Share this

Small Bore Tubing Equals Big Savings Over Pipe

by Jeff Hopkins on 11/13/19 1:00 PM

Cut installation labor costs as much as 66 percent, and save still more on operation

"Tubing is simpler, lighter, easier to install, and has fewer potential leak points; it also costs less when you factor in tools, labor, and maintenance."

- From Small Bore Tubing Solutions

The installed cost of a fluid system is only part of its total expense. If you want to eliminate unexpected spending over time on your lube systems, pneumatic systems, process control, pumps and compressors, purge systems and more, it takes proper planning and attention to detail.

Many companies use tubing systems in applications 12 mm (1/2-inch) diameter and under, while pipe continues to be the traditional choice for applications ranging from 19 to 50 mm (3/4-inch to 2-inches). Tradition, however, comes with added costs. Small bore tubing can offer a significant advantage over the life of an application.

The problems with pipe

Pipe is much thicker than tube of the same inside diameter. Both contain pressure equally well, but pipe is thicker simply to provide enough material for threads to be cut.

Consider the work associated with building or repairing pipe systems: First you must identify the series of twists and turns to run the pipe from one point to another. Each bend comes with a new joint in the system, which means threading, cutting and fitting, or welding. To get that job done, you must have all the necessary materials at the ready—pipe stands, dies, cutting oils, sealants, tapes, and more. Welding requires hydrostatic testing and can introduce moisture into the system.

Consider the work associated with building or repairing pipe systems: First you must identify the series of twists and turns to run the pipe from one point to another. Each bend comes with a new joint in the system, which means threading, cutting and fitting, or welding. To get that job done, you must have all the necessary materials at the ready—pipe stands, dies, cutting oils, sealants, tapes, and more. Welding requires hydrostatic testing and can introduce moisture into the system.

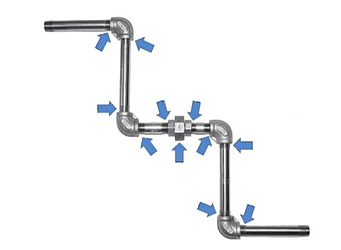

All of this precedes the actual installation. Assembling pipe requires initial cuts, de-burring, then cutting threads, followed by fitting the sections together. Any time a line must change direction, a new fitting must be introduced to the system, and each fitting is a new potential leak point.

Small bore tubing—tube with an outside diameter of 50 mm (2”) or less—can overcome these inefficiencies. Tubing offers a much more efficient strength-to-weight ratio than comparable pipe. The labor associated with tubing is also significantly less. No threads need to be cut. There is no need for oils, sealants, dies or other complicated equipment.

Like pipe, tubing must be cut and de-burred, but the similarities end there. Directional changes in tubing are made by simple bending. This eliminates the need for extra fittings while also eliminating system turbulence and pressure drop points. And because welding is not required, tubing systems are ideally suited to hazardous areas and confined or hard-to-access spaces.

It’s true that small bore tubing is more expensive than pipe, but it doesn't involve the extra expense of working with pipe. Tubing also takes a fraction of the time to install. The savings can add up quickly.

A tubing system is inherently more efficient due to minimized pressure loss, greater vibration resistance, and less susceptibility to leaks.

Getting started with small bore

Small bore tubing can deliver superior performance only when it's installed correctly. Installers must understand the right way to handle and bend tubing, and use the right equipment to ensure a successful system. They must know the correct methods for routing a line, and how to install fittings in the approved manner.

It's also important to avoid mixing and matching tube and fittings, valves, and other components from a number of different suppliers. It’s best to standardize your inventory as much as possible by sourcing critical components from a single manufacturer. You'll ensure that the parts have been specifically engineered to work together.

When you consider a switch from pipe to tubing, keep these three things in mind:

- Thorough, appropriate training for your installers will ensure that your new small bore application will be installed and maintained correctly, with the proper techniques and accounting for all necessary safety precautions.

- Some specialized tools, such as a tube bender, are required for correct installation.

- The total system —tubing, fittings, and tools — must be designed to work together to ensure a reliable, leak-free, low-maintenance system.

Just ask

When exploring a new area, it's always good to have an expert to guide you. Swagelok has been the expert in tubing and fluid systems for 70 years. Whether you have a simple question or a complex challenge, we're glad to hear from you.

More like this:

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)