Share this

Do It Right: Proper Tube Preparation

by Jeff Hopkins on 10/2/19 9:00 AM

A leak-tight connection starts with clean tubing cut to the right size

"Deciding which tubing to use depends on many factors. The key ones are the outside diameter of the tubing, the wall thickness of the tubing, and the material of the tubing and tube fittings."

- From FAQ: Which tubing should I use with Swagelok tube fittings?

One of the most critical processes in creating a leak-tight tube fitting connection is to properly and consistently prepare the tubing. Swagelok has created a 5-minute video (below) that goes through the four basic steps:

One of the most critical processes in creating a leak-tight tube fitting connection is to properly and consistently prepare the tubing. Swagelok has created a 5-minute video (below) that goes through the four basic steps:1. Cutting

2. Deburring

3. Cleaning

4. Inspecting

Do it right, and you will minimize any leakage in your connections caused by improper tube end preparation.

Getting started

For proper tube preparation you need a tube cutter (or a hacksaw and a tube saw guide), a tube deburring tool, a marker, a tape measure, and proper protective equipment such as gloves and safety glasses.

Before cutting the tube, inspect it for dents, scratches and other damage. If you find a damaged section, cut it off or get a different piece of tubing. If you can detect scratches with a thumbnail, they are too deep for the tubing to be used.

You also want to make sure the tubing is still round. If it has been flattened or made oval, it won't fit properly into the fitting.

Are you sure you have the right piece of tubing for the job? Look along the outer wall of the tubing and you'll see a printed "lay line" that tells you the tube size, wall thickness and material specification. Make sure all the specs match what you need for the job.

On your mark

Once you know you are ready to go, measure and mark the tubing where you want to cut it.

Once you know you are ready to go, measure and mark the tubing where you want to cut it.

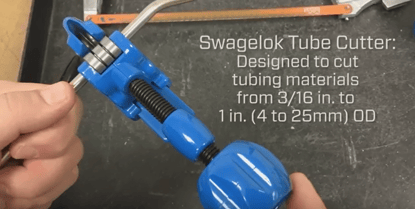

The Swagelok tube cutter is designed to cut tubing from 3/16 to 1 inch in outside diameter (or 4mm to 25 mm).

Insert the tubing into the cutter so that the mark is positioned between the rollers and the cutting wheel. Tighten the handle until the wheel touches the tubing, then give the handle an additional 1/16th turn. That's easy to do, because the turn increments on the handle are spaced in 1/8th-turn increments.

Then all you have to do is rotate the cutter around the tube. When cutting stainless steel tubing or other hard alloys, tighten the handle an additional 1/16th turn after every second rotation. For softer materials such as copper, tighten the handle after each rotation. Continue the process until the tubing has been cut through. (Always use a sharp wheel. It's the best way to minimize burring.)

But a tube cutter isn't always the best tool. For tubing with a very small diameter, a thick wall, or a diameter too large for a tube cutter, you'll be better off using a hacksaw.

You'll mark the tubing in the same way as before, but this time align the mark with cutting slot of the tube saw guide. You'll want to use a hacksaw blade with at least 24 teeth per inch, and a higher TPI may make the job easier.

Cleanup

Now that you have the tubing cut to the proper length, use the deburring tool. You may notice that the burrs you get from using a hacksaw are different than the burrs from a tube cutter. But either way, you must remove the burrs from both the outside and inside diameters of the tubing.

Now that you have the tubing cut to the proper length, use the deburring tool. You may notice that the burrs you get from using a hacksaw are different than the burrs from a tube cutter. But either way, you must remove the burrs from both the outside and inside diameters of the tubing.

The deburring tool has two ends, one to deburr the inside diameter and one to deburr the outside diameter. The process for each is the same: Place the tool over the end of the tubing and rotate the tool clockwise for four or five revolutions. Then check the tubing to make sure you have removed all the burrs. If you haven't, repeat the procedure until all the burrs are gone.

Now wipe the end of the deburred tubing with a clean cloth. You may need to use some rubbing alcohol to remove any excess oil. Dry compressed air is another good way to clean the tubing.

That's all there is to it. It's not a complicated process, but doing a proper job is essential to a leak-free fluid system.

Watch Proper Tube Preparation in action in the video below.

Just ask

Swagelok Northern California has a great deal of exposure to all aspects of fluid system design and engineering. Whether you have a simple question or a complex challenge, we're glad to hear from you.

More like this:

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)