Share this

Choosing Among Non-Contacting Seals: Making the Best Choice for Northern California Refineries

by Morgan Zealear on 9/16/21 9:00 AM

Non-contacting mechanical seals (also known as dry seals) have clear benefits in certain operations over wet seals. They have a longer useful life than wet seals, prevent contaminants and particulates from entering processes, and have a high reliability against leakage into the environment. As such, non-contacting seals—particularly API Plan 74—provide the necessary capabilities to be the preferred seal of choice for operations involving toxic or hazardous fluids, high-vapor pressure fluids, light hydrocarbons, and non-polymerizing fluids.

As can be inferred from the many petrochemical processes involving dry seals, the importance of seal selection cannot be overemphasized. It is therefore important to consult with an expert on API Plan 74 for non-contacting seals when incorporating components into operations.

Why You Should Select a Non-Contact Mechanical Seal Over a Wet Seal

Non-contacting mechanical seals provide unique characteristics that, in certain processes, are superior to wet seals. These characteristics include non-contacting mechanical faces and components that limit particulates from entering or leaving operations.

The Benefits of Non-Contacting Mechanical Faces

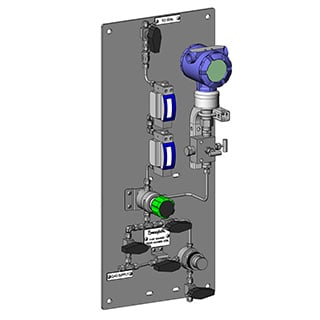

Non-contacting mechanical faces are created in API Plan 74 through generating a fluid-dynamic lifting force. This lifting force allows a small gap to be formed between the two rings—a rotation and stationary ring—in the seal. Ultimately, by virtue of being non-contacting, the useful life of these seals is significantly longer than other seals because there is less wear and tear through operation. If issues occur, the API Plan 74 has a flow transmitter that can alert users to a change in gas levels being used which may indicate a seal failure.

Limiting Particulates Into and Out of Operations

Non-contacting mechanical seals also offer additional means to prevent particulates into operations and to limit the release of particulates into the atmosphere. Dry seals create a gas barrier in a dual seal arrangement (an arrangement with inboard and outboard seal face pairs). By having a dual seal arrangement with a gas barrier, extra preventative measures are maintained to keep the internal and external environment separated. In addition, the panel contains a coalescing filter. This removes excess particulates that might be in the gas supply and contributes to seal reliability.

These advantages of non-contacting seals are directly related to their applications. As such, when considering if a dry seal is appropriate for use, it’s important to consider the substances and gases involved in processing, the contaminants likely to be encountered, and the risks to both the environment and staff.

When To Select a Non-Contacting Mechanical Seal Over a Wet Seal

When concerned about environmental leakage or contaminants, dry gas seals provide a highly reliable means to separate the internal and external environment. Similarly, non-contacting seals should be used for volatile fluids to prevent issues with coming in contact with other substances.

When Working With High-Vapor Pressure Fluids

Non-contacting mechanical seals are particularly useful for processes involving toxic, hazardous, or high-vapor pressure fluids. API Plan 74 creates barrier gas that provides a high level of reliability against leakage. The dual seal arrangement furthers this separation between internal and external environment. Some of the most common applications of dry gas seals are in centrifugal compressors or pumps used in petrochemical processing and gas transmission. The ability to work with high vapor pressure fluids is particularly useful in these situations.

To Prevent Contact With Contaminants

Non-contacting mechanical seals (such as API Plan 74) are also used for pumps or compressors that deal with substances that could ruin seal faces, have damaging contaminants in them, or could create additional risk by mixing with outside contaminants. The ability to operate without contacting seal faces allows non-contacting mechanical seals to operate with less damage to systems. Therefore, dry seals are necessary for processing involving substances with additional risks such as light hydrocarbons. Additionally, dry seals are recommended when dealing with polymers that, if in contact with seal faces, could be problematic.

If a dry seal is preferred for a process, it is recommended to seek out an expert for proper installation and to prevent future issues.

How To Choose a Non-Contact Seal Over a Wet Seal

Acquiring a non-contacting seal support plan (API Plan 74) can be achieved through contacting a local vendor with expertise on seals. It is important to correctly install non-contacting seals at the correct pressure and flow and to be aware of potential upstream nitrogen supply issues. Further, valves in the system could be damaged, tubes could be leaking, and filters in the operation could be dirty. Factors related to the process fluid—such as fluid composition and pumping, and gas compatibility—also need to be considered. Experienced mechanical seal suppliers and dry gas seal support system vendors will provide the knowledge and know-how to deal with these and many other issues while installing a non-contacting seal.

Swagelok provides non-contacting seal support plans to the Northern California region and has the expertise for the successful installation of seals. Swagelok has been a leader in providing products for industries in the areas of alternative fuels, chemical refineries, oil and gas, power, and semiconductors.

To find out more about how Swagelok Northern California can help you you with mechanical seals and all your seal support system needs, contact our team today by calling 510-933-6200.

About Morgan Zealear | Product Engineer, Assembly Services

Morgan holds a Bachelor of Science in mechanical engineering from University of California at Santa Barbara. He is certified in Section IX, Grab Sample Panel Configuration and Mechanical Efficiency Program Specification (API 682), and he is well versed in B31.3 Process Piping Code. Before joining Swagelok Northern, he was a manufacturing engineer at Sierra Instruments, primarily focused on capillary thermal meters for the semiconductor industry (ASML).

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)