Share this

Selecting a Mechanical Seal Support Flushing Plan With Confidence

by Malik Durojaiye on 3/11/21 8:45 AM

Few industries in Northern California are fortunate enough to have all the in-house expertise and resources you need to confidently select the right mechanical seal support flushing plan for a specific pumping process. The reason? The numerous factors to consider when designing and assembling a mechanical seal support flushing plan. There are more than three dozen distinct plans listed in the API 682 Standard. That’s not an overwhelming number, and the standard provides details for each of the configurations, but each of those plans has a range of options to consider. The final configuration of any plan will depend on:

- Process conditions such as type and composition of the process fluid, temperature, pumping pressure, pumping cycles, and BEP for the specific pump

- Existing or planned infrastructure surrounding the pump

- Availability of plant utilities—water, nitrogen, flush fluids

- Current seal support system component technology

- Best practices for seal support system design and assembly

That’s quite a few factors to consider, but the selection process becomes a bit simpler when you classify the mechanical seal support systems into three categories—process side, between seal, and atmospheric side. A quick explanation of each will help you understand the general capabilities of the seal support system categories and the typical use cases.

Process Side Mechanical Seal Support Flushing Plans

The flow: Process side mechanical seal support systems use the fluid being pumped to maintain the required lubrication, pressure, and temperature for the mechanical seal. These plans circulate process fluids in two ways (1) from the pump discharge to the seal chamber and from the seal chamber to the pump suction (2) from the pump discharge to the seal chamber and from there to the pump suction.

API Plan 14 recirculates process fluid from pump discharge into the seal chamber and from the seal chamber to the pump suction to continuously vent the seal chamber and provide higher cooling capacity.

Use cases: More than ten different mechanical seal support flushing plans fall into this classification. These plans are commonly used for non-hazardous, non-toxic pumping. Process fluids can range from low-temperature plant water to hot water services 80°C (176°F) to boiler feeds. Highly viscous fluids that tend to polymerize and fluids with suspended solids are also candidates for process side plans.

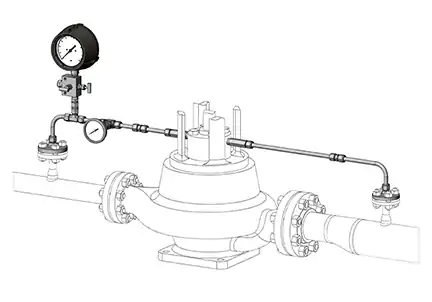

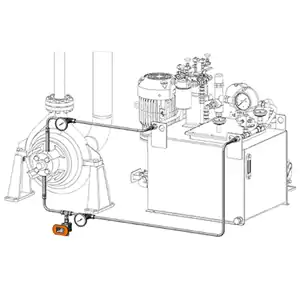

Between Seals (Dual Seals) Mechanical Seal Support Flushing Plans

The Flow: The between seal arrangement has a “primary” (inboard) seal and a “secondary” (outboard) seal. This design offers significantly better protection against process fluid leakage to the atmosphere. Barrier (pressurized) or buffer (unpressurized) buffer fluid is delivered to the seal chamber from an external source such as a reservoir or plant nitrogen. These fluids are circulated with the aid of a pumping ring or an external pump attached to the reservoir.

API Plan 55 circulates buffer fluid to and from the seal chamber via a pump located on an external reservoir. Optional filters, coolers, and components are available for this custom-engineered system.

Use cases: Dirty, contaminated, abrasive, hazardous, toxic, or polymerizing process fluids where leakage to the atmosphere presents an environmental or operational risk.

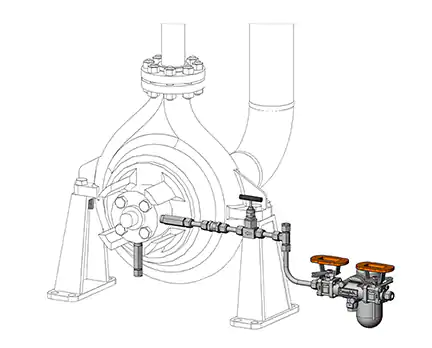

Atmospheric Side Mechanical Seal Support Flushing Plans

The Flow:

A pressureless or low-pressure quench (typically water, steam, or plant nitrogen) is delivered from an external source to the atmospheric side of a single mechanical seal. The quench cools the mechanical seal to prevent solids formation, crystalization, or coking on the atmospheric side of the seal faces.

API Plan 62 delivers quench fluid (nitrogen, clean water, or stream) to the atmospheric side of the seal.

Use cases: Hot hydrocarbon services, cryogenic processes, fluids that condense when exposed to the atmosphere, and caustic or salt services.

Guidance in Selecting Components and Options

These plans may include a range of components and design options to configure the seal support system to the specific needs of the pumping process. Instrumentation such as pressure and temperature gauges and flowmeters monitor fluid flows and alert to any changes that could result in less than ideal mechanical seal conditions. Strainers and filters remove contaminants and particulates that damage seal faces from process fluid before circulating it through the seal chamber. Coolers and heat exchangers maintain the required temperature of process and barrier fluids circulating through the seal chamber. Nitrogen, bladder accumulators, and piston accumulators are used to maintain the proper barrier fluid pressure.

The design of a mechanical seal support flushing plan requires more than just selecting one of the API 682 Plans from a catalog. To obtain the maximum value from your investment, rely on the guidance of an experienced fluid systems Field Engineer who can provide a thorough on-site or virtual assessment of the pumping process and surrounding infrastructure.

The assessment will include characteristics of the process fluid, type of mechanical seal selected for the pump, the existing or planned infrastructure surrounding the pump, access to plant utilities, and safety and environmental requirements per Cal/OHSA and/or BAAQMD. Taking those factors into consideration, the Field Engineer will then recommend the mechanical seal support flushing plan that best addresses those pumping conditions. Detailed design specifications and a bill of materials will be included for your review and approval.

Confidently Select the Optimum Plan with Expert Guidance

For well over 50 years Swagelok has worked closely with Northern California Bay Area process industries to confidently select mechanical seal support flushing plans. Our locally based Field Engineers and certified technicians provide field verification of your seal support requirements, designs based on best practices gained from global experience.

Swagelok is ISO 9001 certified and our technicians fabricate and thoroughly test your systems prior to delivery. And to give you added confidence regarding the quality of our design and fabrication process, Swagelok’s Lifetime Warranty is the industry's best.

To learn how Swagelok Northern California's local experience and global expertise can help you confidently select the mechanical seal support flushing plan for your pumping requirements, contact our team today by calling 510-933-6200.

-1.jpg?width=192&name=image8%20(1)-1.jpg) About Malik Durojaiye | Field Engineer, Assembly Services

About Malik Durojaiye | Field Engineer, Assembly Services

Malik Durojaiye began his Swagelok career in 2019 as a Custom Solutions Engineer in our Assembly Services group. Prior to Swagelok, Malik developed as a design engineer as well as a manufacturing engineer for 6 years serving Kentucky and California with Altec Industries; a leading provider of products and services to the electric utility, telecommunications, tree care, lights and signs, and contractor markets.

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)