Share this

Swagelok Hose Q&A: When NOT to use static dissipative Teflon® Hose?

by Jeff Hopkins on 4/10/13 7:00 AM

If you were unable to attend our webinar, here are some questions you missed and access to additional hose selection tutorials

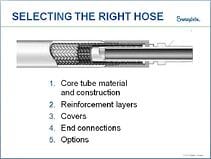

In this technical briefing, Werrlein used his twenty years of hose industry experience to give a tutorial in hose selection. You can now access Werrlein's presentation slide deck and hose selection article. Hose Selection Tutorials »

Our April 4 webinar on hose selection was well received, and presenter Patrick Werrlein answered quite a few questions from the audience at the conclusion of his presentation. We'll put the entire webinar online soon. In the meantime, here are a few of the questions Patrick tackled:

Q: You mentioned static and dynamic bend radius. Could you explain what the difference is?

A: If you look in the catalog, at the technical data, you are going to see for bend radius the maximum amount of bending that a hose can do before it starts to kink. There will be two ratings: static and dynamic. Static is where the hose would go into an orientation and stay there. If it isn't going to move, that would be a static application. Now, if we took that same application and that hose was going to do a lot of movement, moving up and down, we would then take a more conservative approach on the bend radius, factoring in the material movement. So if the hose, when static, had a six-inch radius, you may see the dynamic bend radius be more around eight inches.

Q: Is there permeability data for the different core tubes and common fluids?

A: If we had a hose that was two feet long, and another hose of the same material that was 50 feet long, put into the same application, the 50-foot hose is going to show results of a much higher rate of permeability, particularly over a period of time. That's because of the exposed amount of hose. Now, if you took the same hose product, and you put it into different types of gasses, different types of pressures, different cycling of pressure up and down, you'll find the rate of permeability is going to be all over the place. To sum it up, it's almost impossible to answer without running a test mirroring that specific application.

I would say the rule of thumb is to start with the least permeable material: You look at an all-metal hose. In a lot of cases, there is a good-better-best scenario. So maybe the all-metal hose is great from a permeability standpoint, but you have a dynamic application and there's a lot of movement. You may want to look at a material that covers both. One that may not be as good with permeation but is better against flex fatigue.

Q: Any concerns about using static dissipative Teflon® hose in an application that does not require it?

A: The only exception is going to be a pharmaceutical type of application, where you have a really sensitive media, say, a vaccine facility or a food account where you are concerned about the product coming into contact with Teflon® that has had carbon added to it. The leachable or extractable rate on those is just about zero, but there's a concern that it could happen. Outside of that, if we are talking about any general industrial application, then no.

Q: Who should be checking hoses at our plant, and what are some indications that a hose is wearing out?

A: You certainly want to make sure you partner up with companies that have the expertise. We have a global distribution network. Northern California has certified people who are fully capable of doing integrity assessments at your facility, to look for improvements of mis-installations and mis-alignments. There are some easier ones to look at. Obviously if a hose is kinked or has braid wearing, for instance, there's a potential there. The pressure containment of that hose has been jeopardized. Or if you can see where a hose is bending against its natural curvature.

Q: The 7P Series hose says it is static dissipative. Is the polyethylene also mixed with carbon?

A: The carbon in Teflon® is what makes it static dissipative. The reason Teflon® has to have carbon added is that it is such a wonderful insulator. Good insulators are bad when it comes to static charges. The 7P hose is not Teflon®, so the material itself is static dissipative.

Q: What are typical applications where you see the wrong hose being used?

A: Just to give you an example: If you have a tire press application, where you have the mold coming up and down as the tires are curing. So in these the hoses constantly move up and down. If you are looking at all-metal hose because you want something compatible with steam, and is fairly flexible, it's a good choice. However, because of the dynamic application, that metal will wear out prematurely. You probably want to go with an alternate material. For that instance: convoluted Teflon® hose. It is far more flexible, and also steam compatible.

Now, in gas applications, if you had a helium or hydrogen line, or concern of any permeation, Teflon® is probably not the ideal choice. It gives you a lot of flex characteristics; it's smooth bore, economical. But it could present some issues. I'll give you one more: a push-on rubber hose is great for ease of installation, but water at elevated temperatures has an impact over time.

For more information on hose selection, download Werrlein's presentation slides and his article, Choose the Right Hose: A Practical Guide to Hose Selection. Hose Selection Tutorials »

Additional resources

Downloads

|

|

| Swagelok Hose and Flexible Tubing Catalog (88 Pages) | Swagelok Hose Selection Tutorials (35 Slides and 9 Pages) |

Related articles

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)