Share this

Communicating Your Gas Panel Design Specification: What Your California Vendor Needs to Know

by Malik Durojaiye on 6/17/21 9:00 AM

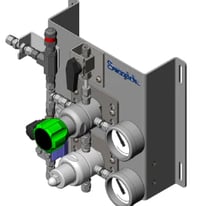

Gas distribution systems are commonly used in many facilities within industries such as petrochemical, biotechnology, and semiconductor for a wide variety of applications. Gas distribution systems must deliver gases from a high-pressure source to the point of use at a specified flow rate and pressure in a safe and effective manner. Gas panels, one of four critical subsystems of gas distribution systems, are the primary pressure control point that act as the first stage of managing high-pressure gas.

When a new gas panel for a gas distribution system is needed, it is important to understand the gas panel design specifications required to efficiently communicate expectations with a local gas panel vendor. Below, I will highlight the key gas panel design specifications required to properly design a reliable and effective gas panel suited for a specific application.

Key Gas Panel Design Specifications

Knowing what gas panel requirements to specify to a vendor allows for effective communication resulting in a quicker turnaround time to produce a gas panel configuration for a given application. Whether the point of use is an analyzer, process equipment, or a laboratory, the following specifications are required to determine a gas panel configuration, necessary components, materials of construction, and required instrumentation:

- Application and gas type

- Pressure

- Flow rate

- Temperature

General Specifications

Gas panel vendors must first understand the gas distribution application and gas type; in other words, which gas is being distributed and what is the point of use. Gas type and temperature can help determine what type of materials must be used to maintain equipment integrity. Additionally, gases that may be harmful to the environment and/or individuals in or near the facility may require additional safety considerations. For example, compression fittings can be used instead of threaded connections to reduce the likelihood of leakage and maintain safe operations. Similarly, restricted flow orifices can also be strategically implemented close to the gas source as an added level of leakage prevention.

As gas must be delivered to a point of use at a specified flow rate and pressure, flow rate and pressure considerations are critical for gas panel functionality. However, determining the required flow rate and pressure involves a detailed calculation based on gas type and application. Experienced fluid systems engineers should be consulted to perform this calculation or verify flow rate and pressure calculations.

Specifying a Pressure Regulator

There are two important factors that influence the control of gas pressure:

- Droop is the difference in delivery pressure between the zero-flow conditions and the maximum pressure regulator flow capacity.

- Supply pressure effect is the variation in the delivery pressure as the cylinder empties and the supply pressure decreases.

For more information, check out these pressure regulator resources.

Gas panel pressure regulators reduce the pressure of the gas supplied from a high-pressure cylinder to an acceptable level that can be safely used at the point of use. Gas distribution systems can either use a single-stage or dual-stage pressure regulator to reduce the supply pressure in either one or two steps, respectively. Both regulators respond differently to changes in supply pressure and have different droop characteristics.

If it is acceptable to have a relatively high supply pressure effect as the gas cylinder empties with little droop at varying flow rates, a single-stage regulator may be specified. Single-stage regulators are often used when constant outlet pressure is not critical, there is little variation in inlet pressure, or intermittent readjustment of delivery pressure does not pose an issue.

If it is acceptable to have a steeper slope in droop at varying flow rates with minimal supply pressure effects as the gas cylinder empties, a dual-stage pressure regulator may be specified. Dual-stage regulators are often used in applications that require a constant outlet pressure during the entire lifecycle of the gas cylinder. External components may be required to minimize droop depending on the implementation.

Additional Considerations

If process changes are anticipated in the future, this should be communicated to a gas panel vendor. Process changes are typically inevitable and considering this factor upfront can save time down the road. Pressure controls can be sized to accommodate a wider range of flow rates and pressures, allowing the ability to meet future process conditions without needing to alter the gas panel.

Seek Local Expertise for Optimal Gas Panel Designs

As the primary pressure control point, gas panels are critical for proper gas distribution system functionality and require careful attention during the gas panel design specification process. Communicating these key gas panel design specifications to your vendor can help to ensure reliable and efficient gas distribution from a strategically designed configuration with proper materials of construction.

Whether you are looking for a new custom gas panel design solution or are experiencing inefficiencies in your current gas distribution system, Swagelok Northern California has decades of experience and expertise in gas distribution systems and gas panels. If additional information is required to configure your gas panel, our Field Engineers would be happy to provide an onsite visit to further specify the design.

At Swagelok, we design gas panels based on best practices to deliver safe and reliable panels that are both easy to operate and easy to maintain. Our gas panels are locally fabricated, locally tested, and are backed by our leading Swagelok Limited Lifetime Warranty.

To find out more about how Swagelok Northern California can use your gas panel design specifications to custom configure a gas panel suited for your needs, contact our team today by calling 510-933-6200.

About Malik Durojaiye | Field Engineer, Assembly Services

Malik Durojaiye began his Swagelok career in 2019 as a Custom Solutions Engineer in our Assembly Services group. Prior to Swagelok, Malik developed as a design engineer as well as a manufacturing engineer for 6 years serving Kentucky and California with Altec Industries; a leading provider of products and services to the electric utility, telecommunications, tree care, lights and signs, and contractor markets.

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)