Share this

We Want To Pass Our Expertise Along To You

by Jeff Hopkins on 10/26/17 9:00 AM

November 8th Swagelok Tube Bending Seminar is just one of many training opportunities available from Swagelok Northern California

Sign up for the November 8th Tube Bending and/or Tube Fitting Safety Seminar on our Events page >>

Bend it like Swagelok

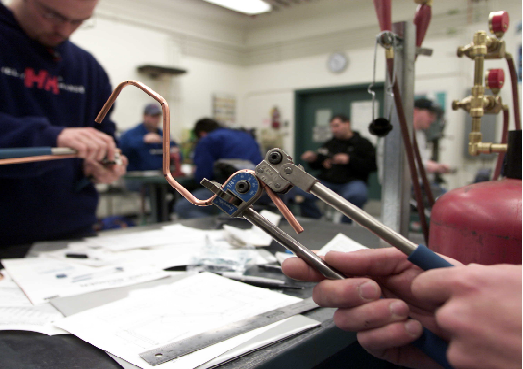

The best way to get full value from Swagelok components is to learn the best way to select and install them. And the best way to acquire that knowledge is to let our in-house experts teach you. We have a wide variety of classes to pass along our expertise, starting with our Nov. 8 class in tube bending.

Tube bending is not a skill that is taught in schools or published in textbooks. It is a skill that is normally passed from a craftsman to his apprentice. When you learn from the experts at Swagelok Northern California, you never have to worry about whether a co-worker has taught you any bad habits. With guidance from our certified expert, you'll learn how to consistently make optimal tube bends, and do the work efficiently.

We start at the beginning: How to handle tubing without damaging it. We'll show you how to properly cut and debur the tubing as well as how to bend it. You'll learn how to calculate the length of tubing you need to get from Point A to Point B. That's especially important when you are using expansion loops and offsets, which we'll also cover.

Good craftsmanship not only saves money by reducing the amount of expensive scrap, it also improves fluid system performance.

The course has hand-on exercises as well as classroom instruction, so you'll be able to practice what you just learned.

Anyone who has to install tubing can benefit from this course: fabricators, contractors and technicians. But it's also valuable knowledge for people who design fluid systems: engineers and draftsmen. Anyone responsible for inspecting or maintaining a fluid system also needs to know if the job was done right: quality control personnel and safety engineers.

Good craftsmanship not only saves money by reducing the amount of expensive scrap, it also improves fluid system performance

Other Swagelok training courses

Tube bending is only the start. We also offer classes in:

- Tube Fitting Safety. You can brush up on good fabrication procedures, review tube systems vs. pipe systems, and practice with thread sealants and lubricants. The Tube Fitting Safety Seminar is also offered, Wednesday, November 8th. Get the details on our Events page.

- VCR Metal Gasket Face Seal Fitting Installation. The Swagelok VCR Metal Gasket Face Seal Fitting has remained the preferred fitting in the semiconductor industry for high-purity gas delivery systems. The fitting must maintain a leak tight seal on some of the most highly toxic, corrosive and flammable fluids ever developed by man. With this class you'll learn how to optimize the performance of the VCR fitting.

- Introduction to Gas System Components. This course provides an introduction to the gas system components commonly used in semiconductor manufacturing as well as within the typical semiconductor process tools. The eight-hour course provides hands-on familiarization and functional knowledge of the common components found in semiconductor process gas systems.

- Valve Selection. The safe selection of the right valve for an application may appear to be a complex task. In reality it can be broken down into a repeatable step-by-step decision making process. The objective of the class is to eliminate the guess-work in valve selection; thereby minimizing ordering errors, reducing the potential for the misapplication of valves, and avoiding the costs associated with a valve failure.

- Valve Installation & Maintenance. Even the best-engineered and most precisely manufactured valve will wear with the passage of time. Poor installation and maintenance procedures can lead to premature valve failures and reduce the mean time before failure. Armed with a better understanding of a valve’s limitations and the knowledge of what can and cannot be repaired, you can greatly extend the service life of a valve.

There's no need for guesswork when our experts are ready and willing to show you the right way to get things done. Go to our training page to learn more or go to our events page to register for the November 8th Tube Bending and/or tube Fitting Safety Seminar.

additional resources

get in touch

In a hurry or have a question? Please click here to get in touch - we respond fast! Or call 510-933-6200.

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)