Share this

Solutions to Common Plan 52 Failure Modes—And How to Get Help If You Still Need It

by Paul Lesnau on 7/14/20 8:45 AM

Leaks. They’re almost inevitable in a petrochem refinery.

But that doesn’t mean the risk they pose is acceptable—especially in California where the potential for sanctions runs high. Just one misstep in your reliability centered maintenance approach could lead to a visit from the Bay Area Air Quality Management District (BAAQMD). It might mean a slap on the wrist in the form of a reasonable fine. Or, it may turn into a protracted legal battle costing hundreds of thousands of dollars.

Preventing leaks—and their consequences—starts with selecting the right seal support plan. In the Bay Area refineries, Plan 52 is one of the most common because it is so simple and, for many applications, works quite well. Even with a solid plan in place, however, you are likely to have to do some troubleshooting when Plan 52 failure modes arise.

So, let’s go through some of the telltale signs that you have a Plan 52 seal support system problem on your hands and how to troubleshoot the root cause.

What is Plan 52?

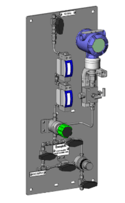

Plan 52 consists of an unpressurized seal reservoir that supplies a buffer fluid via an internal pumping ring between the inner and outer seals of a dual seal configuration. The reservoir has an internal cooling coil, typically with cooling tower water circulating through it. You will also find a pressure switch in the buffer fluid reservoir to alarm you of high pressure. Process fluid, often a light hydrocarbon, is used on the inner seal so the buffer fluid must be compatible with the current service.

This plan is typically used for relatively light hydrocarbons. It’s a clean, generic hydrocarbon service that many Bay Area plants rely on for products like jet fuel and NAPTHA. Plan 52 is especially useful when product dilution cannot be tolerated but diluted atmospheric leakage may be acceptable.

The benefits of implementing Plan 52 include:

⇨ No direct atmospheric leakage of process fluid

⇨ No process contamination

⇨ Enhanced cooling

⇨ No requirement to maintain the pressure system, unlike Plan 53A

Overall, Plan 52 is a good choice for reducing the potential for human and environmental exposure should the primary seal fail.

Signs of Plan 52 Failure Modes

When mechanical seals fail and leaks occur, maintenance engineers will often disassemble it for replacement. This provides an opportunity to look at the physical evidence of why the Plan 52 failure mode happened. For all seal systems, the four most commonly seen conditions are heat checking, pitting and corrosion on the seal face, coking, and blistering.

Let’s take a look at each one.

| Problem | Signs |

| Heat checking | This appears as small circular raised marks on the mechanical seal faces, typically due to poor lubrication. As California refiners change crude slates, be alert for process changes in your pumped fluids that may have reduced lubrication. |

| Pitting & corrosion on seal face | When you see pitting or corrosion, it’s a good signal that there is material incompatibility with the process fluid or buffer fluid. As Bay Area refineries have changed to more sour and higher naphthenic acid content crudes, corrosion has been widely seen. |

| Coking | Coke is a black carbon material that builds up on the seal face from excessive heat until it impairs the mechanical seal’s performance by either impeding the flow of seal fluid or rubbing on the pump shaft. |

| Blistering | Bubbles forming and bursting on the seal face can form from severe overheating. Blistering is typically only seen in pumps that are frequently started and stopped. |

How to Catch Plan 52 Failure Modes Early

When you find the failure signs like those above, it’s time to take better proactive action. Seal failure is no small matter; it could lead to unplanned downtime. Here is a list of things to take a look at regularly in your Plan 52 seal support system.

Flow

Verify the pumping ring is working and moving enough buffer fluid for heat removal. The result: coking. And, then, leaks.

Line restrictions

The seal support system should be made from a large enough diameter of tubing and long radius elbows to ensure the piping system is never a cause of flow restriction. Again, good buffer fluid flow is essential for heat removal.

Loss of inner seal

Make sure the pressure switch is operational. Excess pressure from a failure of the inner seal will be missed if the pressure switch is non-operational. The pressure switch allows you to plan the work of replacing just the inner seal, not both, and an orderly shutdown—prior to a potentially dangerous leak.

Cooling

Is the cooling coil working? There should be sufficient water flow and both sides of the coil should be free of excessive scale or other build up. If not, the seal system is not removing enough heat. You will eventually see the consequences.

Fluid compatibility

As crude slates change, verify the old buffer fluid is still compatible with the process fluid. While you’re at it, ensure the viscosity of the process fluid. You are relying on it to provide the same lubrication it did when the pump was first installed.

Plan 52 is pretty simple compared to some seal support systems. But, there is still a lot to keep an eye on to ensure your seal support system is providing the lubrication, seal, and heat removal it should be.

When you have questions or concerns about Plan 52 failures, it’s a good idea to have the phone number of a reputable seal support system vendor handy. They should know the ins and outs of Plan 52—and all other common systems—like the back of their hand and be available to help you troubleshoot.

Call an Expert for Any Seal Support System Failure Mode

Still have questions and not sure who to call? The refinery probably has a preferred vendor list that can answer your basic questions. But good luck getting the hands-on help you need if they are not local. You might end up on the phone for an extended period trying to explain the issue and get them to understand. And, then, you might also wait some more for the part to arrive from a faraway manufacturer.

Swagelok Northern California has an expert team of factory-trained and certified engineers who can be on-site to help with all your seal plan troubleshooting, not just for Plan 52 failures. Our Field Engineers have been working with Bay Area Refineries for years so we know the particular challenges that local crude slates pose. And we design, fabricate, and assemble all our seal plans locally. That means you can get systems and components right when you need them.

Swagelok Northern California can help with all of your Plan 52 or other seal support system evaluation, design, and fabrication needs. Contact our team today by calling 510-933-6200.

About Paul Lesnau | Sales Manager, Business Development Manager, and Field Engineer

About Paul Lesnau | Sales Manager, Business Development Manager, and Field Engineer

Paul holds a B.S. in Mechanical Engineering from North Dakota State University. Before joining Swagelok Northern California, he was the West Coast Regional Sales Manager for an organization based in Illinois involved in pneumatic and hydraulic applications where he supervised product distribution throughout the western United States, Canada, and Mexico. While in this role, he was able to help provide technical and application-specific expertise to customers and distribution to drive specifications.

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)