Share this

How a Seal Support System Saves on the Operating Costs of Pumps

by Paul Lesnau on 8/18/20 8:45 AM

.jpg?width=641&name=image4%20(1).jpg)

The coronavirus and ongoing commodity pricing challenges have had a big impact on petrochem demand. Yet, the suits at the top are still cautiously hopeful that business will pick up again soon. Until then, many refineries are tightening budgetary belts. California Bay Area plants, in particular, are still either partially or completely idled while focusing on maintenance at least through the rest of summer.

With processing on pause, it’s the perfect time to look at where money can be saved when work begins in earnest again. Since pumps are one of the most critical and numerous equipment types in a refinery, they present a prime opportunity for that savings. And the best place to start is with the seal support system. Let me walk you through why.

How a Seal Support System Reduces Operating Costs

Seal support systems can reduce budgetary expenditures on operations in three primary ways:

- Increased mean time before failure (MTBF). A seal support system extends mechanical seal life to reduce the frequency of costly repairs or replacements.

- Enhanced inspection and maintenance efficiency. Well-designed seal support systems improve inspection and maintenance efficiency, allowing for more frequent inspections and earlier detection of nascent problems.

- Lowered environmental Risk. Reliable seal support systems reduce the incidence of seal failures resulting in leakage or fugitive emissions that lead to fines and sanctions. This is especially important in California where strict emissions oversight is the rule of the day.

These three areas are inextricably connected. Every effort to improve seal support system operating reliability reduces risk, improves maintenance efficiency, and impacts overall pump operating costs. The savings are all the more significant when multiplied by the number of pumps throughout the refinery.

.png?width=344&name=image3%20(1).png)

Seal support systems provide the

foundation for lower operating costs.

Let’s drill this down a bit more. Here’s how each of these elements work to result in cost savings.

Increased MTBF Reduces Replacement and Maintenance Costs

With almost 40 percent of pump failures attributable to seal failure, nothing has a greater influence on seal reliability than a seal support system operating effectively. A properly designed, installed, and maintained seal support system extends the life of a mechanical seal, delivering greater process continuity and lower incidence of seal replacements.

Increased MTBF for hundreds to thousands of pumps in a plant equates to lower maintenance and replacement costs. Over the lifetimes of pumps, savings can equate to tens of thousands of dollars in direct costs and much more in indirect costs like downtime. These savings can easily justify investments in the proper seal support systems.

Improved Inspection And Maintenance Efficiency

Ease of inspecting and maintaining a seal support system is also a factor in pump operating costs. The design and accessibility of seal support system components should facilitate visual inspections that provide an immediate assessment of a seal support system’s operating performance. Controls and instrumentation should be accessible without requiring an operator to ascend a ladder or stoop to check a gauge.

.png?width=300&name=image1%20(4).png)

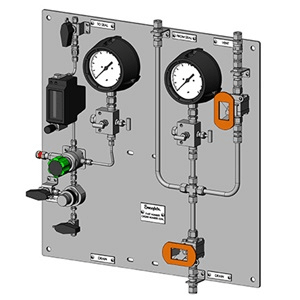

API Plan 72/76 Panel for Buffer Gas and Noncondensing Leakage Collection

In the best designs, controls and instrumentation are grouped logically on a panel for easy visibility and availability to make adjustments, conduct tests, or carry out standard maintenance procedures. Good seal support system design may also include:

- Bypass lines on filters or strainers that allow blowdown without stopping the process

- Block and bleed configurations for gauges, thermometers, and flowmeters that facilitate routine maintenance or replacement without taking a pump offline

- Clear part numbering information, flow path indication, and operator instructions to ensure safe pump and seal support system operations

Well-designed seal support systems improve inspection and maintenance efficiency. Operators spend less time evaluating seal system conditions when controls and instrumentation are easily accessible. Faster inspections allow more frequent inspections, giving operations personnel more opportunity to identify and remedy seal support system operating problems before they lead to costly pump failure.

Reduce Environmental Risk And Sanctions

More so than petrochem plants in many other parts of the U.S., Bay Area refineries must comply with some of the most stringent environmental regulations enforced by California Occupational Health and Safety (Cal/OSHA) and the Bay Area Air Quality Management District (BAAQMD). Fugitive emissions, leaks, spills, and wastewater contaminants are all potential areas of concern tied to problematic mechanical seals and seal support system operations. Although rare, catastrophic leakage can lead to significant financial sanctions and reputational damage.

Refineries can reduce the risk of mechanical seal failures that pose environmental risks by using the enterprise asset management systems (EMS) to identify pumps and processes at greatest risk. Maintenance records, fluid types, pump types, and correlations with past leakage problems should help prioritize those pumps identified. A more detailed analysis can reveal the cause of the leakage. Seal failures can be due to excessive friction, seal chamber heat, process fluid particulates, insufficient barrier fluid pressure, coking, and more.

Based on findings, you should work with their local seal support system vendor to determine the optimal solutions. The best choice of vendor will be able to provide you with a range of seal support system solutions that fit both your budget and your unique refinery applications. In addition, you should expect a lifetime warranty on any equipment investments to ensure that the cost savings continue.

Swagelok: Helping Bay Area Refineries Reduce Operating Costs For Decades

Swagelok has been serving the needs of Bay Area refineries for more than 50 years. Our field engineers provide on-site consulting, working side-by-side with reliability engineers to assess critical seal support system challenges impacting your operating costs. Design and assembly services are done locally in our Fremont facility, ensuring fast delivery of high-quality seal support systems and components. Post-installation, we’re always available for technical support and guidance regarding the best seal support system operating practices.

To find out more about how Swagelok Northern California can help you select the right seal support system when you're upgrading packing gland seals to mechanical seals, Contact our team today by calling 510-933-6200.

About Paul Lesnau | Sales Manager, Business Development Manager, and Field Engineer

About Paul Lesnau | Sales Manager, Business Development Manager, and Field Engineer

Paul holds a B.S. in Mechanical Engineering from North Dakota State University. Before joining Swagelok Northern California, he was the West Coast Regional Sales Manager for an organization based in Illinois involved in pneumatic and hydraulic applications where he supervised product distribution throughout the western United States, Canada, and Mexico. While in this role, he was able to help provide technical and application-specific expertise to customers and distribution to drive specifications.

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)