Share this

Leakage: The Thief Lurking in Your Company's Fluid System

by Jeff Hopkins on 8/23/17 8:45 AM

A small leak can drain big dollars off the bottom line, and get worse over time

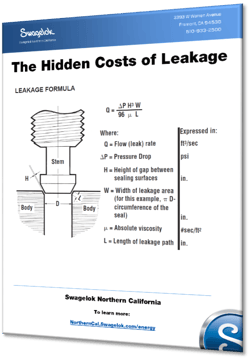

Learn how to calculate the hidden cost of leakage, download the full chapter "The Hidden Costs of Leakage" >>

Costly to ignore

How big of a problem are leaks in fluid systems? Big enough that industry associations conduct major studies to pin down the causes of leaks and ways to prevent them. Also big enough that the Swagelok Tube Fitter's Manual devotes an entire chapter to leakage. Here are a few key points from that chapter:

People often will say things such as, “A little leakage doesn’t bother us,” “Air is cheap,” or “Oil is cheap; a few drops aren’t worth saving.” They don't know how wrong they are.

It is estimated that 100 million gallons of hydraulic oil are lost each year through leakage. All that lost lubrication accounts for millions of dollars in damaged equipment. That, of course, means lost production when machines are shut down for repair.

Dripping fluid can be a safety hazard, a fire hazard and a health hazard. Even if those leaks don't hurt employees, they still might contaminate products.

Leaking dollars

The cost of a leak will vary greatly depending on what kind of fluid is leaking out (or, in a vacuum system, leaking in). One drop per second will add up to more than 400 gallons a year. For fluids costing, say, $5 a gallon, that can be up to $2,000 wasted every year. And that's just from a single leak. If you've ever spotted one leak in a fluid system, it's very likely that that there are others hidden out of sight.

Even when the only fluid involved is compressed air (a seemingly “free” fluid), it still means using extra power to keep the pressure up. A leak with an orifice of only 1/16 of an inch at 100 psig will waste 280,000 cubic feet in a month. At a cost of only 20 cents per thousand cubic feet, that's $672 wasted each year on "free" air from a single leak. Multiply these losses by the number of leaks in a facility, and the wasted money compounds quickly.

It is estimated that 100 million gallons of hydraulic oil are lost each year through leakage

If the leak results in the loss of process gases, analyzer gases, nitrogen, helium, or hydrogen, it can mean the difference between profit and loss. These specialty gasses can have costs per cubic foot in orders of magnitude more expensive. That's in addition to the cost of improperly calibrated or operating instruments, which can result in off-spec product.

We often write about the importance of a well-maintained steam system. The same benefits that makes steam a useful tool also can make it a big headache when the system has a leak. Aside from all the problems mentioned above for other fluids, steam has well-known erosive properties that usually make leaks grow larger with time.

Seek relief

If you are wondering how much leaks are costing your plant, we can help. First, Swagelok's high manufacturing standards mean that our fittings work better to begin with. Our training classes help make sure that your employees know how to install them properly. We also can utilize state-of-the-art technology to inspect your fluid system to spot leaks and give you advice on improvements, saving your facility big money.

Even small leaks can be a big headache. Contact Swagelok Northern California to bring fast relief.

additional resources

get in touch

In a hurry or have a question? Please click here to get in touch - we respond fast! Or call 510-933-6200.

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)