Share this

Analyzer Shelter Safety in California Refineries Begins With Well-Designed Sampling Systems

by Morgan Zealear on 5/20/21 9:00 AM

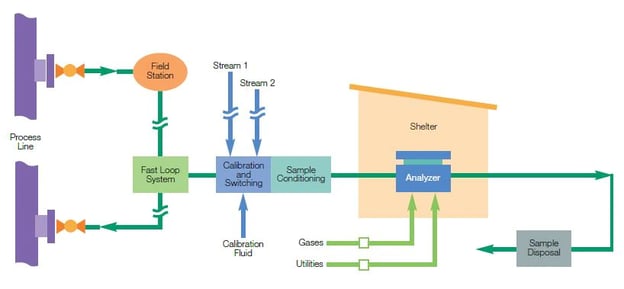

Analyzer shelters provide a common location for the protection of analyzer equipment, reliable analyses, and safe operations. An analyzer shelter should provide the proper environment for consistent, accurate analysis. When your employees are working within an enclosed shelter, they are protected from potential hazards caused by leakage of toxic liquids or gases. But, analyzer shelter safety should continue outside the shelter, as well. A sampling system designed to reliably and safely obtain a representative fluid sample from the sample point and deliver it to the analyzer station can ensure this safety.

Analyzer Shelter Safety Begins With a Properly Designed Sampling System

To design a reliable and efficient sampling point, you need to clearly understand process conditions, fluid properties, analytic requirements, and relevant regulations. To start off on the right track, I recommend working with fluid systems engineers experienced in the design of sampling solutions for refineries. They bring hands-on design experience to address critical decisions such as:

- Optimum sampling point location: one that provides a truly representative sample and is easily accessible for inspections and maintenance

- Eliminating or minimizing dead legs, such as tee fittings that can contaminate sample quality

- Type of sampling system: closed loop or fast loop; depending on fluid characteristics, process conditions, and analytic requirements

- Sample probe design: diameter, length, taper, and attachment style (flange, threaded, through-hole welded, or welded) to consistently capture a representative sample

Efficient design also includes the transport from the sample point to the analyzer shelter. To maintain the representative sample quality during transport, a fluid systems engineer may recommend a cooling system to protect the analyzer from high-temperature samples. Conversely, a heat trace along a transport line may be required to prevent the sample fluid from congealing in cold temperatures or prevent condensation that could damage the analyzer.

Assess the Pros and Cons of Continuous or Closed Loop Design

A continuous flow of process fluid to the analyzer station can significantly reduce the time required to obtain a sample, but the costs of the system will be greater. A closed-loop system will likely require a lag time calculation and purging to clear stagnant fluid from the transport line prior to analyzing the sample. An experienced fluid systems engineer will explain the pros and cons of each option, make the required calculations, and recommend the appropriate sampling system design.

Sampling System Designed for Safety

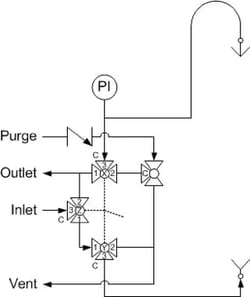

A safe sampling system design incorporates components and features that minimize the possibility of failure, as well as limit the degree of harm that could be caused in the event of a malfunction. The best practices for designing a safe sampling system include:

- Minimizing the number of joints and reducing tapered threads from the sampling point to the analyzer to minimize the chance of leakage

- Delivering process fluid at the lowest possible operating pressure required for sampling quality

- Restricting the volume of hazardous fluids entering the analyzer shelter to the minimum required for accurate analysis

- Capturing the vent to protect operators from hazardous or toxic compounds

- Locating conditioning or disposal components external to the analyzer shelter

Analyzer shelter safety begins with a well-designed sampling system that reliably and

safely obtains a representative sample and delivers it to the analyzer station.

Leak-prevention safeguards from the sample point, along the transport line, to the analyzer are essential for sampling system safety. Incorporate similar safeguards into the lines supplying industrial gases to the analyzer. An experienced fluid systems field engineer will be able to calculate the correct pressure and volume needed to safely and consistently deliver a representative sample to the analyzer.

Swagelok’s Role in Designing Systems for Analyzer Shelter Safety

Analyzer shelter safety is the result of multiple design decisions guided by best practices and environmental guidelines and constructed with quality components, assemblies, and materials. Swagelok has been a key participant in helping California refineries design and upgrade the sampling systems that safely and reliably deliver representative samples to analyzer shelters.

Analyzer shelter safety is the result of multiple design decisions guided by best practices and environmental guidelines and constructed with quality components, assemblies, and materials. Swagelok has been a key participant in helping California refineries design and upgrade the sampling systems that safely and reliably deliver representative samples to analyzer shelters.

Swagelok Field Engineers are available for onsite assessment of your sampling requirements. Working closely with you to understand the specific requirements of all the required analyses, they’ll recommend designs for each of your sampling needs—from the sampling point to analyzer—incorporating the required

instrumentation, components, and assemblies to ensure safe, reliable delivery of representative samples. When you’ve reviewed and approved the recommended designs, technicians will then build and test these sampling systems in our local facilities.

Swagelok Field Engineers are backed by a global team of professionals with petrochemical experience, systems built from the highest quality components, and experienced technicians who transform custom designs into reliably working sampling systems. Swagelok can be a vital partner when looking to design or upgrade your analyzer shelters.

To find out more about how Swagelok Northern California can assist you in designing and implementing safe analyzer shelters by providing expert consulation and Assembly Services, contact our team today by calling 510-933-6200.

Morgan Zealear | Product Engineer – Assembly Services

Morgan holds a B.S. in Mechanical Engineering from the University of California at Santa Barbara. He is certified in Section IX, Grab Sample Panel Configuration, and Mechanical Efficiency Program Specification (API 682). He is also well-versed in B31.3 Process Piping Code. Before joining Swagelok Northern California, he was a Manufacturing Engineer at Sierra Instruments, primarily focused on capillary thermal meters for the semiconductor industry (ASML).

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)