Share this

Why Aren't Fluid Sampling Systems Getting Any Better?

by Jeff Hopkins on 8/15/18 9:00 AM

Analyzers keep improving, but sampling systems have three strikes against them

"Many process analyzer sampling systems in today’s plants are not fulfilling their intended purpose, which is to deliver an uncontaminated, representative sample to the analyzer without excessive time delay. The result is ... inaccurate analyzer readings,...chemical and petrochemical products that are not within specifications, ...[and] safety issues."

- Dean Slejko, Swagelok Co and Tony Waters, Sampling System Expert

In the past 50 years, process analyzers of all kinds have gotten better and better, but sampling systems haven't. Many don't even fulfill their intended purpose, which is to deliver an uncontaminated, representative sample to the analyzer without excessive time delay.

The result is compromised or inaccurate analyzer readings and, by extension, chemical and petrochemical products that are not within specifications. Why? The problem can be boiled down to three main reasons.

A lack of training and learning opportunities

To our knowledge, there are no university programs that provide courses dedicated to sampling system engineering. In addition, there’s little opportunity to learn on the job. Few engineers and technicians can spare the time to attend even a one-week training course.

As a result, many major industrial companies outsourced the work to system design and fabrication specialty firms. However, even these firms have few people with the necessary skills. Inexperienced design engineers can make mistakes that may get past the reviewing engineer, who knows even less about the system. Then, if the operators need to make on-site adjustments, the designers may never learn from their mistakes.

Why Sampling Systems Haven't Improved - Three Main Reasons (Full Article)

Failure to see the whole system

Plants often consider a sampling system to be an add-on module that can be plugged into a larger system without much thought. But that ignores the process taps, the transport lines, and all the other devices that ensure the sample a suitable condition for the analyzer.

A single error along the way can bring the whole system down, and they may not be evident until the plant is at full capacity, the control loop is closed, or the laboratory results are available.

Making unauthorized changes

Most industrial plants forbid ad hoc changes to system designs. However, supervisors often push maintenance technicians to make adjustments. In this case, technicians may experiment with sampling system changes until the system seems to work better. But if the sampling system never really worked in the first place, these unauthorized changes can cause more problems than they solve.

Industrial Sampling Systems, the definitive reference guide by expert Tony Waters (book excerpt)

The path forward

So how can plants improve the quality of their sampling systems?

- Make a commitment to in-depth education and training.

- Reach out to sampling system experts who can survey and troubleshoot existing systems.

- Hold design firms responsible when new sampling systems are unreliable.

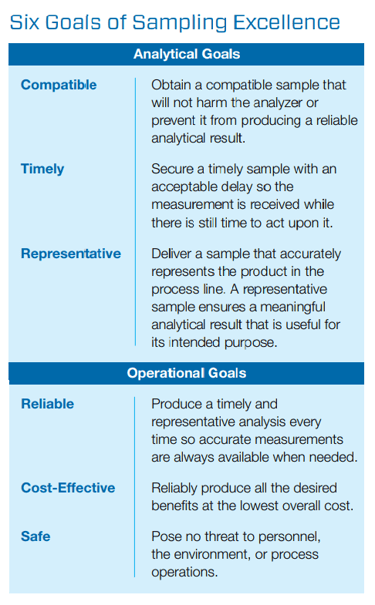

Swagelok can help in many of these areas. First, we have a three-page technical paper that goes into more detail about the areas we touched on in this post. It includes a list of analytical goals and operational goals for sampling excellence.

Swagelok Grab Sampling Systems Application Guide (Catalog)

More like this:

- Tony Waters Wrote the Book on Industrial Sampling Systems (blog article)

- Technical Webinar: Pre-Engineered Subsystems (PDF download & webinar replay page)

- More Swagelok technical articles on analytical instrumentation (section of this site)

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)