Share this

Comprehension Improvement by Training Type [Chart]

by Jeff Hopkins on 4/26/18 8:45 AM

What Swagelok Field Services found when they measured effects from five steam training techniques at industrial plants

As critical as fluid systems are for industrial plant operations, too few people know how to properly use their fluid systems to their full potential. That's true even in some places where management provides training. There's a simple reason for that: not all training programs effectively convey knowledge.

Spray and pray

A poor training program is nothing more than a waste of dollars. One of the worst is the “spray and pray” method of delivering inspirational messages or running packaged videos, and then hoping for the best. For the participants, the best part of the session is the free lunch or simply a chance to get a paid break from their regular jobs.

They won't say that, of course. When management tries to get some feedback on the training session, the response is typically a noncommittal “it was good.” When managers push a little harder, asking what participants learned that could help their work performance or the fluid system’s effectiveness, they often receive an eye-opening response.

In reality, many training programs are more oriented toward selling products than changing personal behavior and sharpening everyday system operation. There's no connection between the training and the acquisition of reliable, functional knowledge of fluid systems.

Group effort

The key to changing attitudes is involvement. Effective fluid system training should incorporate discussion groups and simulation exercises that get participants involved in the topic, not just sitting there listening to videos or speakers.

When recruiting or hiring an instructor, look for one with a strong proficiency in involving students. If you can, test the instructors to learn their level of skill at delivering training content. Instructors who use stories all day long in their presentations are storytellers – not instructors.

How Swagelok Helps Praxair Stay On the Safe Side with Products, Assembly Services and Training ›

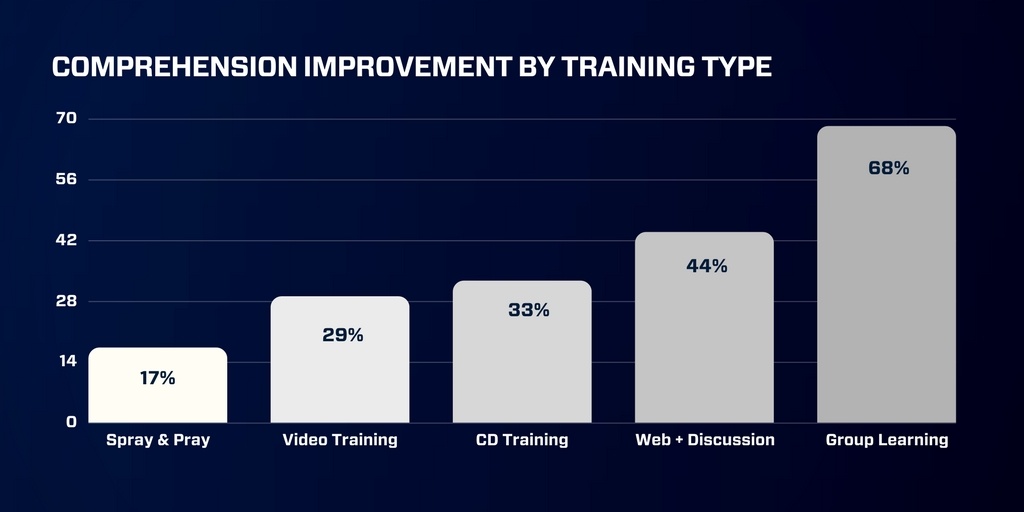

Swagelok Field Services (formerly Swagelok Energy Advisors) surveyed the comprehension levels achieved by various steam training techniques at industrial plants. Swagelok Field Services tested a variety of groups both before and after training.

Here are the comprehension levels for five different types of training:

- Spray and Pray: 17.3%

- Video Training: 29.1%

- Individual CD Training: 32.7%

- Internet Training with Interaction and Testing: 43.9%

- Group Interaction Learning with Certification: 68.3%

Group interaction is the best method of fluid system training, along with the certainty of a test at the completion of the class. Trainers need to use carefully developed exercises that assure proficiency. They need to focus on examples, and allow the attendees to execute their knowledge through exercises.

Interactive, positive learning results in better fluid system utilization, cost savings and wiser use of energy. It also creates a more positive attitude toward training in general, which sets the stage for further profitable improvements in your company's future.

Top to bottom

The most successful training programs also encompass everyone at an industrial plant, from the plant manager down to the pipefitter. Without this level of commitment, no amount of job-specific training will achieve the desired goal of maximum fluid system effectiveness.

A typical list of plant personnel who should attend training would include:

- Management

- Safety

- Environmental

- Engineering

- Production

- Maintenance supervision

- Maintenance staff

- Pipe fitters

Getting everyone involved in the training program means that everyone will have the same level of understanding of fluid systems, along with shared insights on the various solutions to common fluid system related issues.

What's next: Learn about our comprehensive training services and events coming up:

In a hurry or have a question? We are ready to help. Just ask!

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)