Share this

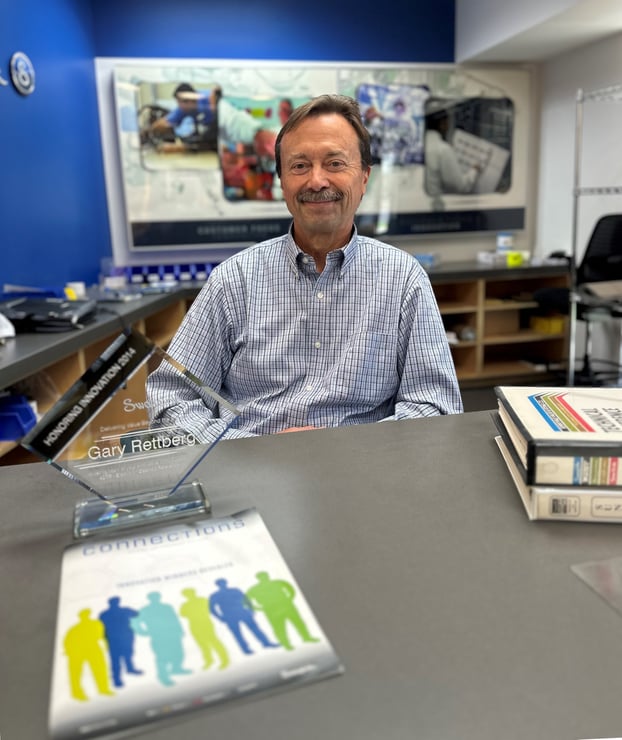

45 Years of Swagelok: Q&A with Gary Rettberg as He Nears Retirement

by Jeff Hopkins on 9/28/23 1:00 PM

When Gary Rettberg joined Swagelok Northern California in March of 1978, there is no way he could have anticipated the long journey with us through multiple innovations, economic fluctuations, and changes in the consumer landscape. But even after 45 years, Gary speaks of his job with immense enthusiasm. We recently talked with him about his early years, achievements, and challenges that kept him motivated through his long career at Swagelok.

Q: Can you tell us about your position and responsibilities at Swagelok?

Gary: My current title at Swagelok is Account Manager. The position I hold now is not that much different in day-to-day function than when I started. The Bay area population is highly educated, and the people who specify & use our products include many types of engineers and scientists. What they require from us is knowledge of our products’ capabilities and the value of using Swagelok products in their applications. My primary service to customers is providing them with the information they need to make the best possible decisions in applying Swagelok products to their specific processes.

Q: Can you tell us a bit about your background prior to joining Swagelok?

Gary: I grew up in Arlington Heights, Illinois and went to Northern Illinois University pursuing a Marketing degree. Out of college, my first job was working as a furniture store manager in the Chicago area. This was challenging, fun & a great learning experience. Around that time, a friend attending a local University encouraged me to visit the Bay area. I had never visited California, and it sounded so different from the Chicago area, that I was motivated to take the long drive across the country and see if I could get a job and start a career.

Gary: I grew up in Arlington Heights, Illinois and went to Northern Illinois University pursuing a Marketing degree. Out of college, my first job was working as a furniture store manager in the Chicago area. This was challenging, fun & a great learning experience. Around that time, a friend attending a local University encouraged me to visit the Bay area. I had never visited California, and it sounded so different from the Chicago area, that I was motivated to take the long drive across the country and see if I could get a job and start a career.

At a San Jose employment agency, I came across the Swagelok 5-company product binder. The products in the catalog were quite interesting and with my mechanical background, I wanted to know more about them. So, I requested an interview with Sunnyvale Valve & Fitting, and the rest is history.

Q: In 1978, gas was 65 cents per gallon, the first IVF baby was born, and the first Garfield comic strip was published. What were your early years at Swagelok like? What do you remember about your first day at Swagelok? Gary: Sunnyvale Valve & Fitting was a small company with about 6-7 associates in the office and an equal amount in outside sales. The first day involved 8 hours of program learning. There were Fitting and Valve binders to study and be tested on. The learning process was very thorough and went on every day for almost two months. We needed to memorize the pressure, temperature and flow specifications of every product, and all the features & benefits.

Gary: Sunnyvale Valve & Fitting was a small company with about 6-7 associates in the office and an equal amount in outside sales. The first day involved 8 hours of program learning. There were Fitting and Valve binders to study and be tested on. The learning process was very thorough and went on every day for almost two months. We needed to memorize the pressure, temperature and flow specifications of every product, and all the features & benefits.

Just as training concluded, there was a local industry show called SEMICON which was my first exposure to seeing our products used in semiconductor processing tools. It was fascinating to go around and see where the products I had been learning about were actually used. After the show, I was given a territory and a group of accounts. It was exciting to be completely free to go see customers, learn what they do, and see if we had products to help them. The early years were a great learning experience and also a lot of fun. Back then life was much simpler in Silicon Valley as compared to now…. ha, traffic was hardly an issue!

Q: Can you explain your Swagelok timeline and the roles you have held?

Gary: When it’s a small business of 15 or so associates you need to assist wherever you can, and I liked that about the job. I’ve always held the same position, although in the 1990s, my title changed to Technical Service Manager, and I was responsible for training all the new salespeople in the company and presenting new Swagelok products at our Sales Meetings. Early on customer safety & installation training was always part of the account manager role, but it was exciting to train new hires. In addition, with my marketing background, I would also assist in marketing efforts that would support sales. We published a monthly customer mailer with product and organization news titled “Technical Innovations” for many years.

Over several decades, one of my roles involved organizing new & existing product literature and assembling product catalog binders for customer distribution. As Swagelok expanded its product range, the size of our catalog binder and associated costs grew. Additionally, maintaining inventory and creating binders became more time-consuming. When Rod Fallow assumed the presidency of what was then Swagelok Sunnyvale, he tasked us with digitalizing the catalog. Collaborating with a group of former colleagues, we undertook this initiative and developed the eDTR. In recognition of our efforts, Swagelok honored us with an Innovation Award in 2014 and we were recognized in Swagelok’s Connections magazine.

Q: What does it mean to you to be a Swagelok associate/brand ambassador?

Gary: Customers respect Swagelok products and the company. For them to use the products appropriately and gain the most value, they need accurate and complete information to make good decisions.

My job as a brand ambassador is to educate and communicate all the product's capabilities. The more knowledge I have about our products and the customers’ applications & processes the better chance I have to provide them with everything they need to make optimum application decisions. It is very important to me to offer our customers an exceptional experience.

Q: What achievements/successes are you most proud of throughout your career?

Q: What achievements/successes are you most proud of throughout your career?

Gary: I consider myself to be one of the most fortunate Swagelok account managers ever. Representing Swagelok in the Palo Alto area placed me amongst many advanced technology companies and institutions. These organizations were on the cutting edge of technology which demanded extreme product performance.

The initial transition to VCR Fittings as the optimum Semiconductor process line connection as well as early integration of Micro-Fit Fittings, DL/DS, BN, DA and ALD Valves in process cabinets & tools took place in my territory. It was exciting to be part of the application & implementation of those new, revolutionary products.

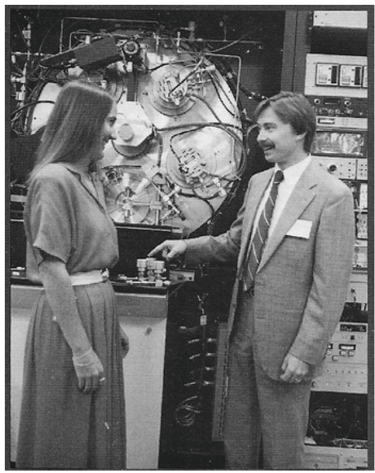

In 1988 I traveled with a team of Varian TFTD Engineers to visit Nupro and Cajon in Ohio for multi-day discussions about providing integrated welded assemblies and special purpose valves. This was a significant opportunity for us from my largest customer and in part led to a nice write-up in Varian’s Corporate Magazine. Varian TFTD evolved into Novellus PVD in the mid-1990’s which currently is a division of Lam.

Q: What have been some of the biggest challenges throughout your 45-year career?

Gary: Market fluctuations. When I first started, the semiconductor industry was very investment driven. To make chips, you need to build a fabrication facility and buy tools that require an up-front investment. Tools get purchased early to give enough time for fabrication, shipping, and installation in the fabs. Generally, once the new Fabs are built the chip-making capacity exceeds market demand. So, during the tool build cycle, there would be extreme demand for our products, which would then slow down when tools were being delivered to the fabs. That cycle curve took a long time to smooth out. Financially, it was an up-and-down ride and challenging to maintain a consistent income. Since the 2010 economic situation, global Semiconductor industry growth has been more predictable and consistent, but the current downturn indicates that the cycle is still in existence.

The other challenge is competition. Early on, many of Swagelok’s uniquely engineered products were covered by patents. We didn’t have many competitors at our level in part because the the product designs were protected. But the patents gradually started expiring, and then in what seemed like overnight, competitors began making look-alike products at lower price points. Customers were interested in talking to the competition as there is always a drive to lower costs, especially during downturns. This new competition was a great motivator for me and us us to be even more customer process focused.

Another challenge is technological changes. The advancements over the last 45 years have been amazing. The challenge is keeping up with the trends and knowing if our products need to be adjusted or improved to keep up.

Q: What has been the biggest motivating factor in this 45-year-long relationship with Swagelok?

Gary: Our products are designed and engineered to work for the long term. As Swagelok representatives, we are very proud to be selling innovative, high-quality products which involve us in some of the most advanced technologies on the planet.

Q: What things have had the biggest impact on your job over the years, and how has your role changed due to those factors?

Gary: It really has been technological change. When people ask me how I can stay in the same job for so long, I reply that it is not the same job. Every 3 to 5 years, technology leaps to the point where it is a new and different challenge with processes and systems constantly evolving. The end users of Swagelok products move at such a fast pace that it keeps the Account Manager position fun & engaging.

Q: What kept you loyal to Swagelok?

Gary: Quality products and a great, supportive organization. Customers have told me that they never worry about whether Swagelok products will work, because the engineering and quality is so reliable. But occasionally issues do arise and almost always it is due to a mismatch in application. One of the most important services I can offer customers is to be sure the product and application are a good match. Co-workers have a great deal of trust in each other, and everyone always pitches in and helps when needed. In parallel, management is very supportive and continually invests in our associates’ education and growth. Everyone is positive and goal driven, which makes for a successful company!

Q: How would you describe the growth of Swagelok in the past 45 years, and where do you see it in the future?

Gary: In the 76 years of Swagelok and my 45 years of association, all the important things about Swagelok—quality, design, engineering, and value, have remained consistent. Over my career, I have never had any concerns about the capabilities of our products, and I see that strong confidence in Swagelok continuing into the future. Swagelok will continue to support customer requirements with the best possible solutions.

It is also inspiring to see Swagelok products consistently used in systems with extreme pressures and temperatures and with challenging chemistries. Innovation to make the world a better place is always needed, and we will need quality products to control and contain those evolving applications.

Q: What is your biggest piece of advice for new Swagelok employees?

Gary: Hard work. I wish I had taken more Swagelok classes, put in longer hours and been more creative in the early years. Had I known then what I know now, I could have offered customers even more value.

That, and ask questions if you don’t know something, questions will further your knowledge and education, be inquisitive! And finally, volunteer to try new things, put your hand in the air when opportunities arise, take on new challenges and make new connections….and have fun!

Jeff Hopkins: Thank you, Gary. Speaking with you today about your long and successful career at Swagelok has been a pleasure. We hope your retirement years are even better than the last 45.

.

To find out more about how Swagelok Northern California can help you overcome design and assembly challenges for industrial process piping, tubing, and components, contact our team today by calling 510-933-6200.

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)