Share this

Helping SLAC National Accelerator Laboratory Push the Limits of Scientific Discovery

by Neil Ide on 3/15/17 8:30 AM

A Custom Panel Success: Pushing the Limits

Swagelok Northern California’s team believes in supporting the sciences and pushing industry forward — and we have since 1963. From our deep inventory of specialty parts to a wide range of technical experience, we apply our expertise to develop assembly solutions of all shapes and sizes, including those that have yet to be dreamt of.

Custom gas flow panel assemblies to support scientific research

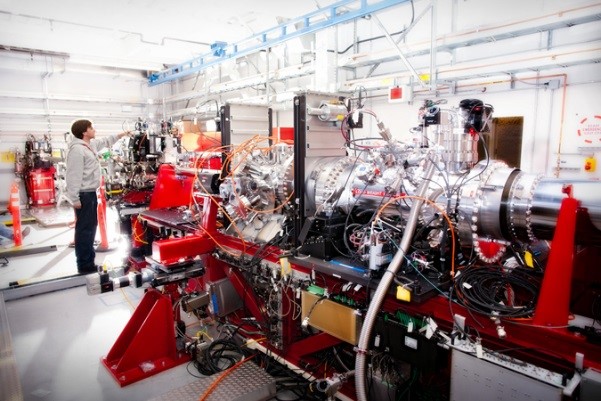

For more than 50 years the SLAC National Accelerator Laboratory (formerly known as Stanford Linear Accelerator Center), has been advancing understanding of chemistry and physics. The two-mile-long accelerator was built to accelerate electrons to nearly the speed of light to more deeply explore the nature of matter. One of the earliest fundamental discoveries by SLAC researchers was the existence of quarks. Quarks are the sub-atomic particles that make up neutrons and protons in the atomic nucleus.

Since its construction in 1962, SLAC has been upgraded several times with all manner of additional instruments such as: The Linac Coherent Light Source, the Stanford Positron Electron Asymmetric Ring (SPEAR) and Stanford Synchrotron Radiation Light source (SSLR). SLAC is home to an international community of researchers who have back-to-back experiments booked for years in advance. Once an experiment date is set it cannot be missed, otherwise the research team can be delayed for months or years waiting for another chance to get on the beam line.

A detailed look

Specialized light sources such as the free electron X-ray laser and the synchrotron radiation facility at SLAC are heavily used in photochemical research and molecular imaging to further our understanding of chemistry. Last year, Gary Rettberg, Swagelok Northern California's account manager for SLAC, received a call from Alessandro Gallo at SLAC. Alessandro needed help figuring out the right components to use to build his test apparatus. Every account manager at Swagelok knows that I’d rather die than miss the opportunity to visit a national lab and do something for the physics community; and the next week we sat down with Alessandro at his SLAC office.

The giant sculpture in the lobby and classic pictures of Richard Feynman giving lectures made the trip worth it all by themselves.

The giant sculpture in the lobby and classic pictures of Richard Feynman giving lectures made the trip worth it all by themselves.

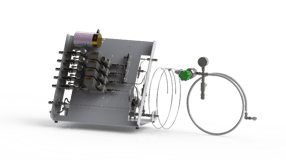

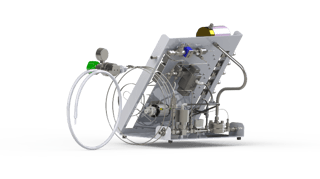

When we first met with Alessandro and his team, we learned that they had a gas phase reactor for the chemical research project on operando characterization of catalysts at SSRL and that beam time was only 16 weeks away. So, there would be just enough time to get the rest of the equipment together for the test bench. Right then and there, the scope shifted from component selection to vertical integration of the test bench for the experiment. Around a small coffee table in the break room, Alessandro and I sketched out the basic test bench gas panel diagram including remote controlled pressure regulator, six-way switching valve for volume calibration, calibrated volumes, and several mass flow controllers.

Refining the concept

After several weeks of back and forth, we finally settled on a final configuration. During the design effort, Alessandro requested help identifying the data acquisition and control equipment needed to operate the gas panel remotely. When the beam line is operating, the hutch is irradiated and not safe for humans. Any equipment in the hutch must be operated remotely. So we reached out to some experts in the field and asked for their assistance.

After all was said and done, we wound up using every bit of our 16 weeks to complete the test bench. We delivered the test equipment directly to the beam line the day before the test. I’m no stranger to laboratory equipment, and spent a good couple of hours with Alessandro and his team at the facility training them on the equipment operation.

For science!

As modern humans we often take for granted the fact that our life spans have almost tripled, we can travel hundreds of miles in less than an hour, we communicate with friends and loved ones on the other side of the globe in real time, and we enjoy nearly all the world’s information at our fingertips. We live in the future. All of these things were made possible by the work of dedicated people hurtling themselves at the limit of human understanding. Our scientists have to jump through a hundred hoops to perform an experiment to push the boundary forward. Assisting with the advancement of scientific understanding is one of the many ways we like to give back at Swagelok.

Swagelok Assembly Solutions

Innovation is essential to the team here at Swagelok Northern California, and we’re proud to provide solutions to the scientific community that help to push boundaries. From sourcing ideal parts to drafting CAD to developing brand new systems, we offer solutions for any project.

Our team strives to offer improved efficiency, flexibility, and innovation to customers in specialized industries of all kinds. Peace of mind and problem solving? That’s just what we do. Learn more about our successful work, CAD development capabilities, and how Swagelok Northern California can help with your next project by reaching out to the team today. or download our Assembly Solutions Case Study collection to learn more.

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)