Share this

It Adds Up: Too Much Delay Hurts Analyzer Results

by Jeff Hopkins on 6/27/18 8:45 AM

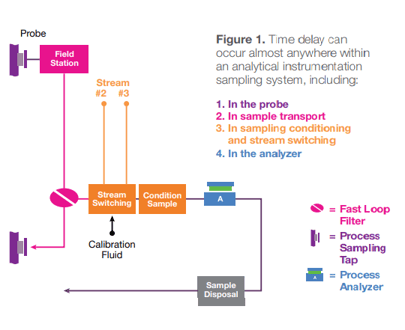

Four critical areas where samples can take too much time moving along

"In a process analyzer sampling system, there is always a delay between the moment you grab the sample and the time you obtain a reading. This time delay may be longer than you think. Underestimating it can lead to inferior process control."

- From Understanding Time Delay - Four Main Areas to Inspect

There is always a delay between the moment you grab a sample and the time you get a reading from your process analyzer. You might assume your time delay is one minute, which is the industry benchmark. But what if your assumption is way off? Your analyzer readings may no longer be relevant.

So let's go through four common causes of time delay and how you can deal with them.

- Delay in the probe

- Delay in sample transport (including the field station and transport lines)

- Delay in sampling conditioning (including stream switching)

- Delay in the analyzer

Delay in the probe

The larger the volume of a sample probe, the more delay you'll get. The probe should be long enough to reach to the middle third of the process line diameter, where the stream moves the fastest. But it's shouldn't be any longer – or wider – than necessary.

The tap location is a related issue. If you put the probe near a low-flow section of the process pipe, you'll need to wait longer for any change in the process chemicals to show up. So put the tap upstream of such sources of in-process delay, including drums, tanks, dead legs and stagnant lines.

Delay in sample transport

In the sample transport areas, expect delays due to:

- Remote Sample Tap Locations —The further a sample has to travel for analysis, the longer the delay. So put the tap as close to the analyzer as possible. For longer transport lines, consider using a fast loop to accelerate flow.

- Line Length and Diameter —The further the sample has to move and the larger the internal volume of the transport lines, the longer the delay.

- Low Pressure in a Liquid Sample Transport Line —For liquid samples, the tap location should provide enough pressure to deliver the sample through the transport lines or fast loop without a pump.

- High Pressure in a Gas Sample Transport Line —With a gas, the higher the pressure, the slower the flow. To speed up flow, lower the pressure.

Understanding Time Delay - Four Main Areas to Inspect (Technical Paper)

Delay in Sample Conditioning Systems

You’ll find delays in the following sample conditioning areas:

- Unpurged Tee-Pieces Causing Dead Legs —A dead leg is an unpurged side volume that allows molecules into and out of the flowing system media. Common dead legs include connection points for gauges, purge and bleed valves, calibration manifolds, and lab sampling points. You’ll need to purge these areas before performing sample analyses, which means more delay. Relocating a dead leg is sometimes the simplest solution.

- Adsorption of Samples on Tube Walls and Filters —When a sample touches the walls of tubing or any other solid surface, a few of molecules stick. When you’re working on a parts-per-million analysis, this loss from adsorption (or gain from desorption) can be significant. With a liquid sample, worry only when you’re measuring less than 1 ppm. For gas samples, build in sufficient wait times between switching sources to allow for the previous gas molecules to clear.

- High Internal Component Volumes — To get a representative sample and accurate analyzer readings, the entire volume of every device in the flow path needs to be purged. Minimize the size of these components when possible.

Industrial Sampling Systems, the definitive reference guide by expert Tony Waters (book excerpt)

Delay in the Analyzer

Time delay also occurs in the final analysis at the analyzer due to:

- Discontinuous Analyzer Response Times — Some analyzers take more time than others due to processes that take place inside. For example, a colorimeter needs to develop its measured color before completing an analysis, and a gas chromatograph needs to separate its measured components before analyzing them.

- Continuous Analyzer Response Times — Some analyzers run continuously, but even these do not provide an immediate result.

- Manual System Operator Response Times — When manually managing the sample analysis process, be sure to factor in some time for the operator to notice and respond to necessary system adjustments.

If you are serious about reducing time delay, we have a three-page technical paper you can download for free. Swagelok also offers sampling systems training courses where you can learn how to precisely calculate time delay and take corrective actions. When you tap into Swagelok's expertise, you won't have to wait around to measure good results.

Swagelok Grab Sampling Systems Application Guide (Catalog)

More like this:

- Tony Waters Wrote the Book on Industrial Sampling Systems (blog article)

- Technical Webinar: Pre-Engineered Subsystems (PDF download & webinar replay page)

- More Swagelok technical articles on analytical instrumentation (section of this site)

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)