Share this

Understanding Sampling Systems for Process Analyzers—And the Design Mistakes to Avoid

by Morgan Zealear on 12/10/20 8:45 AM

If grab sampling systems are new to you, or you haven’t had responsibility for installing or maintaining them in some time, a quick refresher will help you understand the basics. If you’re installing a new system or updating an existing one in your Northern California refinery, this information can help you avoid design mistakes that undermine efficiency, safety, and sample quality.

A well-designed grab sampling system should safely, efficiently, and consistently capture an accurate representative sample of process gas or liquid and ensure it maintains the chemical composition until analyzed by a gas chromatograph, for example. More frequently, grab sampling systems for process analyzers capture samples in bottles or pressurized metal cylinders for transport to the analyzer.

Sampling Systems for Process Analyzers—Liquid or Gas

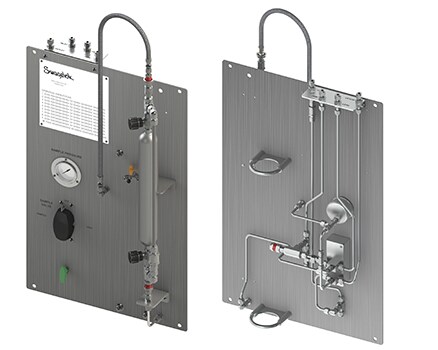

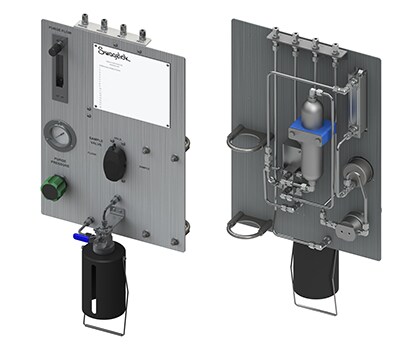

Grab sampling systems for process analyzers come in two types—gas and liquid. If you’re sampling a liquid that does not need to be pressurized in order to stay compatible and representative, you’ll be capturing the sample in a standard laboratory bottle that uses a self-sealing septum cap. If you’re sampling any pressurized liquid or gas, you’ll be using a cylinder specifically designed for the volume and type of fluid you’re capturing.

|

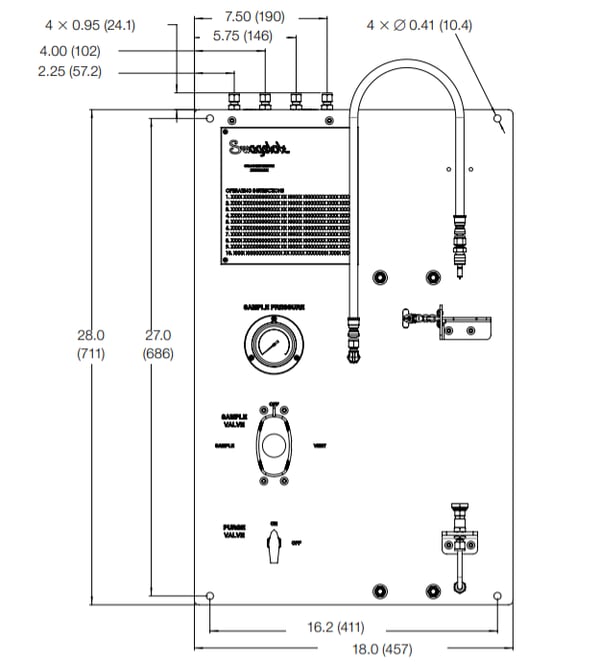

Sampling panel (front and back shown) uses sealed, pressure-containing, metal cylinders to capture liquid or gas. |

|

Design Factors Contribute to Safety, Quality, and Consistency

In my years of working with process engineers who have the responsibility of selecting and installing grab sampling systems for process analyzers in refineries in the Bay Area, I’ve concluded that good design is critical to the safety, efficiency, and consistency of the sampling process. If you think about the components that comprise a grab sampling system for process analyzers, there’s no end to the varied ways they can be configured. However, a well-designed sampling system will include key features and capabilities that help ensure the quality and consistency of samples, as well as operator safety.

|

Sampling System Features and Capabilities |

Quality |

Safety |

Consistency |

|

Captures the sample with the minimum number of sequencing steps |

✔ |

✔ |

✔ |

|

Specific sampling instructions are engraved on the sampling control panel |

✔ |

✔ |

|

|

Switching valve configuration on the sampling panel controls fluid routing and clearly indicates the sequencing steps |

✔ |

✔ |

✔ |

|

Protects the operator and environment from toxic or hazardous fluids releases |

✔ |

||

|

Purge function removes any residual contamination from sample lines with an air or solvent flush |

✔ |

✔ |

✔ |

|

Ensures that no dead leg fluid is transferred to the sampling container |

✔ |

✔ |

✔ |

|

Controls process pressure to prevent overfilling and overpressure conditions in the sample bottle |

✔ |

||

|

Uses spring-return handles on the sample draw mechanism for non-pressurized liquids to prevent unintentional dispensing |

✔ |

||

|

Includes a rupture disc or relief valve on cylinders for liquids or gasses that may rapidly expand or pressurize with increased ambient temperatures |

✔ |

||

|

Special cylinder treatments or coatings—electropolished tubing, SilcoNert®, Silcolloy®, Dursan®—reduce absorption and adsorption of sample fluids into metallic surfaces |

✔ |

✔ |

✔ |

Avoid Design Mistakes by Working With an Experienced Supplier

Each sampling system for a process analyzer may require some custom configuration, and here’s where the expertise of a local sampling system vendor with industry experience provides immediate and lasting value. An experienced supplier will work with you to understand the specific pressure, temperature, phase, and chemical composition characteristics of the gas or liquid you want to sample. That information will influence the sampling system design regarding:

- Panel layout and mounting options to ensure easy accessibility and ergonomic operations

- Standard or continuous flow sampling process

- Proper process pressure for sampling operations

- Need for purge bypass tube

- Required instrumentation—flowmeter, pressure, and temperature gauges

- Volume of containers to safely capture representative samples

- Need for specialty stainless or alloys to preserve sample conditions

When you collaborate with an experienced grab sampling system supplier, you avoid design mistakes that would undermine the efficiency, safety, and quality of your sampling process. The result is a grab sampling system for a process analyzer that is tailored to the specific needs and will provide years of reliable service.

Swagelok Is Your Local Resource for Sampling System Design and Fabrication

For well over five decades refineries, petrochemical processors, and manufacturers in Northern California and Western Nevada have been relying on the experts at Swagelok to design, fabricate, and test grab sampling systems for process analyzers. Using proven design practices and following ISO 9001 quality standards, Swagelok’s Field Engineers and certified technicians work with you to design and deliver sampling systems for process analyzers that consistently, safely, and reliably provide accurate representative samples.

To find out more about how Swagelok Northern California can help you avoid mistakes in designing sampling systems for process analyzers by providing expert consulation and Assembly Services, Contact our team today by calling 510-933-6200.

Morgan Zealear | Product Engineer – Assembly Services

Morgan Zealear | Product Engineer – Assembly Services

Morgan holds a B.S. in Mechanical Engineering from the University of California at Santa Barbara. He is certified in Section IX, Grab Sample Panel Configuration, and Mechanical Efficiency Program Specification (API 682). He is also well-versed in B31.3 Process Piping Code. Before joining Swagelok Northern California, he was a Manufacturing Engineer at Sierra Instruments, primarily focused on capillary thermal meters for the semiconductor industry (ASML).

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)