Share this

Swagelok And Your Smartphone

by Jeff Hopkins on 8/1/18 9:00 AM

Entrapment, dead volume, low flow areas, and trace impurities are the enemy

"... every day all over the world, thousands of people safely work right next to these chemicals. How? Swagelok VCR (vacuum coupling radius) and Micro-Fit fittings."

The standard smartphone has 2 billion transistors! How did they all get organized in harmony so you can pull data across oceans and communicate in nearly real time?

It happens behind closed doors, security stations, and airlocks in the most technologically advanced factories in the world. These semiconductor fabrication plants, known as fabs, contain miles of process piping handling some of the most advanced and reactive chemistries around. It's risky business. Contact with oxygen in the air can instantly start a fire; contact with human beings can result in far worse.

Yet every day all over the world, thousands of people safely work right next to these chemicals. How? Swagelok VCR (vacuum coupling radius) and Micro-Fit fittings. The VCR fitting was invented by Swagelok in 1966 and is the standard in semiconductor manufacturing today.

Why VCR and Mirco-Fit

In the early days, making a transistor was hit and miss. The yield was poor, costs were high, and the first transistors sold to IBM to support NASA's missions cost about $150 each! It was at that time that engineers learned that purity was extremely important. At no point in the process can outside elements be allowed to contaminate the system. Large vacuum pumps and inert purge systems constantly pump and flush the process.

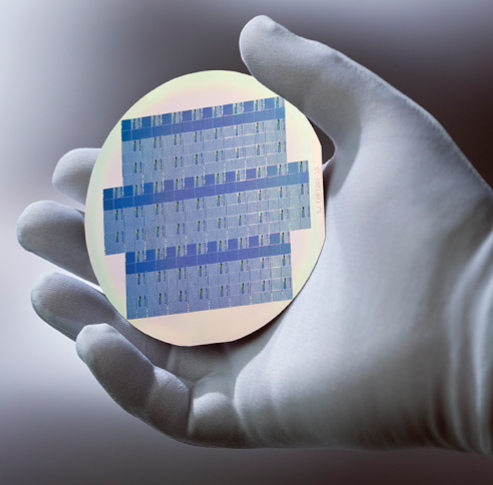

Entrapment, dead volume, low flow areas, and trace impurities are the enemy of semiconductor manufacturing and Swagelok works tirelessly to keep these out of our fittings. Dead volume and low flow areas can cause virtual leaks and chemistry hideout. Trace impurities can contaminate the process and react dangerously with chemistries.

Though traditional Swagelok fittings can handle vacuum, they are not necessarily the best solution for a high purity vacuum application. Why? Most fitting technologies were developed to contain pressure and singular chemistry. Fluid entrapment in the fitting is irrelevant for the application and goes unnoticed. In vacuum applications, entrapment zones will hide chemistry and slowly release it when pumping down to vacuum. This slow release can release chemistry into the vacuum system, making it appear like a leak. This is a "virtual leak."

Traditional Swagelok vs. VCR

Not just any 316 will do

The hallmark for corrosion resistance is 316 stainless steel, and Swagelok's careful control over chromium and nickel content make for a pure austenitic crystal structure resulting in the highest strength. Unfortunately, that simply isn't enough when it comes to high-purity systems and reactive chemistry. One of the most commonly known methods of increasing the purity of stainless steel is chemical passivation and/or electro-polishing. These processes attack free ions on the surface of the metal and remove them. By removing the surface ions, the likelihood that an impurity or free particle can react with the contained chemistry is significantly reduced. VCR and Micro-Fit fittings come in both electro-polished passivated and standard surface finishes for the purity requirement of the system.

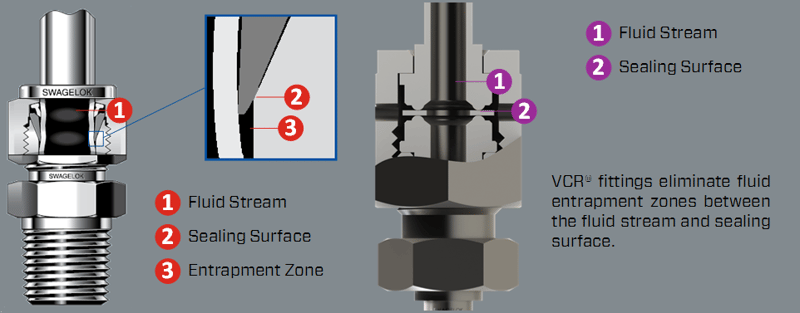

However, it's not enough to simply remove the surface ions. The metal has to have as few available ions and other impurities as possible throughout its composition. To accomplish this, the steel goes through argon-oxygen de-carburization, vacuum arc re-melting, and vacuum induction melting.

Industry standard

Today, VCR and Micro-Fit weld fittings are the industry standard for high-purity vacuum system design. There are far more options and part types for VCR and Micro-Fit fittings thank I could capture within a blog post, so for more information contact your Swagelok representative or visit us online at NorthernCal.Swagelok.com/vcr-microfit.

(Prefer to talk live? Please give us a call at 510-933-6200.)

- Swagelok VCR and Micro-Fit Fittings (page of this website)

-

A story from the front lines of Silicon Valley materials research (blog article)

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)