Share this

The API Plan For Dry Gas Seal: The Basics and Beyond

by Paul Lesnau on 12/8/20 8:45 AM

.jpg?width=901&name=shutterstock_1147243691%20(1).jpg)

When you consider the variety of mechanical seal designs, there are significantly more wet mechanical seal designs than dry gas seal designs. But dry gas seals play a critical role in many petrochemical processes. It’s unlikely your undergraduate or technical school program devoted significant time to dry gas seals and their support systems, so I’ve provided a quick overview of the basics to familiarize you with their capabilities. I’ve also included some details about one of the most common API plans for dry gas seals—API Plan 74—to illustrate a practical application of the technology.

Dry Gas Seals: How They Work

Dry gas seals have non-contacting mechanical faces—a rotating ring and stationary ring. When operating, the rotating ring which has machined-in channels generates a fluid-dynamic lifting force that creates a minute gap between the two rings. Depending on the pressure of the gas being delivered to the seal chamber by the seal support system, the gas or the process fluid migrates across the seal faces. Dry gas seals are typically installed in centrifugal compressors or pumps used in petrochemical processing and gas transmission. Because dry gas seals are non-contacting, their useful life can far exceed the life of wet mechanical seals.

Dry Gas Seal Support Systems: Buffer and Barrier Gases

Dry gas seals need a supply of dry gas to maintain the required seal chamber environment. For compressors, the source is the compressor discharge which is filtered and delivered to the seal chamber at the correct pressure and flow by the seal support system. For centrifugal pumps, it’s usually plant nitrogen delivered at the proper pressure and flow by the seal support system.

When dry gas is delivered to the seal chamber at a pressure lower than the process fluid pressure, it’s called a buffer gas. At that pressure, process fluid can vaporize across the seal faces, enter the seal chamber, and be swept to a collection system or sent to flare. When dry gas is delivered to the seal chamber at a pressure above the process fluid pressure, it’s called a barrier gas because it won’t allow process fluid to vaporize across the seal face into the seal chamber.

Let’s take a look at one of the most common API plans for dry gas seals to get a better idea of how dry gas seals and their support systems work together.

API Plan 74 for Dry Gas Seals

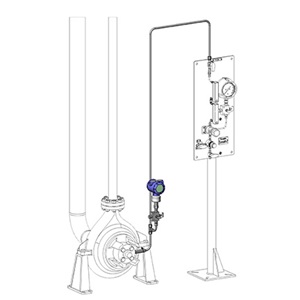

API Plan 74 delivers pressurized barrier gas, usually from the plant nitrogen supply, to a dual or tandem seal arrangement. The dual seal arrangement—a combination of an inboard seal face pair and an outboard seal face pair—provides a high level of reliability against leakage of hazardous or toxic fluids.

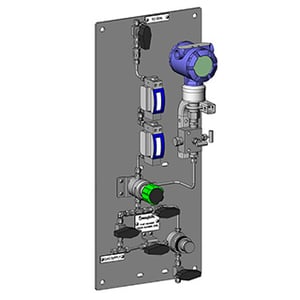

To ensure clean, dry gas is delivered, the seal support panel contains a coalescing filter to remove any moisture or particulates that might be present in the plant nitrogen supply. The absence of contaminants or particulates in the gas contributes to seal reliability.

The pressure regulator on the panel is set to supply nitrogen at least 25 psi (1.7 bar) above the seal chamber pressure. As a result of the pressure, a small amount of nitrogen will migrate through the inboard seal into the process fluid. A flow transmitter located on the nitrogen supply can alert to an increase in nitrogen use which usually indicates a seal failure.

API Plan 74 panel configured with coalescing filter, flowmeter, and pressure regulator and shown delivering barrier gas to a dual mechanical seal arrangement in a light hydrocarbon pumping process.

API Plan for Dry Gas Seals Use Cases

API Plan 74’s capability to deliver barrier gas to a dry gas dual mechanical seal arrangement provides a high level of reliability against leakage into the atmosphere. Because of these capabilities API Plan 74 is appropriate for pumps or compressors used for:

- Process fluids containing solids or particulates that would ruin seal faces

- Toxic or hazardous fluids

- High-vapor pressure fluids

- Light hydrocarbons

- Clean, non-polymerizing fluids (polymers are problematic for inboard seal faces)

For many volatile fluids that pose environmental risks if leaked to the atmosphere, API Plan 74 offers the most reliable means of preventing leakage.

Cautionary Notes for API Plans for Dry Gas Seals

Although the seal support system panel is designed to ensure dry gas is delivered at the correct pressure and flow, you’ll want to be aware of potential upstream nitrogen supply problems. An inadvertently (partially) closed valve, or crimped, bent, or leaking tubing can reduce the nitrogen delivery and undermine the reliability of the dry seal. I’ve always recommended that a bottled gas supply not be used except as an emergency backup source.

Here are a few more things to consider in managing API plans for dry gas seals. Although nitrogen is an inert gas, process engineers should ensure that nitrogen migrating across the dry seal faces will not contaminate the process fluid. In other words, nitrogen needs to be compatible with the process fluid. And even though plant nitrogen is clean, make sure you’re checking the filter on a regular basis. Maintenance of the supply line can occasionally introduce dirt into the system.

API Plan for Dry Gas Seals: Don’t Ignore These Basics

While API plans for dry gas seals may seem relatively simple, if you’re replacing oil seals in an older compressor with dry gas seals, or you’re installing a new pump, dry gas seal, and seal support system, I’ve always advised my clients to seek the guidance of experienced mechanical seal suppliers and dry gas seal support system vendors.

There are actually multiple factors to consider in planning. Process fluid composition and pumping conditions, dry gas seal design, process cycles, barrier gas compatibility with process fluid, gas supply infrastructure, location and accessibility to pump or compressor, required gas pressure, and flow.

An experienced dry gas seal vendor will help you determine the proper seal arrangement for the specific process. An experienced seal support system vendor like Swagelok will use the pump or compressor specifications and the specific dry gas seal arrangement to design, fabricate, and thoroughly test the API plan that best meets the process requirements.

Swagelok has been supporting the petrochemical industries in Northern California and Western Nevada for more than five decades. Our Field Engineers are available for on-site or virtual consultation. Based on our analysis, we’ll develop detailed renderings and technical documentation for your review and approval. An extensive inventory of the highest quality parts and components facilitates rapid fabrication and delivery of your dry gas seal support systems. Post-installation, Swagelok is always available for support via phone, email, or on-site meetings to help ensure optimal performance.

To find out more about how Swagelok Northern California can help you select the right API plan for dry gas seals for your specific process needs, contact our team today by calling 510-933-6200.

About Paul Lesnau | Sales Manager, Business Development Manager, and Field Engineer

About Paul Lesnau | Sales Manager, Business Development Manager, and Field Engineer

Paul holds a B.S. in Mechanical Engineering from North Dakota State University. Before joining Swagelok Northern California, he was the West Coast Regional Sales Manager for an organization focused within the pneumatic and hydraulic industry where he supervised product distribution throughout the western United States, Canada, and Mexico. While in this role, he was able to help provide technical and application-specific expertise to customers and distribution to drive specifications.

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)