effect. The first stage pressure is set by the manufacturer. The second stage is adjustable by the user.

Factors That Influence Gas Pressure Regulator Success

Selecting the right gas pressure regulator requires a good understanding of several factors specific to the industrial process and the type of regulator. A knowledgeable, experienced fluid systems engineer will carefully consider the following factors when recommending the right gas pressure regulator to work with an industrial process:

- point-of-use application

- operating temperature range

- industrial gas to be used

- toxic or flammable gas

- inlet and outlet pressure ranges

- range of inlet pressure fluctuations

- allowable variation in outlet pressure

- required flow rate

- regulator material compatibility with the gas

These factors will help guide the selection of the type of gas pressure regulator that works best for the process. And, the review of the regulator flow curves for each of the possible regulators will guide the selection of the specific gas pressure regulator for the process.

Swagelok: Gas Regulator and Industrial Process Expertise

For more than 50 years, Swagelok has been assisting industries that rely on safe and reliable delivery of fluids and gases for their daily operations and manufacturing process. Swagelok is your local source for technical guidance, regulators to meet almost every gas distribution need, and design and assembly services to provide you with gas distribution systems tailored to your specific requirements. The components and gas distribution systems sold and assembled by Swagelok are backed by our Limited Lifetime Warranty.

To find out more about how Swagelok Northern California can assist you in the selection of gas pressure regulators and the design of gas distribution systems by providing expert consultation and assembly services, contact our team today by calling 510-933-6200.

Morgan Zealear | Product Engineer – Assembly Services

Morgan Zealear | Product Engineer – Assembly Services

Morgan holds a B.S. in Mechanical Engineering from the University of California at Santa Barbara. He is certified in Section IX, Grab Sample Panel Configuration, and Mechanical Efficiency Program Specification (API 682). He is also well-versed in B31.3 Process Piping Code. Before joining Swagelok Northern California, he was a Manufacturing Engineer at Sierra Instruments, primarily focused on capillary thermal meters for the semiconductor industry (ASML).

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)