Share this

Coolant Management: Unique Teflon® hose helps chip makers keep cool

by Jeff Hopkins on 4/17/13 7:00 AM

New microchip production processes demand better hoses - and Swagelok Northern California has them

Swagelok W Series PTFE hose can pass the test. Download two product test reports on surface temperature and insulation. Product test reports »

One crucial part of making microchips is the ability to accurately control the temperature of semiconductor tools. To do that, fluids are delivered via hoses to either heat or cool the space around the tool chamber. A stable process chamber means a stable chip yield, so hoses are a critical piece of the puzzle.

Higher temperatures

For a long time, the primary heating and cooling media were ethylene glycol and deionized water. Chip design is always improving, however, and new processes are demanding higher temperatures. Now chip manufacturers prefer to use dielectric media. That brings a whole new set of challenges. Some chip fabs in Europe even had to shut down when the new high temperatures caused the old hoses to smoke.

A hose has to satisfy a chip manufacturer on many levels at once: safety, performance, cleanliness and temperature capability range. If the exterior of the hose gets too hot, that's a safety issue. If the hose surface gets too cold and water starts condensing on it, water could drip on to some other important piece of equipment. A hose that doesn't insulate well also drains away profits, because the company has to use bigger chillers and heat exchangers to make up for the temperature fluctuations in the hose.

Dielectric media

In addition, dielectric media is hydrophilic, which means it seeks out moisture. Even in a cleanroom, human beings add moisture to the air simply by breathing. So the hose must not let moisture in.

One of our customers was establishing a new platform for transferring dielectric media using fluids sold under the trade names Galden and Fluorinert. It was a big change for the company because they were upgrading to chambers twice the size they had been using. The new platform had to meet industry and OSHA requirements, and keep the fluids within a couple of degrees of specification for production. The new system also had to incorporate legacy dripless quick-connect parts.

Swagelok W series PTFE hose

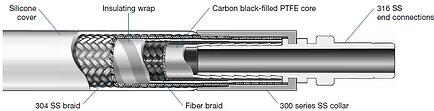

We had the answer: Swagelok W series PTFE hose. In addition to meeting all the insulation criteria, it uses a carbon-impregnated PTFE core, conveying any potential electro-static charges to ground thus preventing potential arcing. The PTFE core in Swagelok W series PTFE hose also means these dielectric fluids will be conveyed contamination-free without concern for aging.

It's a five-layer hose with lots of mechanical strength. That means it will not kink when it is properly suspended from the floor to the chiller. For this application, a sixth layer (called Fire Jacket) was added for additional insulation. A Fire Jacket cover is available as an option on many Swagelok hoses. It acts as a secondary barrier to moisture, temperature extremes and particulates.

Full bore

3/4 inch i.d.(inside diameter) W series hose also offers superior flow rates versus conventional 3/4” hose. Typical 3/4” hose has an inside diameter of 5/8 inch. W series hose is a 'full' 3/4" i.d.! It also offers significant routing advantages. Its o.d. (outside diameter) is significantly smaller than typical hoses: The o.d. of 3/4” W series hose is 1.375 inch while conventional hose can be 3+ inches. That becomes very important on a four-chamber tool, with separate supply and return hoses connected to each etching tool. That's eight hoses feeding through a bulkhead.

Product test report

To show what W series hose could do, we set up a special test. We hooked up several W series hoses to a heat exchanger, and then put thermocouples on the skin of the hoses. We charted the temperature and overlaid that line with the temperature of the fluid inside the hoses. The two lines showed how the hoses were able to insulate well and prevent heat loss. We also were able to incorporate the legacy quick-disconnect fittings, so the new designs will work on legacy systems. Product test reports »

W series hose not only passed the test, but showed that it could handle even greater temperature ranges. As production processes get more demanding, the W series hose will be able to handle it.

Versatility

W series also gives customers economies of scale. They can also use it for plasma etch, chemical vapor depostion, physical vapor deposition, as well as thin film processes. Swagelok W series hose can serve 90 percent of their tool applications.

Check out Swagelok W series hose for yourself to see all the technical advantages it can provide and then contact us if you would like to discuss your hose application. We also have a whole catalog of hose solutions ready to go to work. You can download it now.

Additional resources

Downloads

|

|

| Swagelok Hose and Flexible Tubing Catalog (88 Pages) | Swagelok Hose Selection Tutorials (35 Slides and 9 Pages) |

Related articles

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)