Share this

Minimizing the Cost of Leakage in Your Fluid System

by Jeff Hopkins on 8/29/17 8:45 AM

Start by educating yourself on the system's parts and how they work together

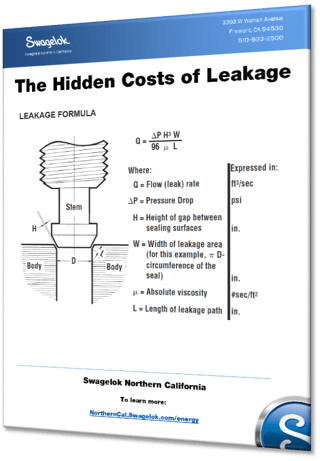

In The Hidden Costs of Leakage, learn about the main factors that go into the cost of a leak, presented uniquely via the Leakage Formula. Download the chapter now >>

Many factors

Several factors go into the cost of a leak, including the size of the leak, the amount of pressure in the system, and the type of fluid leaking out (or in). In any fluid system, however, the main goal is to minimize the cost of leakage. Here are a few things that will shrink that number.

Monitor

The earlier you can spot a problem, the faster you can fix it, and the less money you'll waste. Start a monitoring program right away. Make note of all the measurements and gauge readings when the system is operating properly. When you have a standard for comparison, it will be easier to spot anomalies. Don't wait until a leak becomes obvious. Non-operating equipment can be an additional source of leaks. Equipment no longer in use should be isolated with a valve in the distribution system.

The longer you tolerate a leak, the more it costs you.

Maintain

If you don't have a preventive maintenance program in place, set one up. Put together a list of critical or at-risk isolation valves, thread connections, regulators, hoses, gaskets and other components. Make sure everything is correctly calibrated. Conduct a leak audit at least once a year, perhaps as often as every six months.

Swagelok has several ways to spot leaks. One of the simplest is to apply one of our Snoop® liquid leak detectors. We also have some sophisticated tools such as ultrasound devices for detecting leaks in steam traps and hard to reach fittings and fluid systems.

When you find a leak, tag it. Don't remove the tag until the leak has been repaired. You may find so many leaks that you need to set up a work schedule that gives priority to the worst problems. After each leak is fixed, have someone check the repair. A poorly done repair might actually cause a new leak somewhere else.

Educate

A great way to minimize leaks from starting in the first place is to make sure that the right valve, fitting or other part has been selected for each job. We've written many times about picking the right size of a valve, gauge or regulator for a particular installation. The second element is proper installation. In many cases, leaks are caused by failing to clean the threads or by bad or improperly applied thread sealant.

The longer you tolerate a leak, the more it costs you. The sooner you fix it, the faster you'll recover the time and cost of the repair.

additional resources

get in touch

In a hurry or have a question? Please click here to get in touch - we respond fast! Or call 510-933-6200.

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)