Share this

Choosing Among Fast Loop Gas Sampling Options: The Basics and Beyond

by Morgan Zealear on 1/14/21 8:45 AM

.jpg?width=600&name=shutterstock_1382041985%20(1).jpg)

If you’re considering installing a fast loop gas sampling system for a new process or upgrading an existing system to provide a more consistent and reliable process, it’s worthwhile to take a holistic design approach. Time invested upfront helps ensure you’ll choose the fast loop gas sampling system designed to provide years of reliable service. I’ll start with the basics, then expand the discussion to cover other factors that influence design.

Why a Fast Loop Gas Sampling System?

For sampling many non-toxic gases, a single line is all that’s needed. However, in refineries just about every gas sampling process is inherently hazardous or toxic. Cal/OSHA and BAAQMD regulations are forcing refineries to reduce flaring. For those situations, fast loop gas sampling is the only option. The system transports the gas from the source to and through a sampling cylinder with the return back to the source. For this process, a well-designed fast loop gas sampling system eliminates leakage to the atmosphere and ensures a reliable sampling process.

In comparison to a single line system, fast loop sampling offers added efficiencies. Often the sampling station is at a distance from the source. And while distance is a factor in obtaining a consistently representative sample, fast loop gas sampling transports the gas sample to the sampling station at a higher speed, reducing sampling time. To contend with longer distances, fast loop gas sampling systems use larger diameter tubing to achieve a faster flow and minimize pressure drop.

Factoring Transport Line Distance Into the Design

The distance between the gas supply and sampling station can be a factor when designing the sampling process. Gas pressure at the source, flow rate, tubing diameter, tubing volume between supply, and sampling station, sampling cylinder volume all need to be considered in determining the time required to obtain a representative gas sample from the supply. You can make it easy on yourself by relying on an experienced fast loop gas sampling vendor to incorporate those factors into the design.

Fast Loop Gas Sampling Design: Pressure and Temperature

To ensure you’re getting a consistently reliable gas sample and maintaining sample integrity as the cylinder is transported between the sampling station and analyzer, you’ll need to consider several other factors when designing a fast loop gas sampling system.

Gas sampling cylinder volume is depending on the volume required by the sampling station. You’ll want to select the minimum cylinder size that delivers the required volume to the analyzer. That will also simplify the sampling process and cylinder transport logistics.

.png?width=459&name=image4%20(3).png)

If the temperature of the sample gas is significantly higher than the atmospheric temperature, cooling in the cylinder will gradually diminish gas pressure and volume. Depending on the time required to transport the cylinder between the sampling station and analyzer, that may factor into the size of the sample volume and cylinder required.

If the temperature of the sample gas is significantly lower than the atmospheric temperature, the gas pressure in the cylinder will increase during transport to the analyzer. Placing the sample cylinder in a cooler may be required to deliver a representative sample. Alternatively, a relief valve in the cylinder can be used to avoid the dangers of increased pressure during transport.

In addition to the sample cylinder volume, the interior cylinder surface can affect sample quality. The type of gas being sampled will determine if your sampling cylinders require any special coatings such as Dursan®, Silcolloy®, or SilcoNert® to reduce adsorption and absorption of the gas into the metallic surface during transport to the analyzer station.

Fast Loop Gas Sampling: To Purge or Not

You also have the option to purge the sampling system before or after taking a gas sample. If you’re sampling non-toxic gases, it’s doubtful you’ll need the purge function. However, if you’re sampling gases that are toxic or contain condensible hydrocarbons, you’ll want to include the purge function in the design.

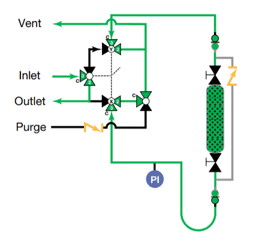

Fast loop gas sampling design for purging the fill line after taking a sample.

Typically nitrogen is the purge gas introduced to flush the fill lines in the opposite direction of filling. The purge process requires a purge-compatible sample cylinder (shown in the diagram above) to avoid purging the cylinder of the captured sample gas.

Fast Loop Gas Sampling Systems: Focus on Design and Fabrication

Fast loop gas sampling systems are designed to provide high-flow through transport lines to reduce sample time, consistently deliver representative samples, and maintain sample integrity. Achieving these design and operational goals requires an in-depth understanding of process conditions, gas properties, and the reason for the analysis. While the basic design of fast loop gas sampling systems is well understood, it’s the many other variables of a specific sampling process that require expertise in selecting the components and tailoring the final design to optimize the process.

For decades, Swagelok has been working closely with Bay Area refineries to design and fabricate fast loop gas sampling systems. Our Field Engineers consult on-site to assess the specific sampling requirements. We design the system, calculating gas flow rates, selecting tubing size, pressure gauge, flowmeter, valves, and cylinder type, and fabricate the system in our local facilities, following ISO 9001 quality standards.

Prior to delivery, Swagelok fully tests for system integrity and gas flow to ensure optimal performance. All fast loop gas sampling systems are backed by the Swagelok Lifetime Warranty and supported by Swagelok service representatives.

To find out more about how Swagelok Northern California can help greater effieciency and reliability to your gas sampling processes by providing expert consultation, desing, and fabrication, contact our team today by calling 510-933-6200.

Morgan Zealear | Product Engineer – Assembly Services

Morgan Zealear | Product Engineer – Assembly Services

Morgan holds a B.S. in Mechanical Engineering from the University of California at Santa Barbara. He is certified in Section IX, Grab Sample Panel Configuration, and Mechanical Efficiency Program Specification (API 682). He is also well-versed in B31.3 Process Piping Code. Before joining Swagelok Northern California, he was a Manufacturing Engineer at Sierra Instruments, primarily focused on capillary thermal meters for the semiconductor industry (ASML).

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)